Self-repairing explosion-proof tyre with multiple sub-tyres and its self-repairing method

A tire, self-repairing technology, applied in tire parts, transportation and packaging, vehicle parts, etc., can solve problems such as inability to individually replace, slow deflation, and inability to quickly distinguish, to avoid traffic accidents, facilitate replacement, and maintain consistency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

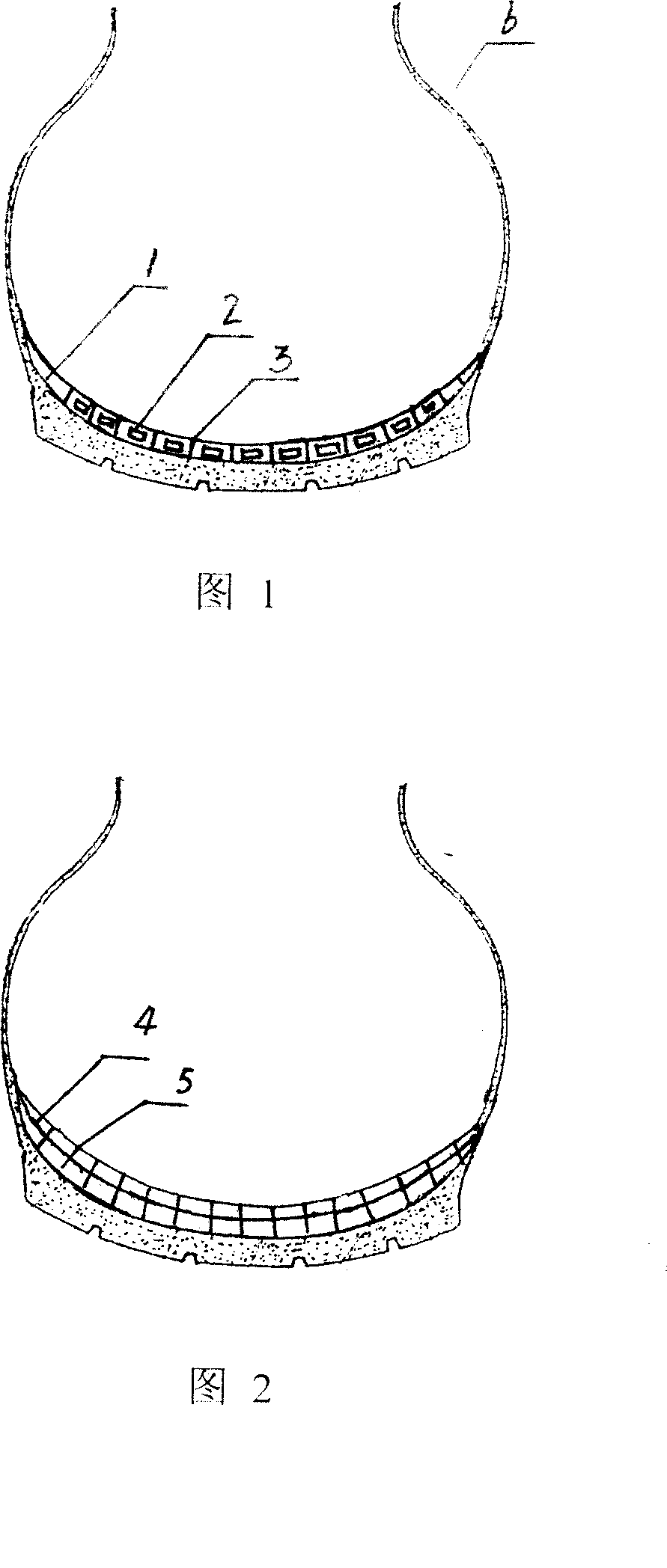

[0010] Embodiment 1: with reference to accompanying drawing 1 and 2. Self-replenishing tire, the inner layer of cover tire 6 is provided with single-layer liquid chamber 1, and chemical reaction liquid is housed in the single-layer liquid chamber. The single-layer liquid chamber 1 is built with coagulation reaction liquid, and each layer is divided into multiple non-conductive spaces 3, and each space is filled with coagulation reaction liquid. The manufacturing process of the single-layer liquid chamber 1 composed of multiple small liquid chambers that are not connected to each other and the injection of the coagulation reaction liquid in the small liquid chamber are all prior art, and will not be described here.

Embodiment 2

[0011] Embodiment 2: On the basis of Embodiment 1, the single-layer liquid chamber 1 is built with a layer-wrapped solidification reaction bag, and each layer is divided into a plurality of spaces 3 that are not connected to each other.

Embodiment 3

[0012] Embodiment 3: On the basis of Embodiment 7, the single-layer liquid cavity 1 is built with an expansion body 2 and each layer is divided into a plurality of spaces 3 that are not connected to each other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com