Multi-pulse ignition circuit for a gas discharge lamp

A technology of gas discharge lamp and ignition circuit, which is applied in the field of ignition circuit and can solve problems such as long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

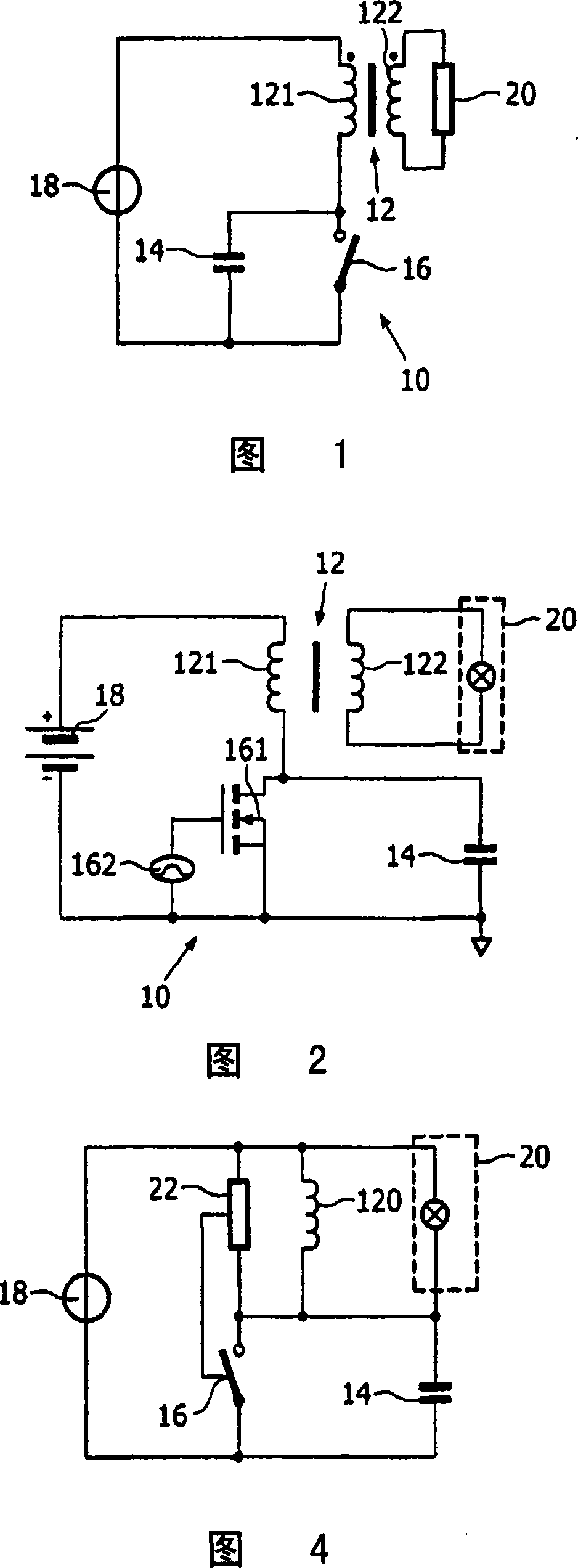

[0026] FIG. 1 shows an ignition circuit 10 comprising a primary winding 121 of a transformer 12 , capacitor 14 and switch 16 . The ignition circuit 10 is coupled to a voltage supply 18 . The secondary winding of the transformer is coupled to a gas discharge lamp circuit 20 . The gas discharge lamp circuit 20 includes a gas discharge lamp and possibly one or more other components.

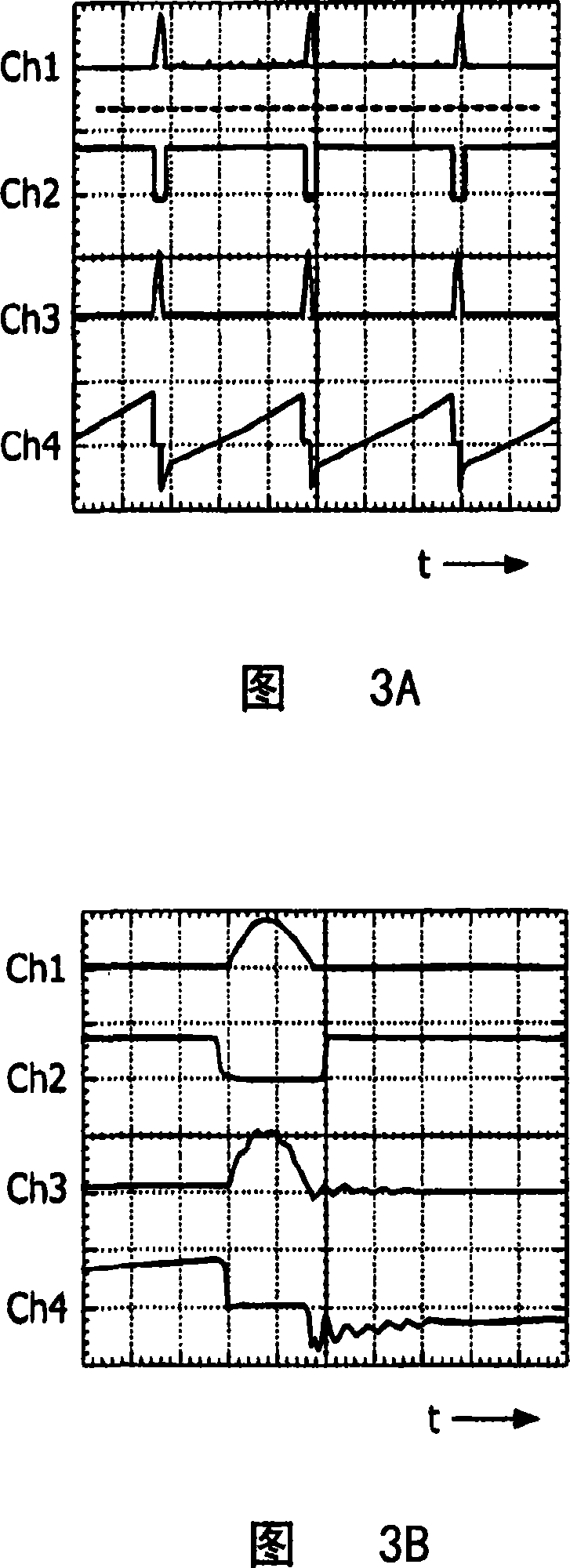

[0027] In the exemplary embodiment shown in FIG. 2 , the switch is specifically a transistor 161 and a switch driving circuit 162 . The transistor 161 is a MOSFET transistor with a body diode. From the following description of the operation of the ignition circuit 10, it will be apparent to those of ordinary skill in the art that any circuit or component suitable for switching current at high frequencies may incorporate the switch. Next, the operation of the ignition circuit according to the present invention will be explained with reference to FIG. 2, FIGS. 3A and 3B.

[0028] In FIGS. 3A and 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com