Pressure resistance type soil stress sensor

A stress sensor, piezoresistive technology, which is applied in the field of silicon piezoresistive soil stress sensors, can solve the problems of piezoresistive pressure sensors that have not yet been applied, and achieve the effects of improving measurement accuracy, expanding the force-bearing area, and improving stability characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

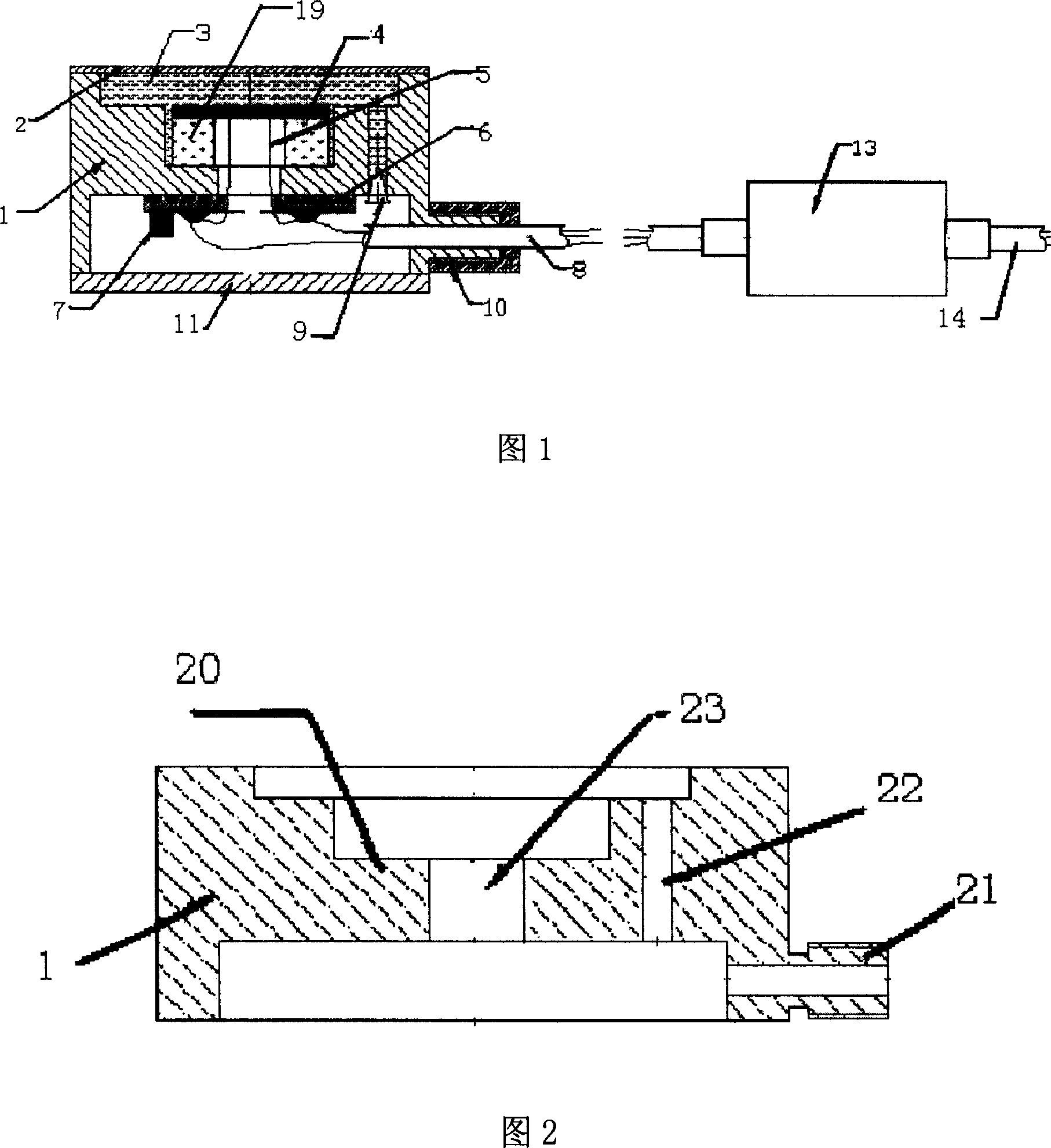

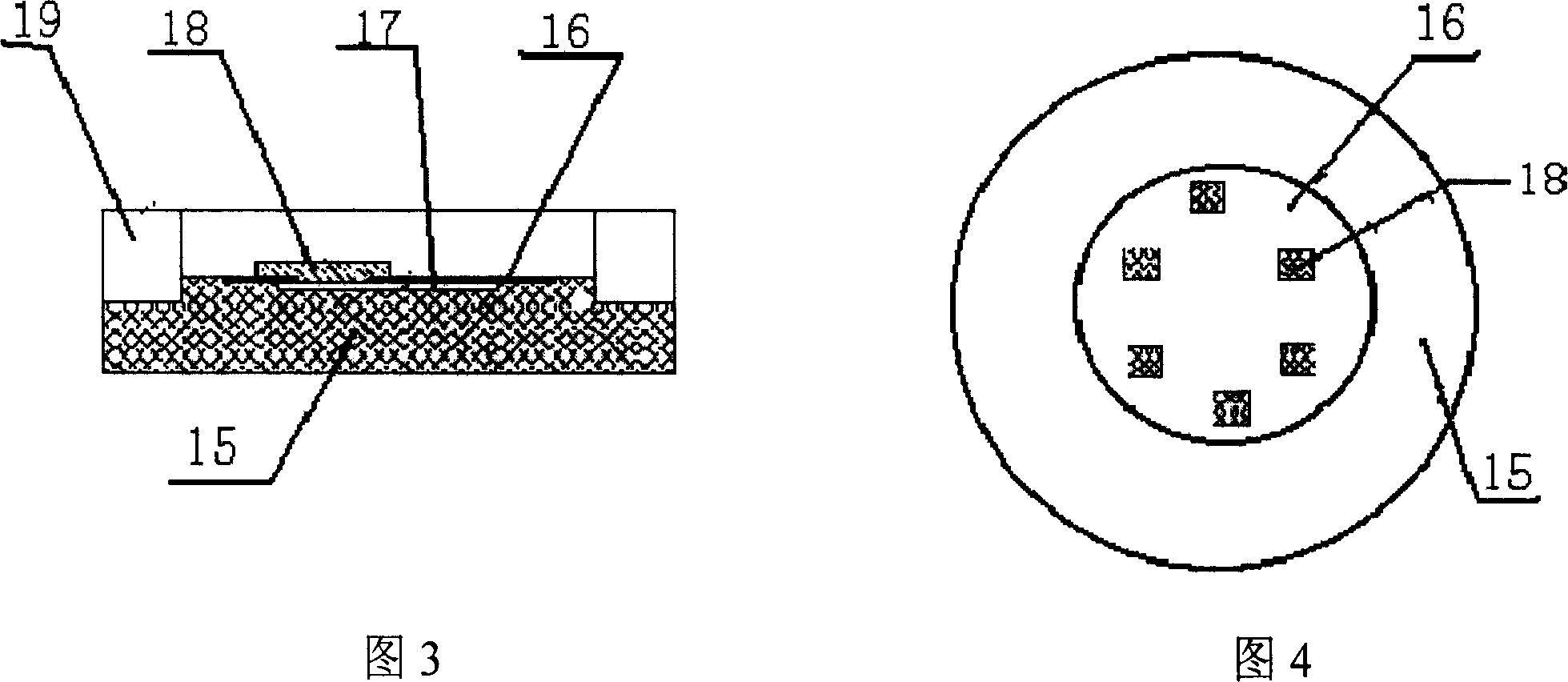

[0035] Further description below in conjunction with accompanying drawing 1 to accompanying drawing 4:

[0036] A piezoresistive soil stress sensor is composed of a sensor housing 1, a stress-sensitive component 4 and an output cable 14. The front end of the sensor housing is welded with an elastic body 2 of a flat-film metal that can sense stress. Inside the sensor housing is formed a A fixed support step 20 with a hole 23 structure, the sensitive component is a silicon piezoresistive component, and is fixed on the end surface of the fixed support step, and the cavity formed between the elastic body 2 is filled with a grade A silicone oil pressure transmission medium 3, the The inner lead wire 5 of the sensitive component is externally connected to the outgoing cable 8 through the adapter plate 6 fixed at the rear end of the sensor housing, and the outgoing cable is externally connected to the output cable after passing through the signal conditioning circuit 13 .

[0037] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com