Magnesium diboride super conductive material and its preparing method

A technology of magnesium diboride and superconducting materials, which is applied in the field of preparation of superconducting materials, can solve problems affecting the practical progress of magnesium diboride superconductors, and achieve critical current density improvement, grain refinement, and magnetic flux nailing. The effect of improving the tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

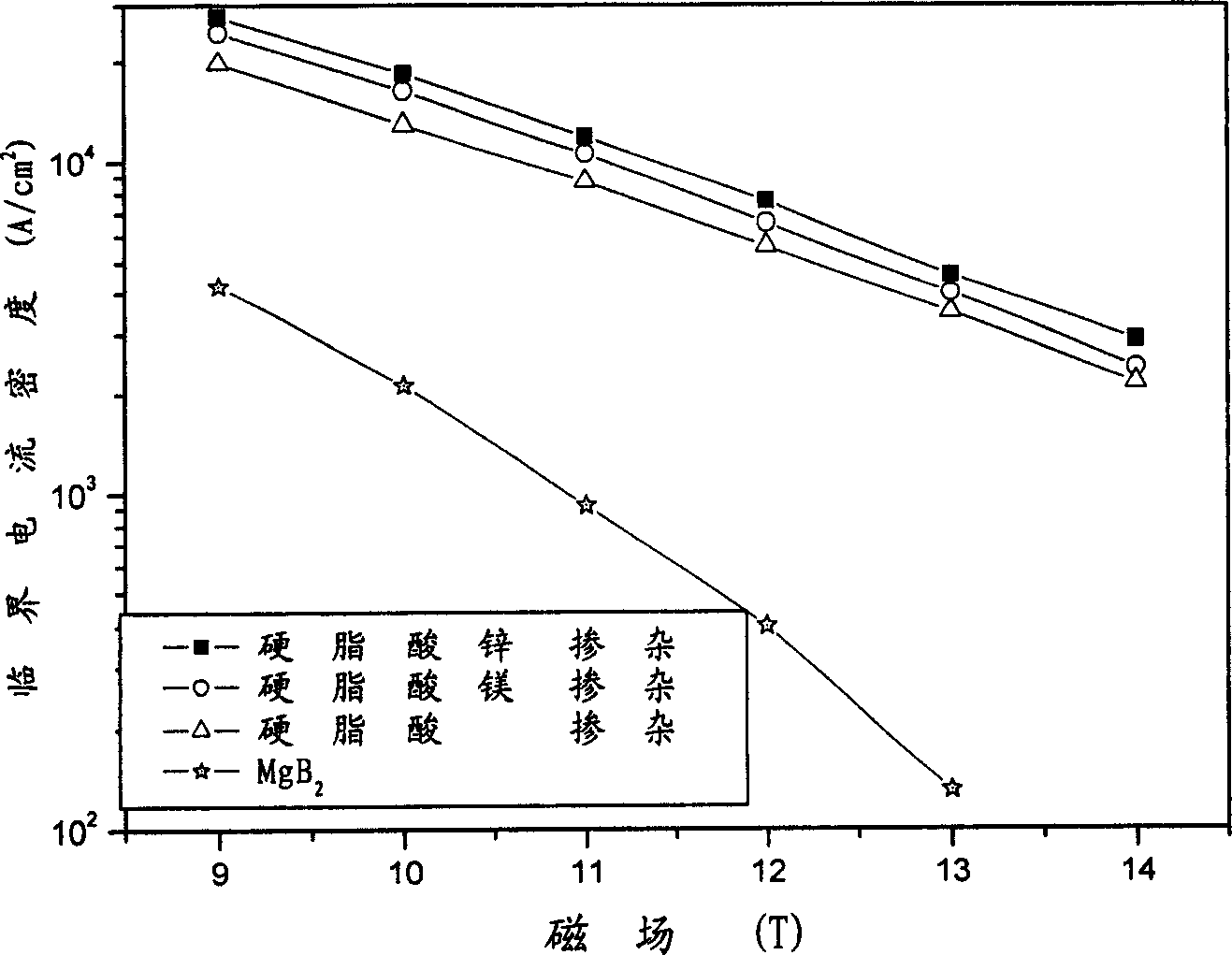

[0023] Preparation of magnesium diboride strips doped with stearic acid. The ratio of the mass sum of Mg powder (325 mesh, purity not less than 99%) and B powder (amorphous, purity 99.99%) to the mass of stearic acid powder is: MgBy: X=1: 0.111, wherein Mg powder and The molar ratio of B powder component Mg:B=1:2, ie y=2. Dissolve stearic acid powder in alcohol first, then ultrasonically mix the solution with B powder in the above ratio, dry in vacuum, then mix with Mg powder in the above ratio with a mortar, mix evenly, and pack into an iron pipe, swaged, drawn, and rolled to a strip of 0.5mm×4.0mm, sintered and heat-treated in an argon atmosphere at normal pressure, and kept at 800°C for 1 hour to prepare stearic acid-doped bismuth Magnesium boride strip. The critical current density of this magnesium diboride strip can reach 13000A / cm at 4.2K, 10T 2 ; At 14T, the critical current density can reach 2160A / cm 2 .

Embodiment 2

[0025] Preparation of magnesium diboride strips doped with zinc stearate. The ratio of the mass sum of Mg powder (325 mesh, purity not less than 99%) and B powder (amorphous, purity 92%) to the mass of zinc stearate powder is: MgBy:X=1:0.1, wherein Mg powder The molar ratio Mg:B=1:1.9 with B powder component, namely y=1.9. First dissolve the zinc stearate powder in acetone, then ultrasonically mix the solution with the B powder in the above ratio, dry it in vacuum, and then mix it with the Mg powder in the above ratio with a mortar. After mixing evenly, Put it into an iron pipe, swage, draw, and roll to a strip of 0.5mm×4.0mm, carry out sintering heat treatment in an argon atmosphere at normal pressure, and keep it at 850°C for 0.5 hours to prepare a strip containing doped zinc stearate Magnesium diboride strip. The critical current density of this magnesium diboride strip can reach 20000A / cm at 4.2K, 10T 2 ; At 14T, the critical current density can reach 3100A / cm 2 .

Embodiment 3

[0027] Magnesium diboride strips doped with magnesium stearate were prepared. The ratio of the mass sum of Mg powder (325 mesh, purity not less than 99%) and B powder (amorphous, purity 98%) to the mass of magnesium stearate powder is: MgBy: X=1: 0.08, wherein Mg and The molar ratio of B component Mg:B=1:2.1, ie y=2.1. Dissolve the magnesium stearate powder in acetone first, then mix the solution with the B powder in the above ratio through ultrasonic mixing, dry it in vacuum, and then mix it with the Mg powder in the above ratio by using a mortar. After mixing evenly, put it into an iron pipe, swage, draw, and roll to a strip of 0.5mm×4.0mm, sinter heat treatment in an atmosphere of argon at normal pressure, and keep it at 900°C for 0.1 hour to prepare a strip containing dopant. Magnesium diboride strip of magnesium stearate. The critical current density of this magnesium diboride strip can reach 2600A / cm at 4.2K, 14T 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Critical current density | aaaaa | aaaaa |

| Critical current density | aaaaa | aaaaa |

| Critical current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com