Pollutant removing process and pollutant removing agent for radioactive pollution metal

A decontamination agent and metal technology, applied in radioactive purification, nuclear engineering, etc., to achieve high decontamination coefficient, reduce pretreatment cost, and fast decontamination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

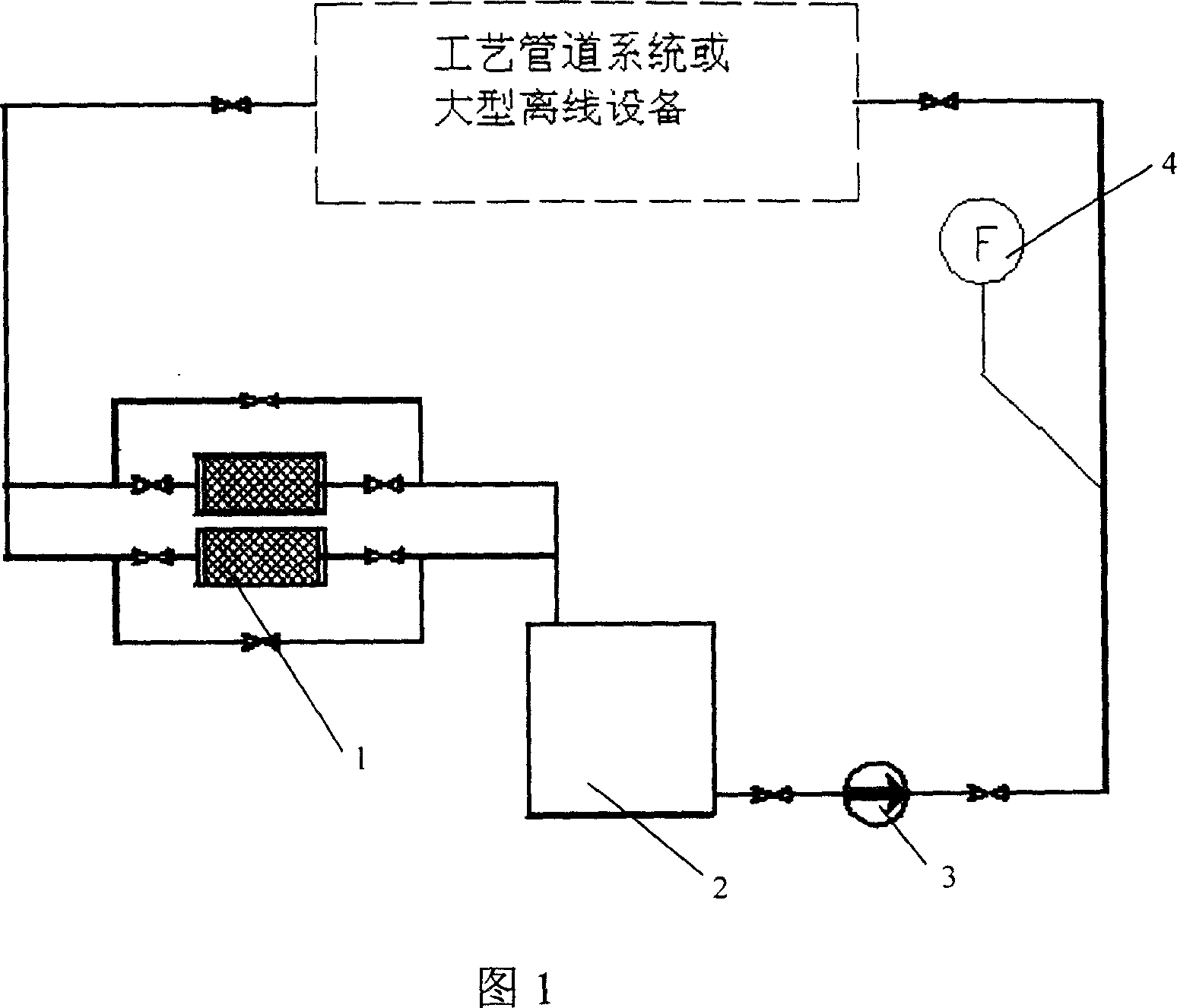

[0013] The loop circulation method is used to decontaminate radioactively contaminated metals, followed by rinsing and drying. The loop circulation method is a well-known decontamination method, which specifically refers to the need to establish a Decontaminant injection (circulation) systems that allow decontamination to flow through process piping systems or the interior of large off-line equipment to decontaminate them. Its process flow is shown in Figure 1.

[0014] The decontamination process steps are as follows:

[0015] (1) Radioactive contamination level measurement or radioactive analysis before decontamination.

[0016] (2) Detergent preparation: using industrial (NH 4 ) 2 Ce(NO 3 ) 6 ·6H 2 O, industrial nitric acid and deionized water preparation nitric acid concentration is 0.1~6.0mol / L, Ce (IV) concentration is the detergent of 0.001~1.00mol / L. The specific concentration of Ce(IV) depends on the degree of decontamination required. If the degree of radioac...

Embodiment 2

[0023] Decontamination of radioactively contaminated metals is carried out by bath immersion method, followed by rinsing and drying. The tank soaking method is a well-known decontamination method. Specifically, when decontaminating off-line small parts, pipe fittings, and radioactively contaminated metal parts after disassembly and disassembly, a decontamination tank needs to be established, and the parts to be decontaminated are directly decontaminated. Soak in the detergent in the decontamination tank for soaking and decontamination.

[0024] The decontamination process steps are as follows:

[0025] (1) Radioactive contamination level measurement or radioactive analysis before decontamination.

[0026] (2) Detergent preparation: using industrial (NH 4 ) 2 Ce(NO 3 ) 6 ·6H 2 O, industrial nitric acid and deionized water preparation nitric acid concentration is 0.1~6.0mol / L, Ce (IV) concentration is the detergent of 0.001~1.00mol / L. The specific concentration of Ce(IV) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com