Multi-meridian tyre self-complementary explosion-proof tyre

A technology for run-flat tires and multiple sub-tires, which is applied in the field of tire manufacturing, can solve the problems of inability to quickly distinguish, slow deflation, and cannot be replaced individually, so as to avoid traffic accidents, facilitate replacement, and maintain consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

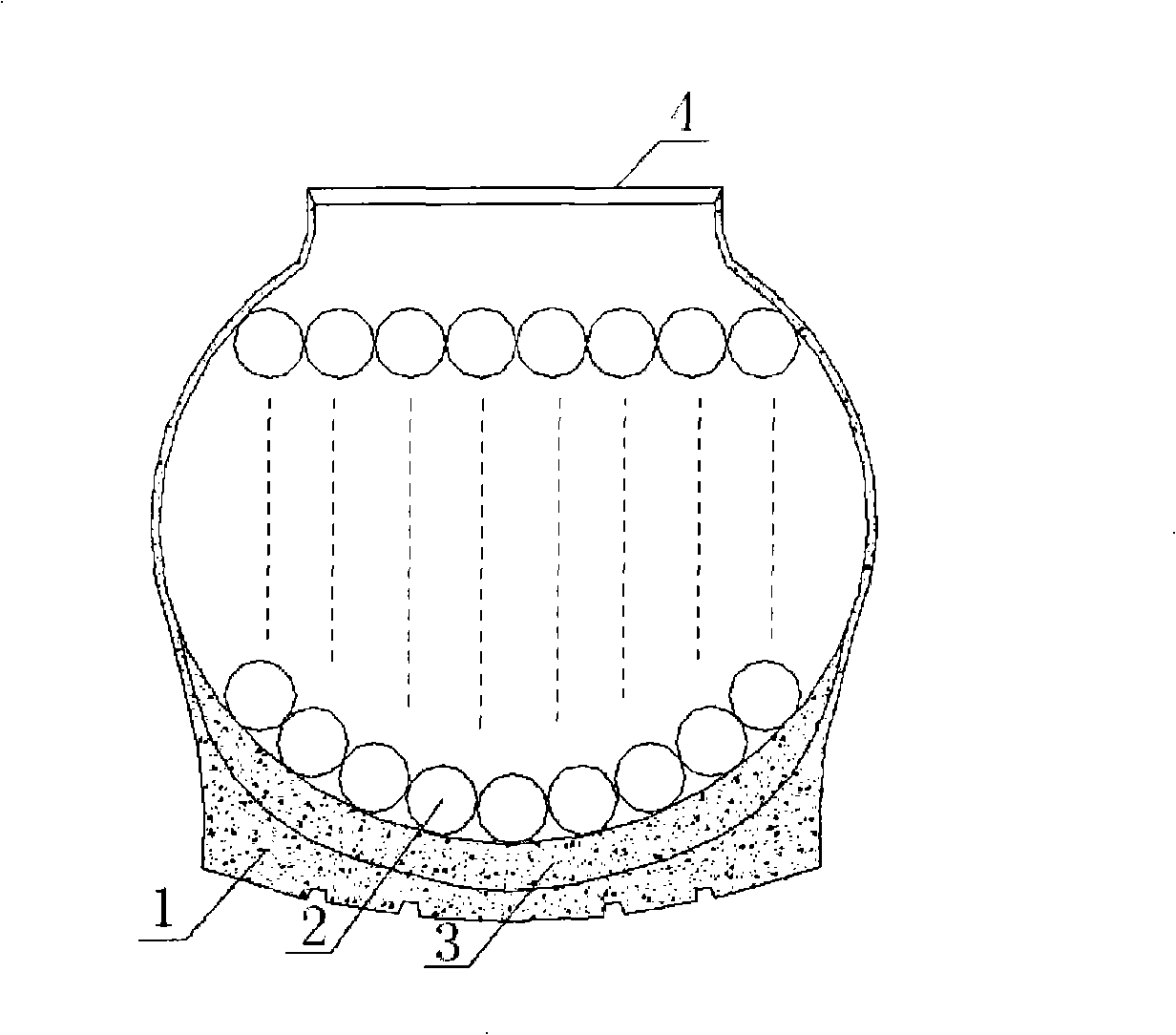

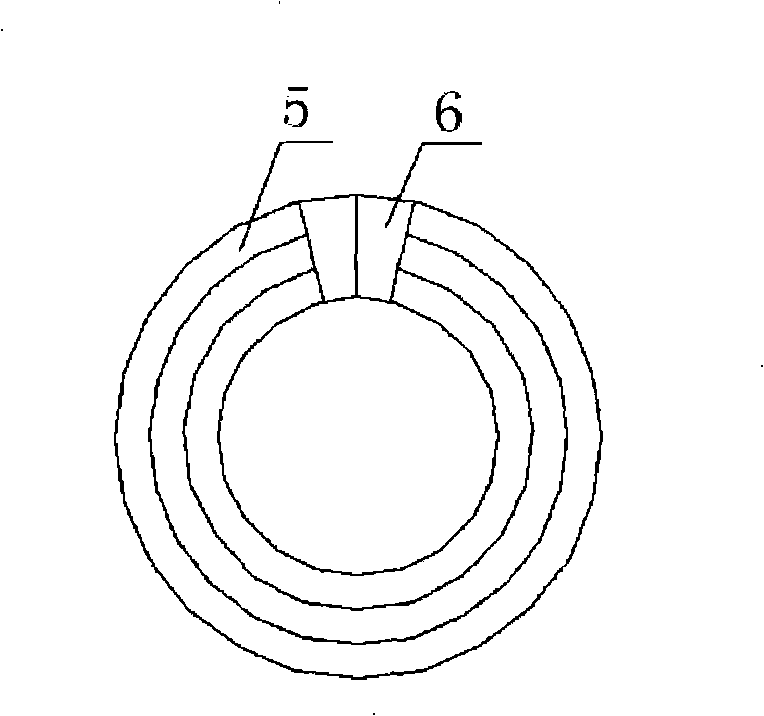

[0010] Embodiment 1: with reference to accompanying drawing 1~3. Multi-tire self-replenishing explosion-proof tire, which includes a wheel hub 5 and a tire 1, the inner tire 2 in the tire 1 is composed of 2 or more sub-tires, and a metal chain plate 3 is placed inside the outer tire. The sub-tires are When the elbow clip wedge 5, the sub-tire was full of gas, without air valve, and the wedge-shaped air block 7 was used to make up the wedge-shaped space produced by the elbow, and spare inner tube 6 was equipped with on its wheel hub 4 and was provided with air valve.

[0011] The method of replenishing air for self-replenishing run-flat tires with multiple sub-tires, when one or two or more sub-tires in the outer tire are punctured and the tire pressure cannot reach the range of its set value, ① the air pressure sensor in the tire after detection When there is a signal of insufficient air pressure, instruct the air pump in the car to inflate the spare inner tube at the place of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com