Track type environment inspection robot for electric power system

A technology for inspection robots and power systems, applied in the field of environmental inspection, can solve the problems of high cost, heavy workload, negligence and other problems of transformation, and achieve the effects of ensuring image stability, increasing shrinkage ratio, and reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

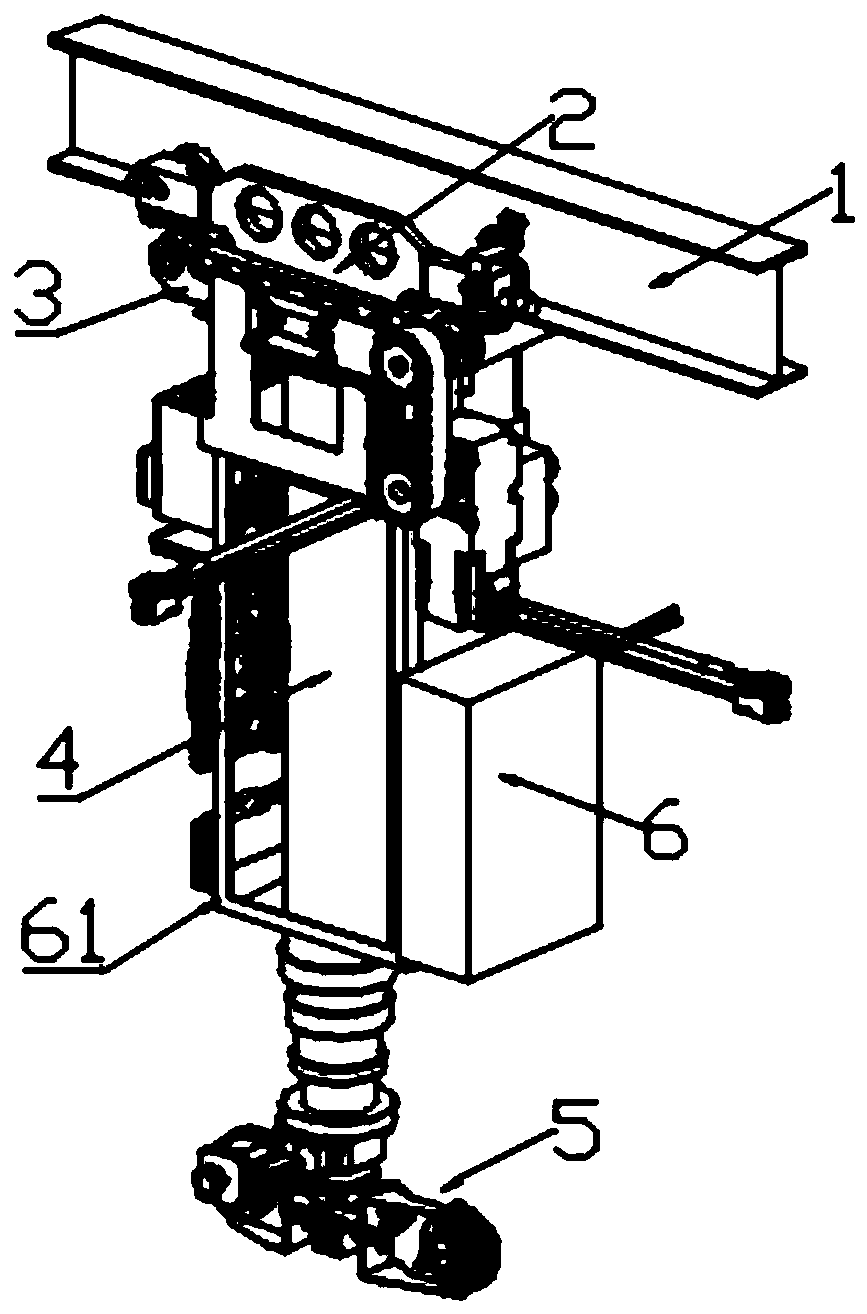

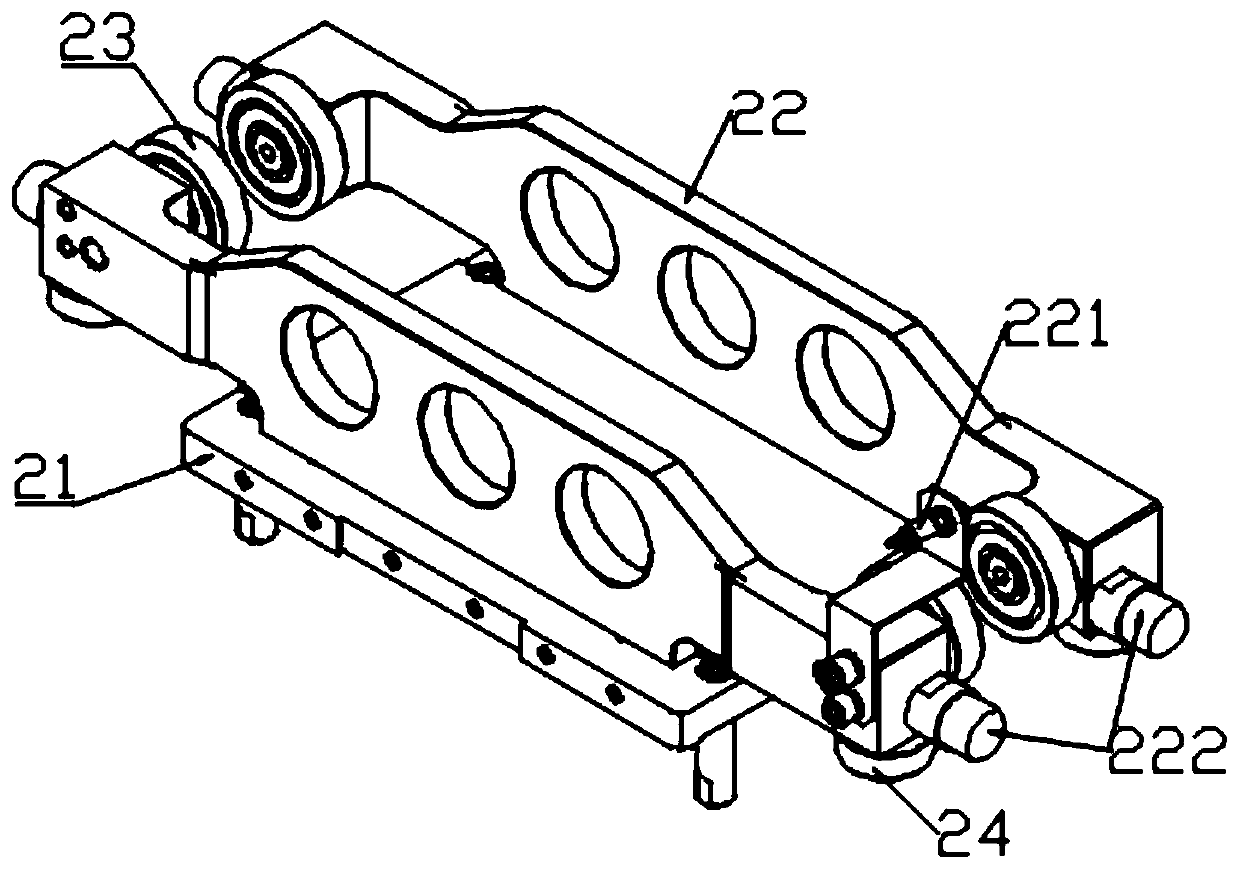

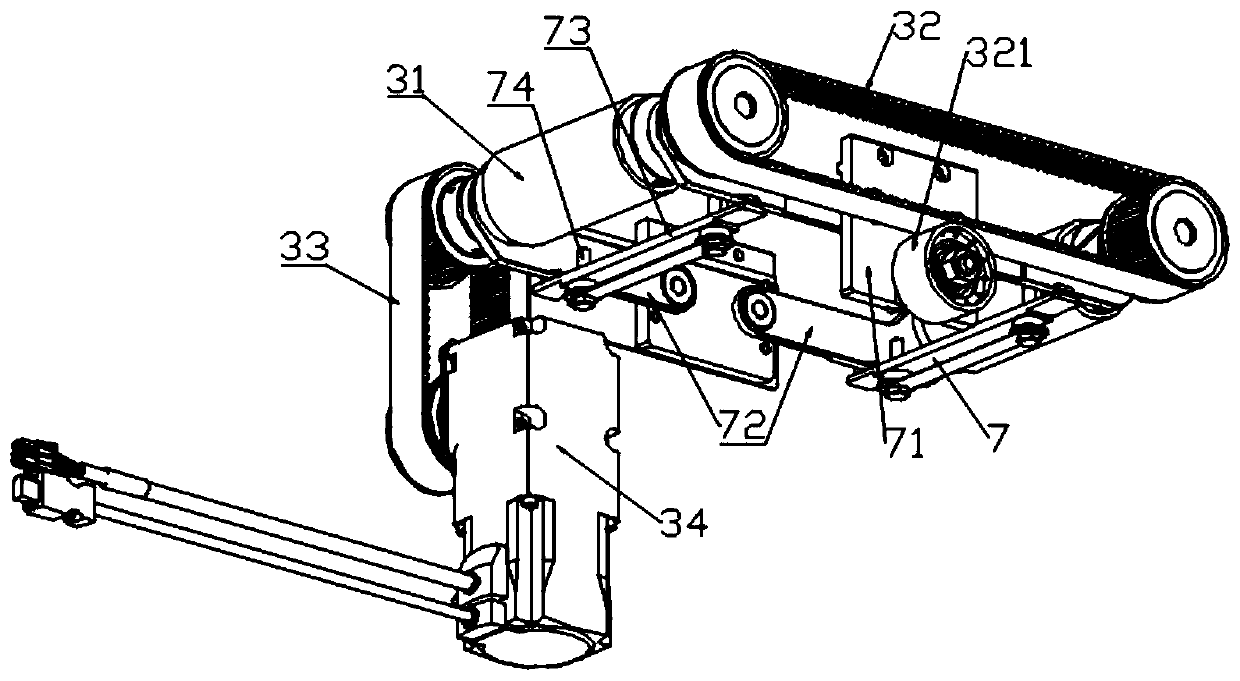

[0029] refer to Figure 1 to Figure 6 As shown, the present invention provides a track-type environmental inspection robot for power systems, including an I-shaped driving track 1, a driving mechanism 2 that walks on the driving track 1, a running mechanism 3 that drives the driving mechanism 2, a lifting The rotating mechanism 4, the monitoring device 5 and the electric control device 6, the driving track 1 is preferably a standard aluminum alloy I-shaped aluminum, which is cut or bent according to the on-site route requirements, and each section of the track is connected by a standard connector. The steel hoisting tool is suspended at a high place on the job site, and the driving track 1 is suspended in the air with a height of 2.4 meters from the ground and no slope at the level. The electric control device 6 includes an electric control bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com