Narrowing device for ultra-thin-walled cylindrical parts and application method thereof

An ultra-thin-walled, cylindrical technology, applied in the direction of metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of instability, wrinkling, wrinkling, etc., to save processing costs, low manufacturing costs, and avoid longitudinal failure Effects of stable wrinkling and transverse destabilization wrinkling defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

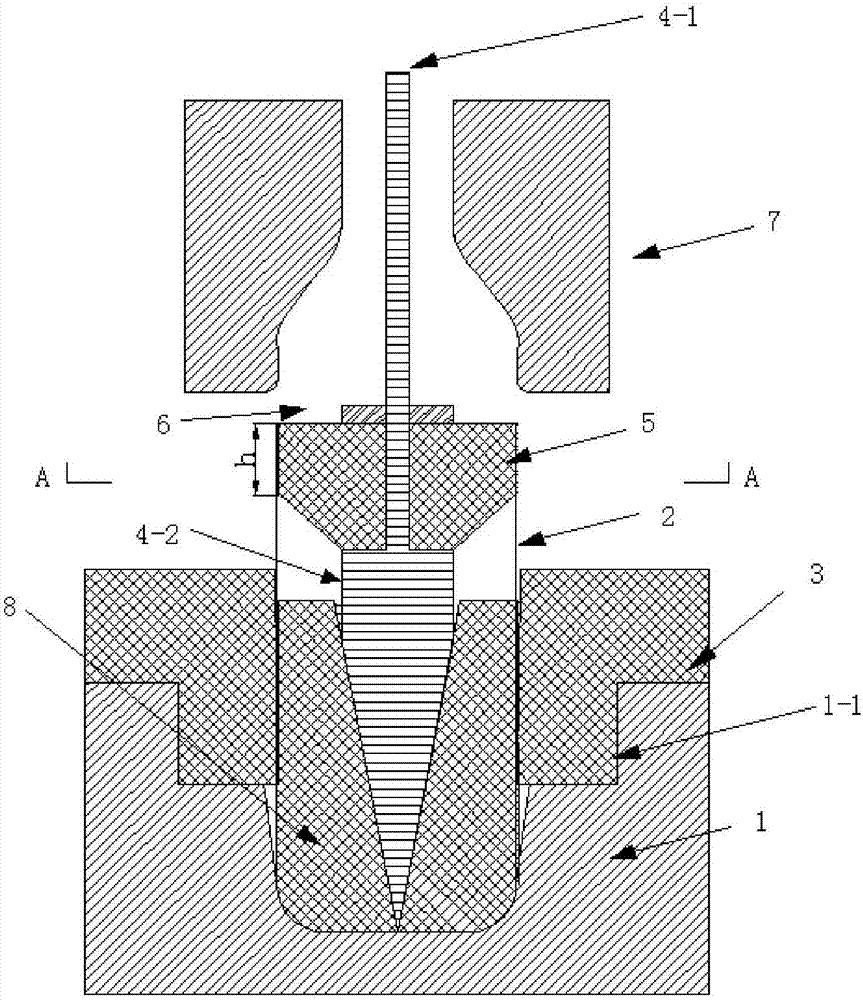

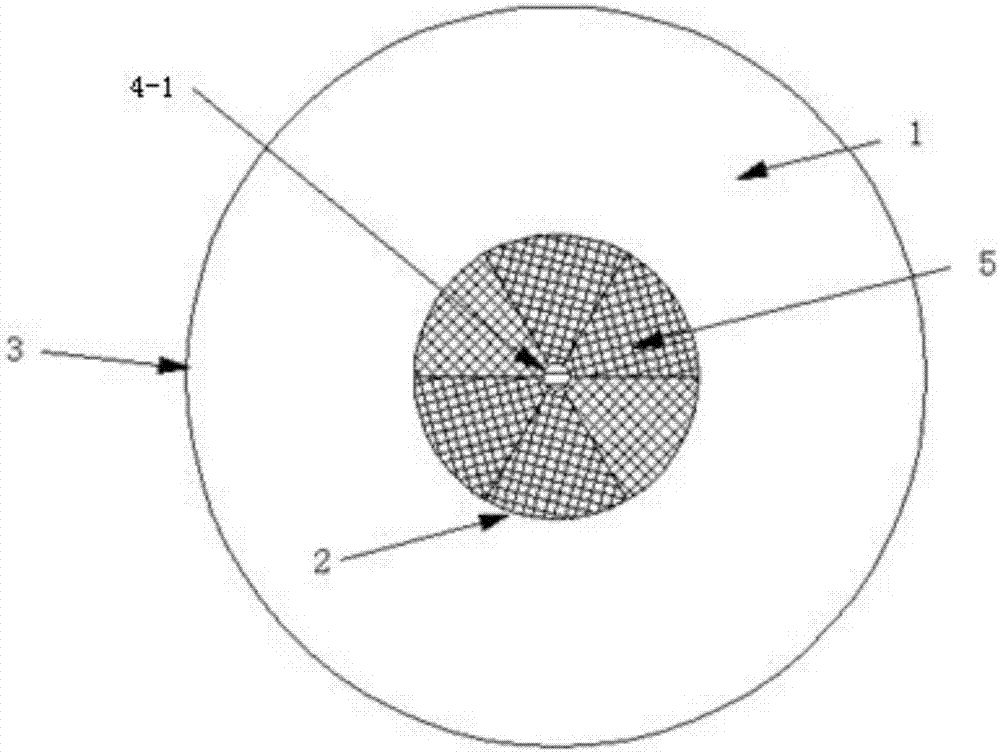

[0031] Specific embodiment 1: The necking device of the ultra-thin-walled cylindrical part in this embodiment includes a mold base 1, an outer wall support soft mold 3, an inner wall support soft mold 8, a connecting rod 4-1, a cylinder opening support soft mold 5, a positioner 6 and Shrinking die 7, wherein the lower end of the connecting rod 4-1 is connected with a conical rigid core 4-2, the rod body of the connecting rod 4-1 is provided with external threads, the mold base 1 is a concave half-cavity structure, and the cylindrical part 2 Set in the concave cavity of the mold base 1, an annular groove 1-1 is opened on the cavity wall of the mold base 1, and the outer wall with a "T"-shaped longitudinal section supports the soft mold 3 and is embedded in the annular groove 1-1 of the mold base 1 In the center of the outer wall supporting soft mold 3, there is a round hole with the same outer diameter as the cylindrical piece 2, and the inner wall supporting soft mold 8 compose...

specific Embodiment approach 2

[0033] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the mouth support soft mold 5, the inner wall support soft mold 8 and the outer wall support soft mold 3 are made of insulating resin, polyurethane, soft rubber, polypropylene or silicone material .

specific Embodiment approach 3

[0034] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the height h of the outer straight wall of the mouth support soft mold 5 is not less than the height of the mouth straight wall of the cylindrical part 2 after shrinking.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com