Valve rod forging and cold extruding formation process

A forming process and cold extrusion technology, applied in the field of forging process, can solve the problems of unguaranteed product quality, waste of raw materials during working hours, etc., and achieve the effect of good valve sealing effect, less process and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

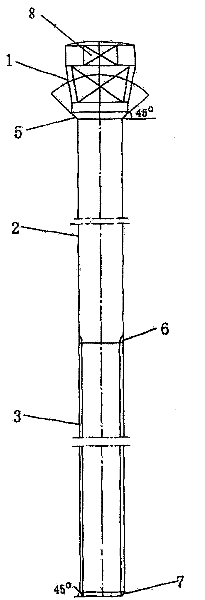

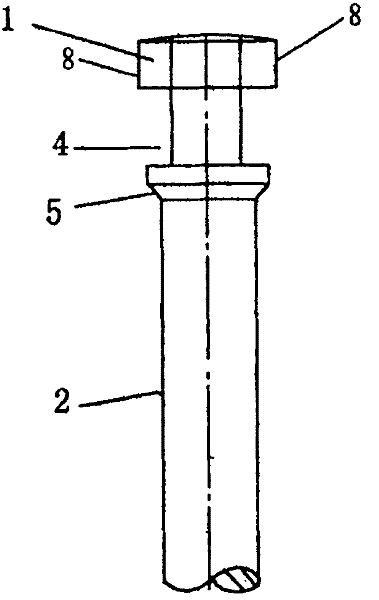

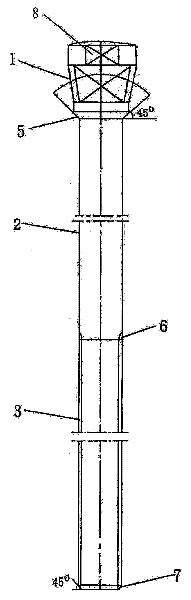

[0035] Such as figure 1 figure 2 As shown, the valve stem is a rod-shaped body, one end of which is a thicker head 1, the left and right sides of the head 1 are provided with trapezoidal grooves 4, the other end of the rod-shaped body is a threaded part 3, and the rod-shaped body The center of the polished rod part 2 is the polished rod part 2. The connection between the head part 1 and the polished rod part 2 is a sealing surface 5 with a 45° chamfer. The end of the part is a 45° chamfer 7 .

[0036] Valve stem forging and cold extrusion molding process of the present invention, its specific technological process is as follows:

[0037] 1. First cut a valve stem bar according to the required size, and then make one end of it soft at a high temperature of 500-600°C, and then directly press the valve stem with a punching force of more than 45 tons in the mold. The head is stamped and formed, including the trapezoidal groove of the head, and a small amount of fine milling pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com