Strape weaving rebounder making process and apparatus

A technology of trampoline and mesh, which is applied in the field of preparation of trampoline mesh, can solve the problems of high price, impact on safety, and influence on the elasticity of trampoline mesh, and achieve the effect of good price ratio, low production cost, and promotion of trampoline exercise level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

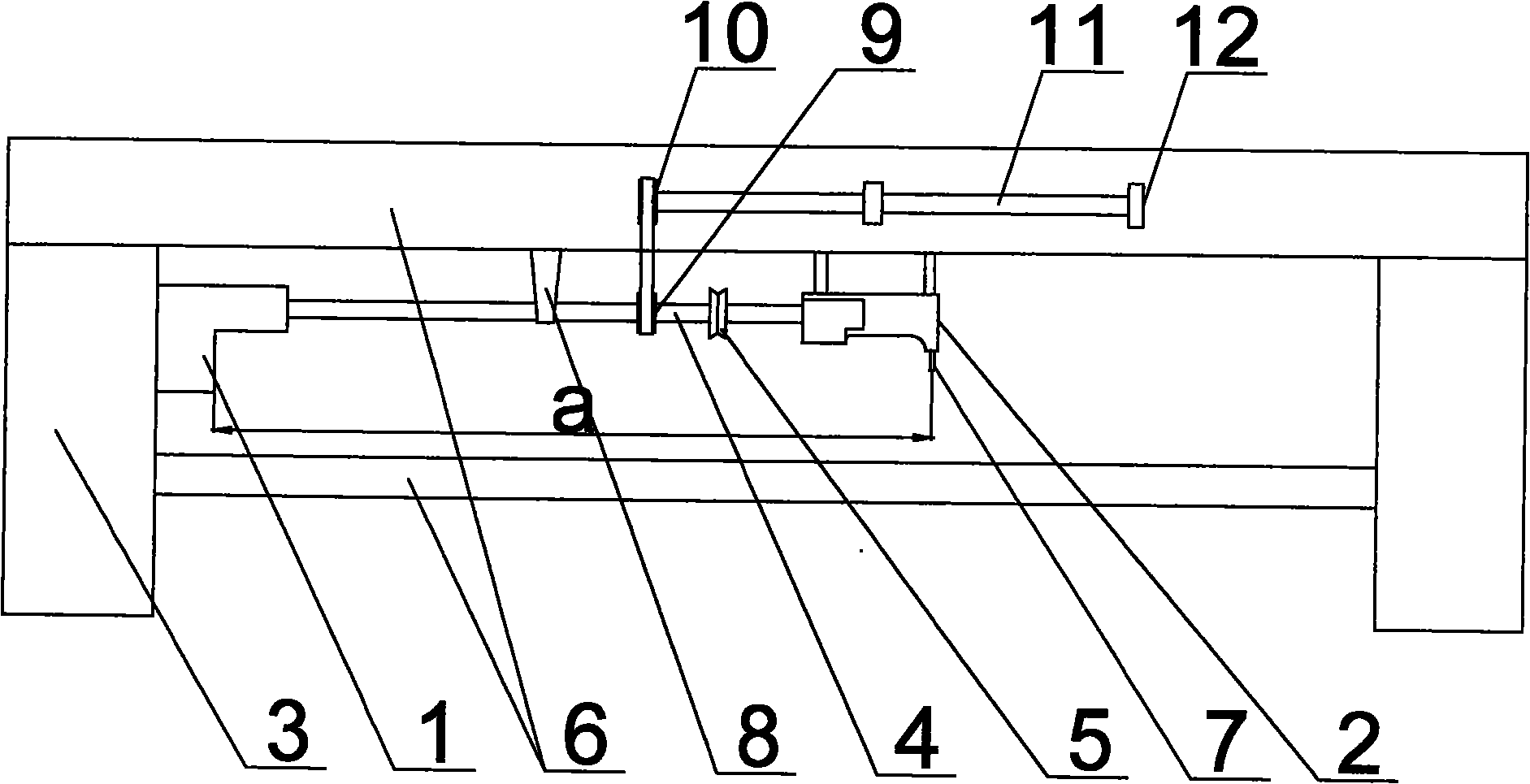

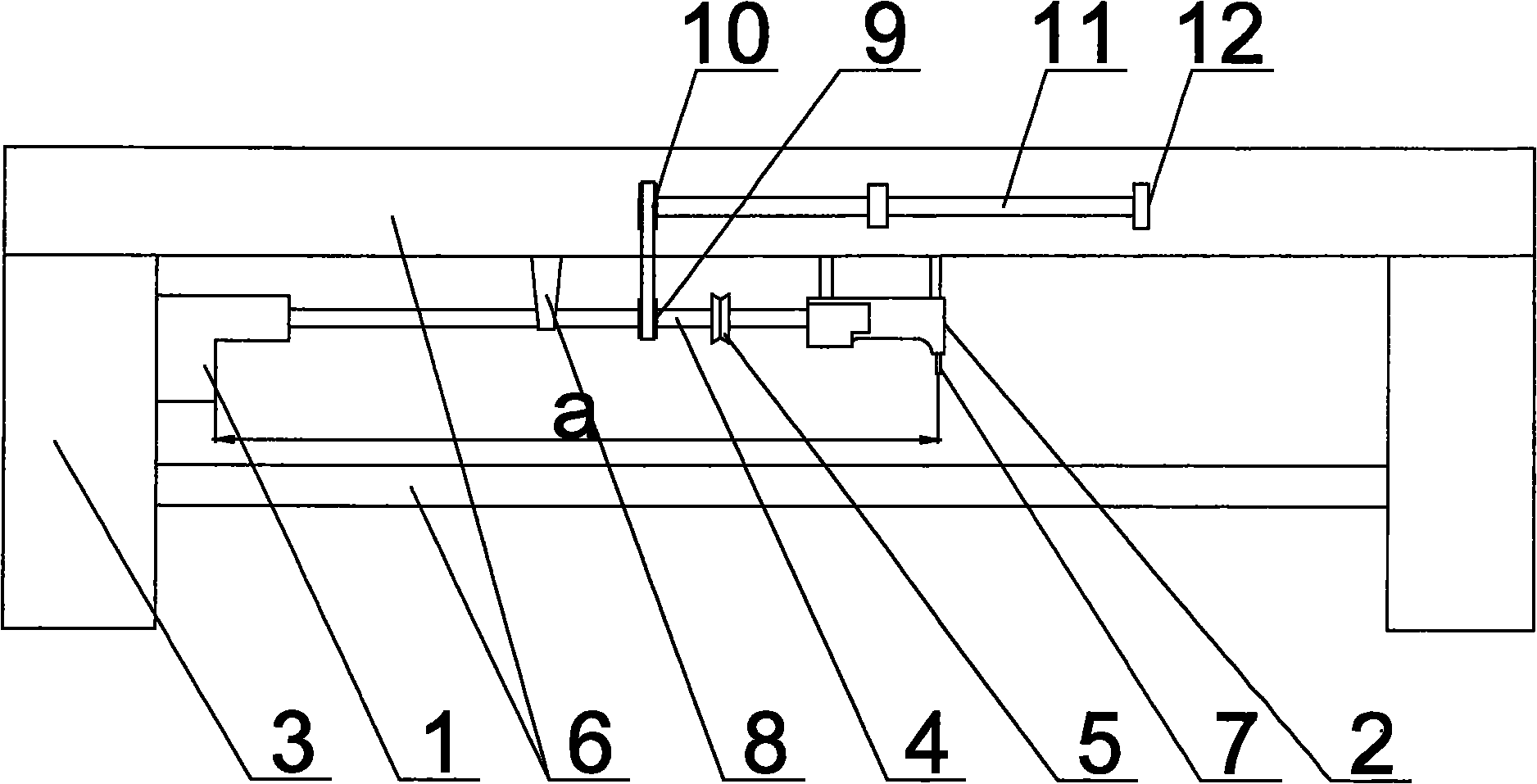

[0016] Embodiments of the invention. Preparation of the mesh surface of the ribbon-type trampoline, including blanking, net weaving, straightening, sewing, correction and other processes. The specific method is:

[0017] (1) According to the working size requirements of different specifications of the mesh surface and the expansion rate of the ribbon under tension, select the appropriate length for cutting, and sew the two ends of the ribbon into a ring shape of 1.0cm-2.0cm, which is used to connect with the mold frame hook connection.

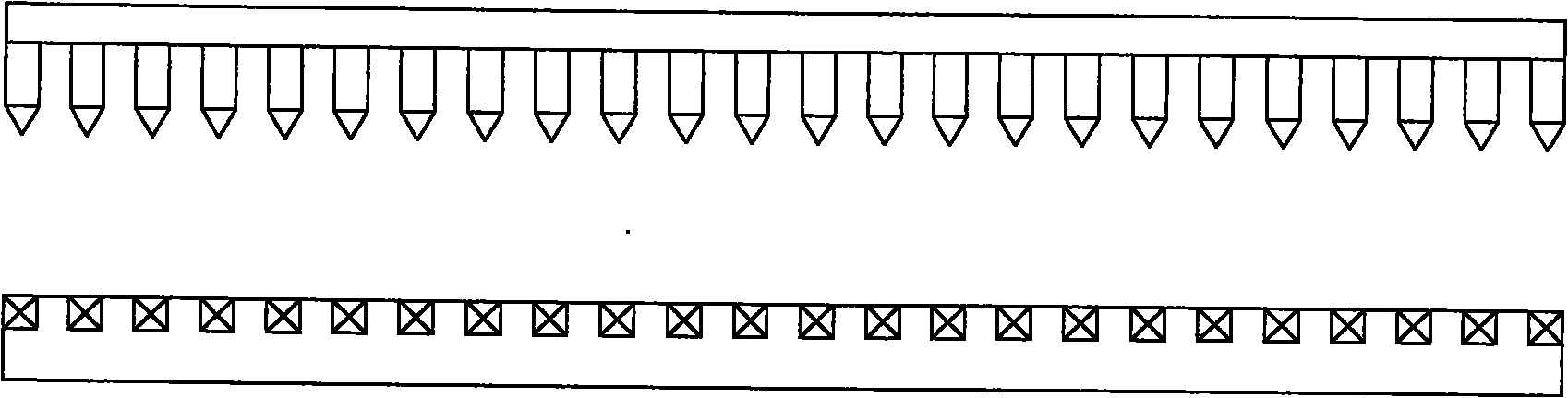

[0018] (2) According to the number of longitudinal and horizontal directions of the webbing, the working size requirements of different specifications of the mesh surface and the stretching rate of the webbing under tension, the mold frame of the netting is prefabricated. The spacing is equal and the size of each square is uniform; the finished product can reach the specified size in the use state; ensure that the mesh woven by the conventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com