Clenaer of chemical-mechanical polisher head

A technology of chemical machinery and cleaning devices, which is applied in the direction of grinding/polishing equipment, grinding/polishing safety devices, grinding devices, etc., can solve the problems of reduced efficiency, increased cost, and inability to clean particles, so as to achieve increased working time, Improve the effect of working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

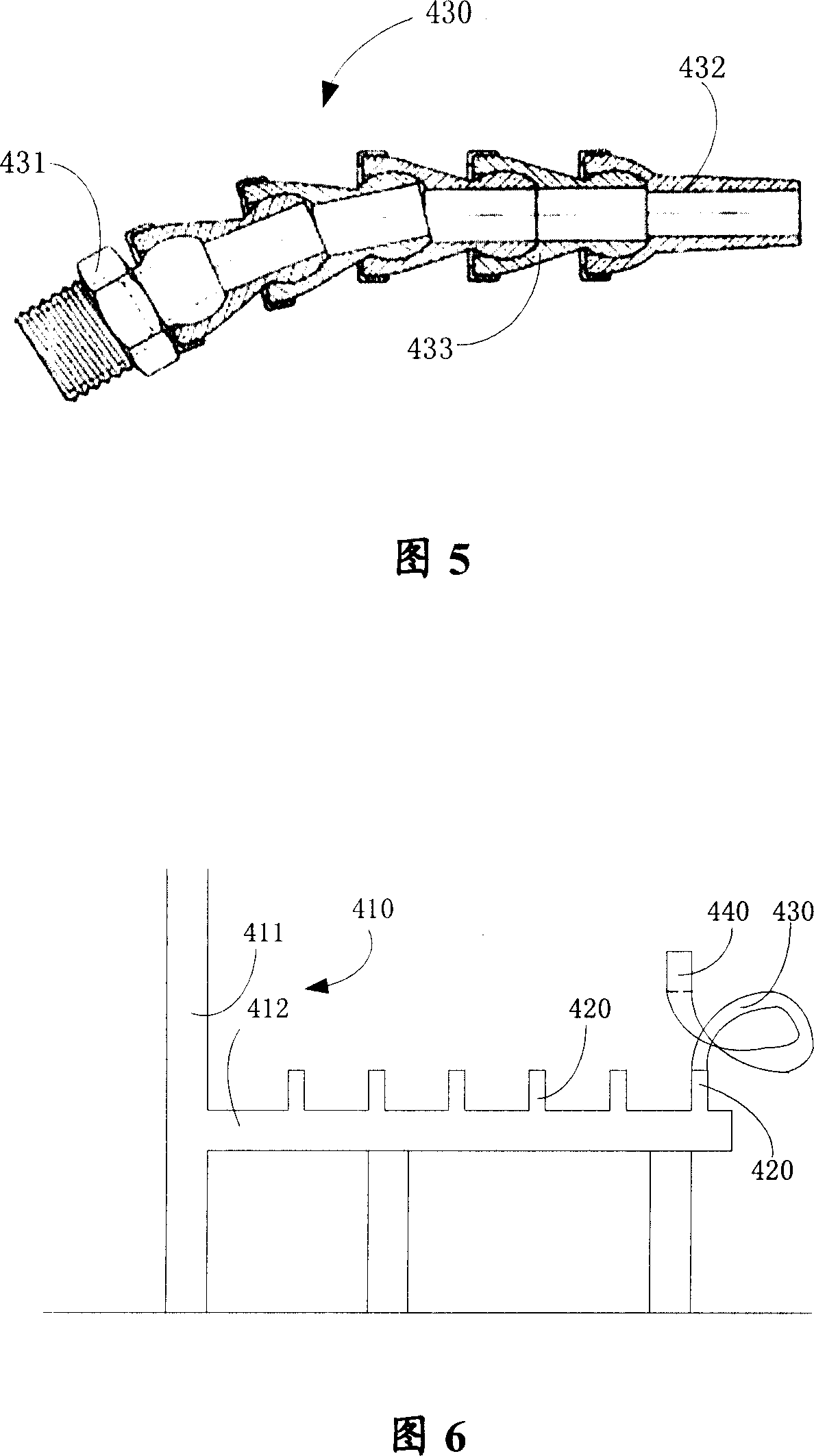

[0046] Please refer to FIG. 4 , which is a schematic diagram of a first embodiment of the cleaning device for the polishing head of the chemical mechanical polishing equipment of the present invention.

[0047] In this embodiment, the cleaning device includes a support 410 , a plurality of support nozzles 420 , a serpentine pipe 430 , a serpentine pipe nozzle 440 and a cleaning agent supply facility (not shown in the figure).

[0048] The bracket 410 is used to connect other components, including a vertical bracket tube 411 and a horizontal bracket tube 412 . The vertical support pipe 411 and the horizontal support pipe 412 are substantially cylindrical. The vertical support pipe 411 and the horizontal support pipe 412 are connected to each other.

[0049] A plurality of bracket nozzles 420 are arranged on the horizontal bracket pipe 412 for spraying cleaning agent to the polishing head 36 to clean it when it moves above the cleaning device after the polishing process.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com