Porous coal rod forming machine nose

A technology of forming machine and porous coal, applied in the field of accessories of coal rod machine, can solve the problems of high cost, unbalanced equipment operation, brittleness, etc., and achieve the effects of enhancing strength and toughness, avoiding overload tripping, and reducing water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

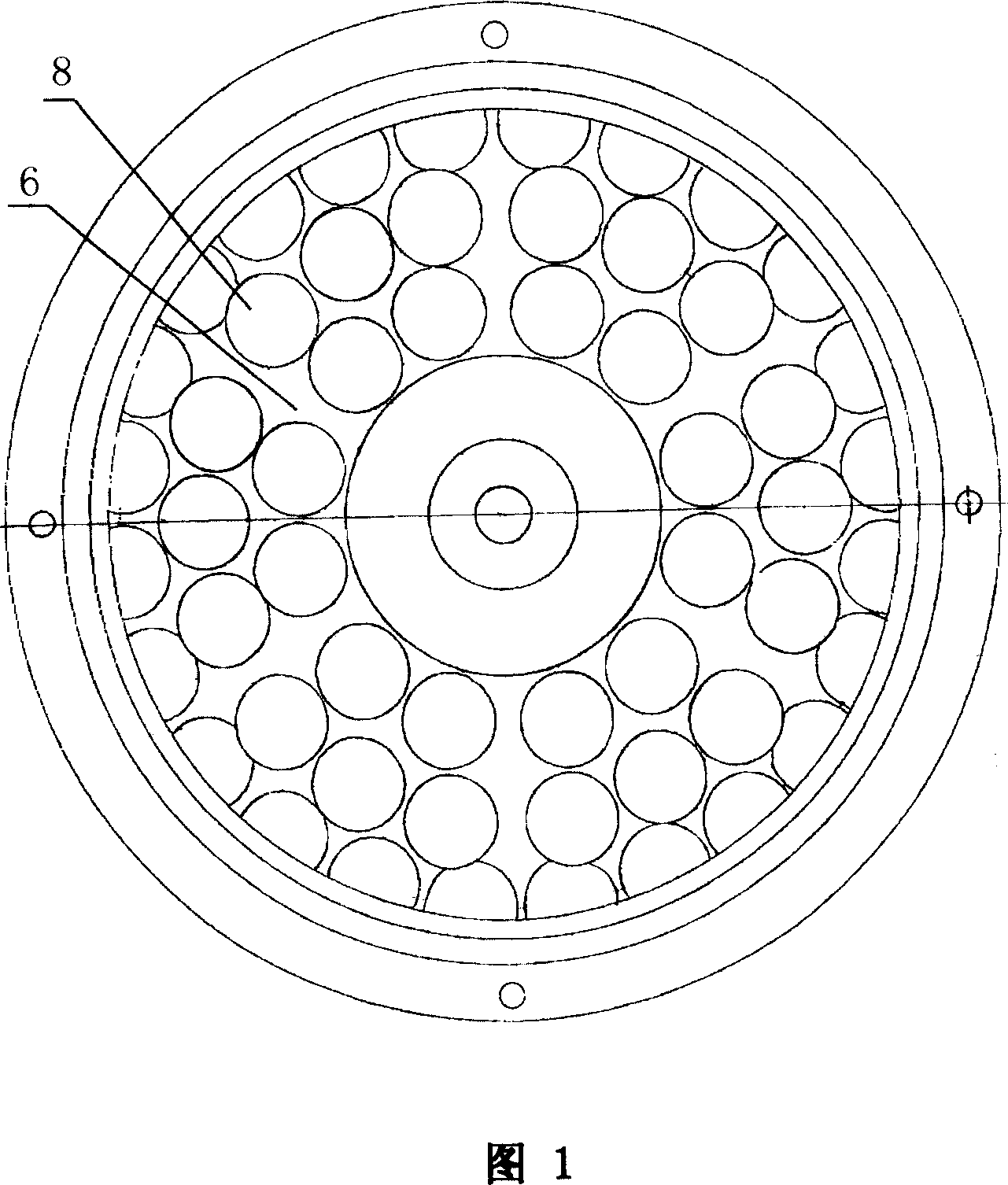

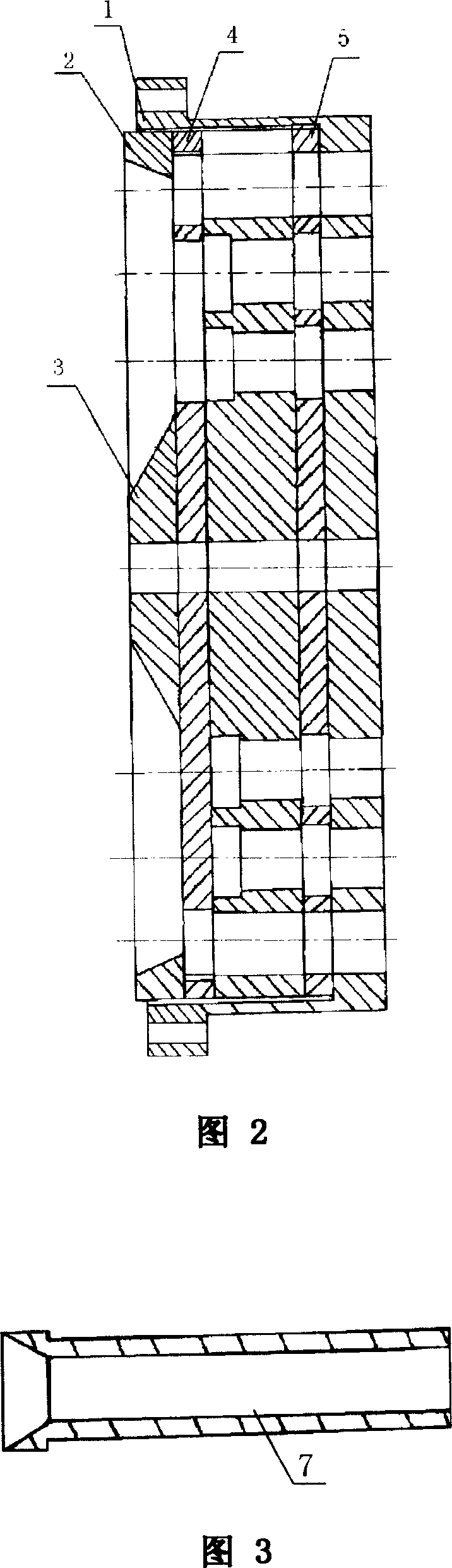

[0010] The present invention adopts the following structure: a machine head of a porous coal rod forming machine, including a casing 1 and a sealing ring 2, the casing 1 is provided with a positioning cover 3 and a shrinking tray 4, and the shrinking tray 4 is evenly distributed along a ring shape There is a grooved discharge area 6, and the grooved discharge area 6 is provided with a discharge hole 8, and the rod sleeve 7 is placed in the rod sleeve support disc 5 in the housing 1 through the discharge hole 8. Discharge holes 8 are distributed on the periphery of the housing 1 .

[0011] When the present invention is made, 12 discharge holes 9 with an inner diameter of 18 mm are evenly distributed on the circumference of the shrinkage plate 4 with a diameter of 150 mm; 24 discharge holes 9 with an internal diameter of 18 mm are evenly distributed on a circumference with a diameter of 216 mm; On the housing 1, 24 discharge holes 9 with an inner diameter of 18 mm are evenly dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com