Hollow build cover of cast-in-situ reinforcing steel bar concrete

A hollow floor and reinforced concrete technology, which is applied to floors, building components, buildings, etc., can solve problems affecting the overall quality and mechanical performance of cast-in-place concrete hollow floors, inconsistent thickness of the outer concrete protective layer, cast-in-place concrete ribs Inconsistent width and other problems, to achieve the effect of satisfying force performance, reducing construction cost, and convenient layout and connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

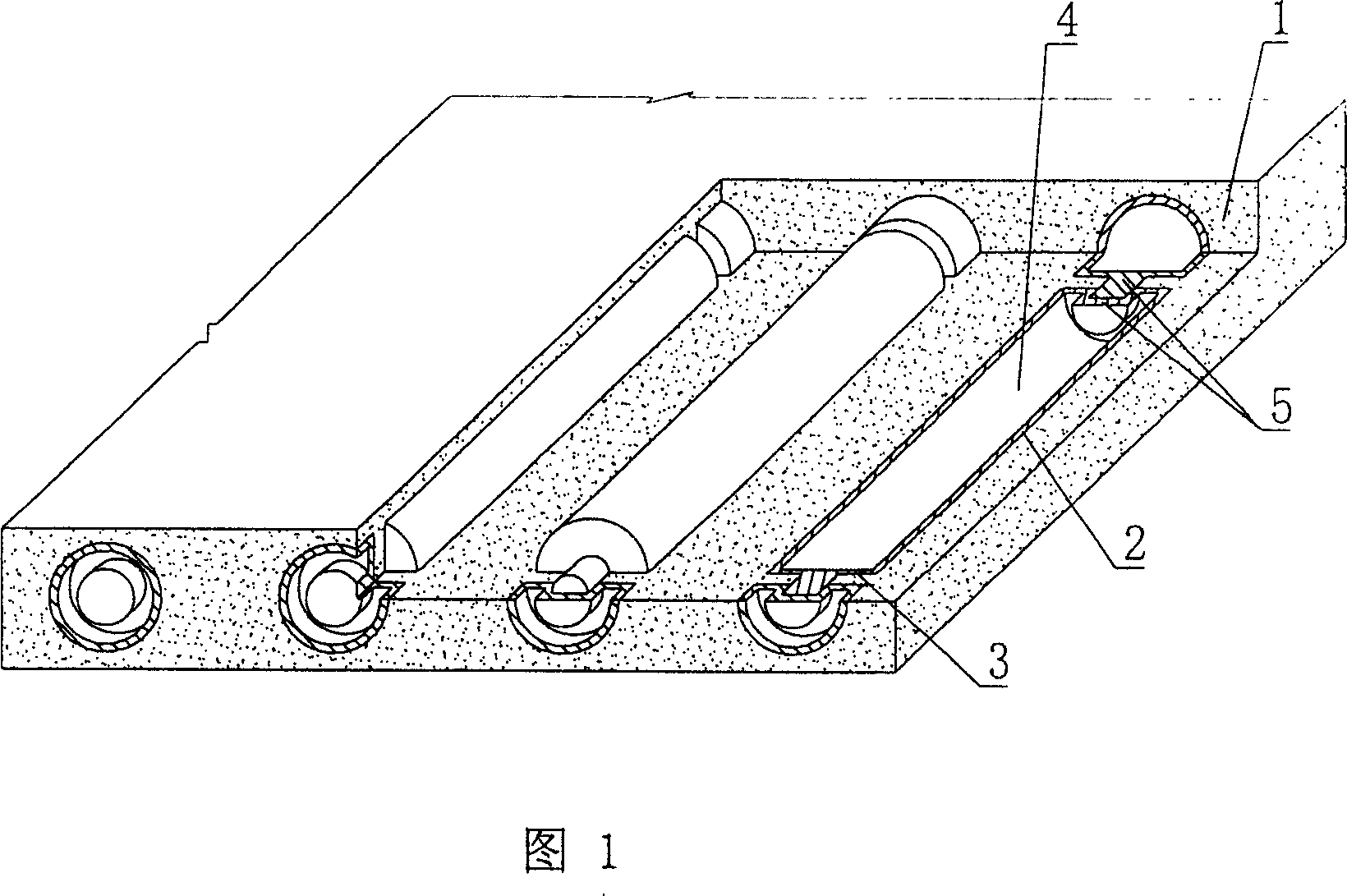

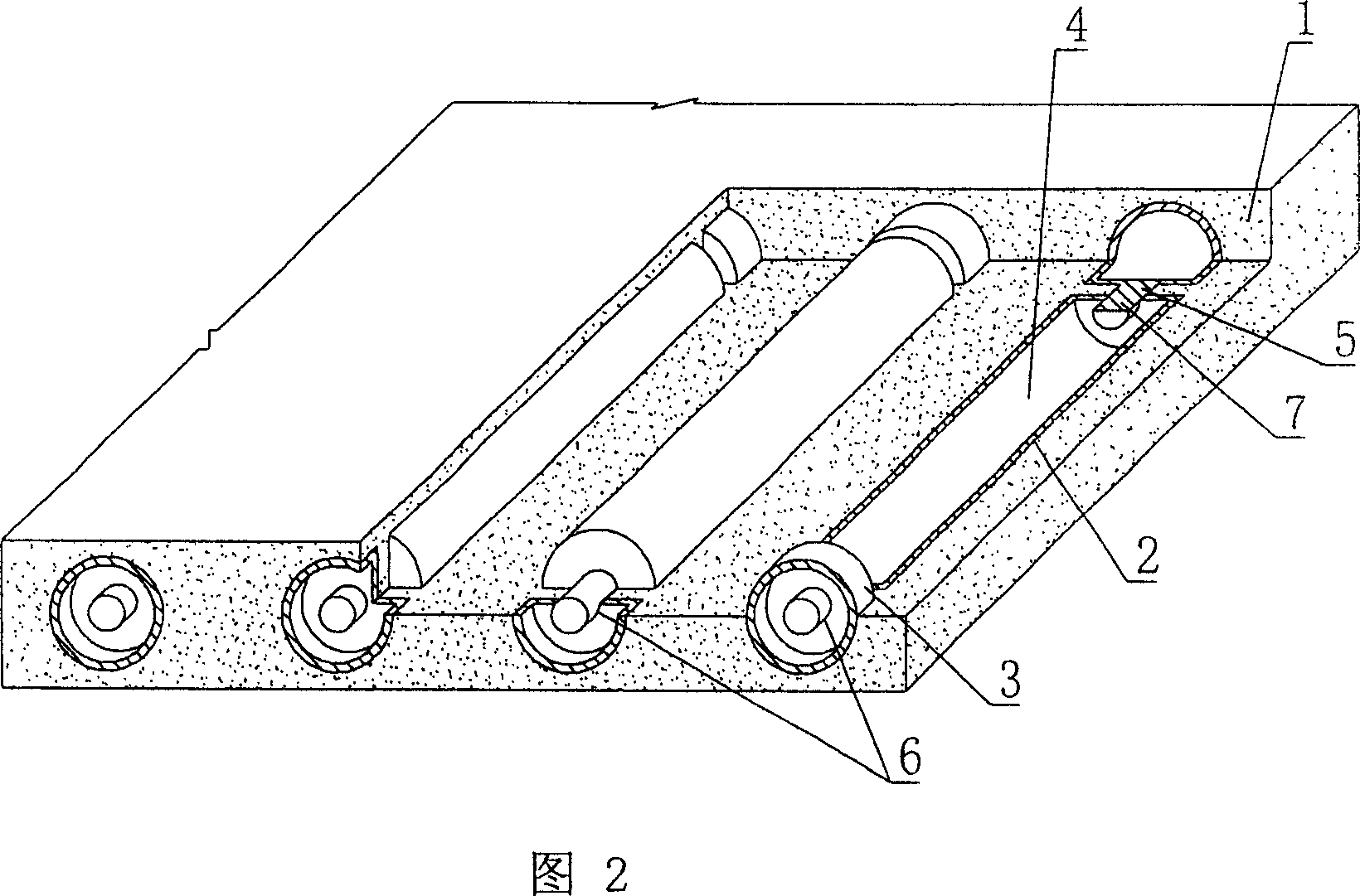

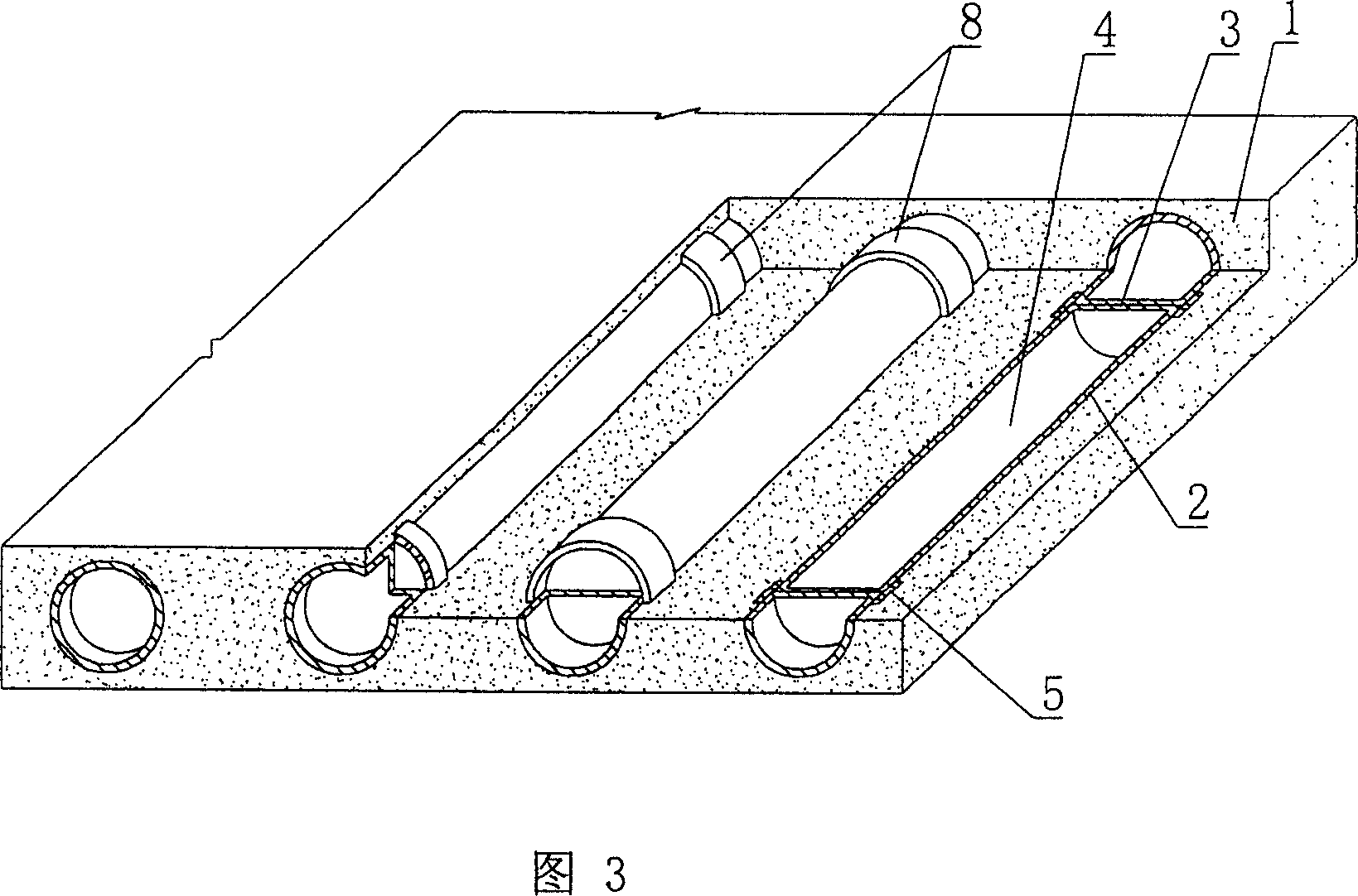

[0027] As shown in the accompanying drawings, the present invention includes reinforced concrete 1 and hollow pipe 2. The hollow pipe 2 is embedded in the reinforced concrete 1. The sealing plugs 3 at both ends of the hollow pipe 2 seal the hollow pipe 2 to form a closed cavity 4. It is characterized in that the sealing plug 3 at least one end of the hollow tube 2 is provided with a docking device 5 for connection and positioning between the hollow tubes 2, and the hollow tube 2 is filled with a tubular light material. Fig. 1 is a schematic structural diagram of Embodiment 1 of the present invention. In each accompanying drawing, 1 is reinforced concrete, 2 is a hollow pipe, 3 is a plug at both ends of the hollow pipe 2, 4 is a closed cavity in the hollow pipe 2, and 5 is a hollow pipe provided on the sealing plug 3 of the hollow pipe 2. The docking de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com