Mould climbing platform system and mould climbing method thereof

A platform and climbing formwork technology, applied in the field of construction equipment systems, can solve problems such as undisclosed scaffolding lifting devices, and achieve the effects of reducing labor costs and time costs, reducing labor intensity, and improving construction quality and construction safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

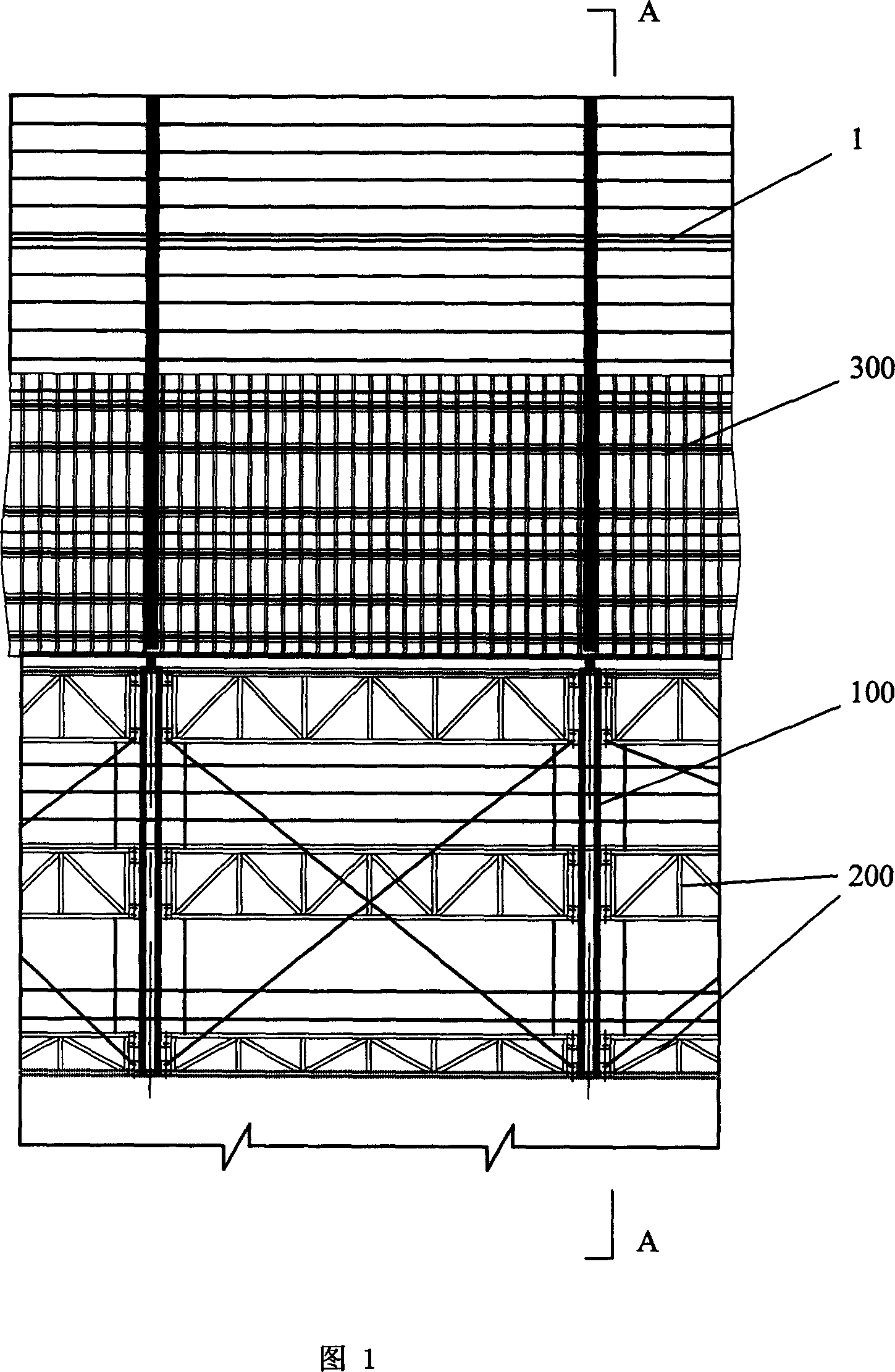

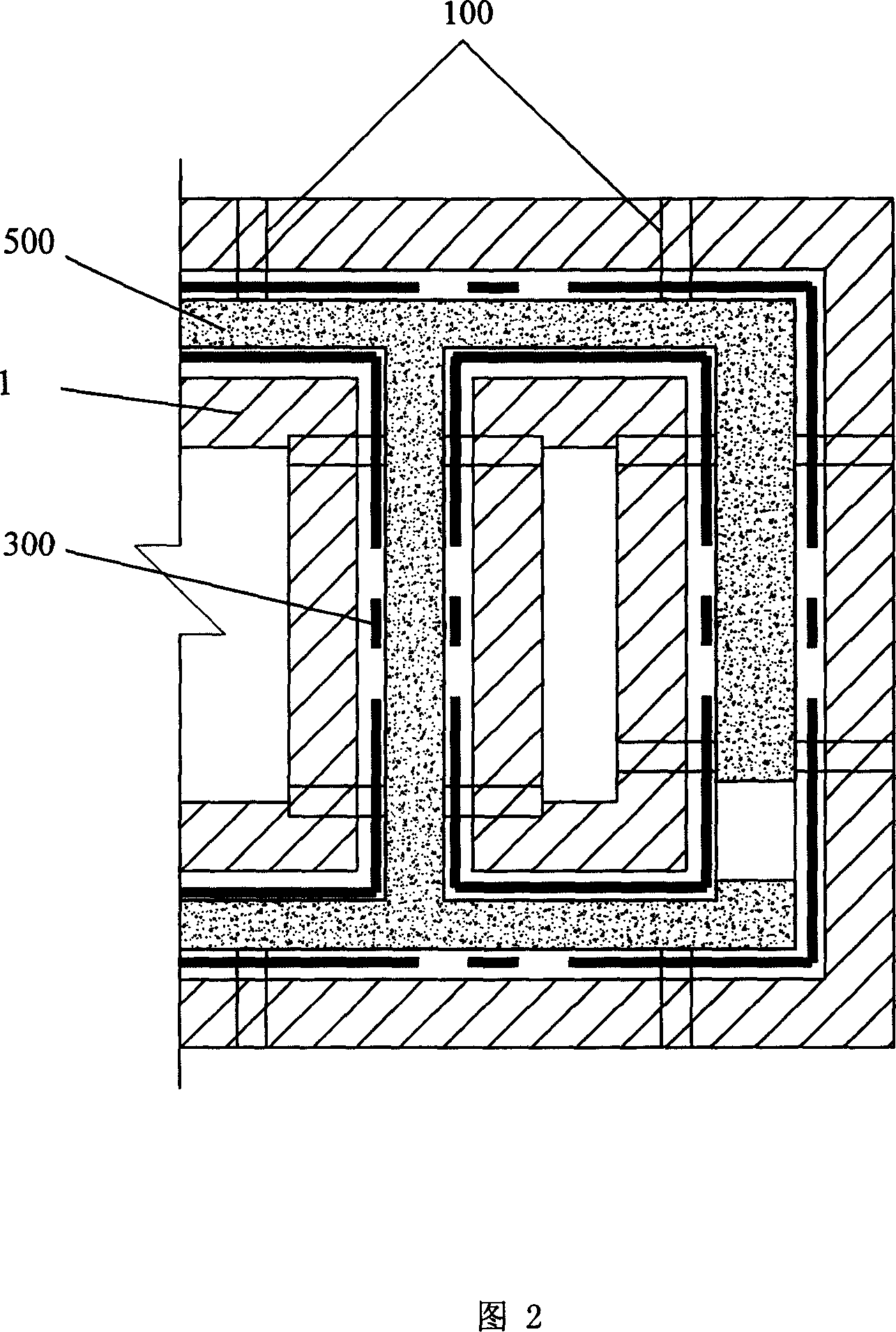

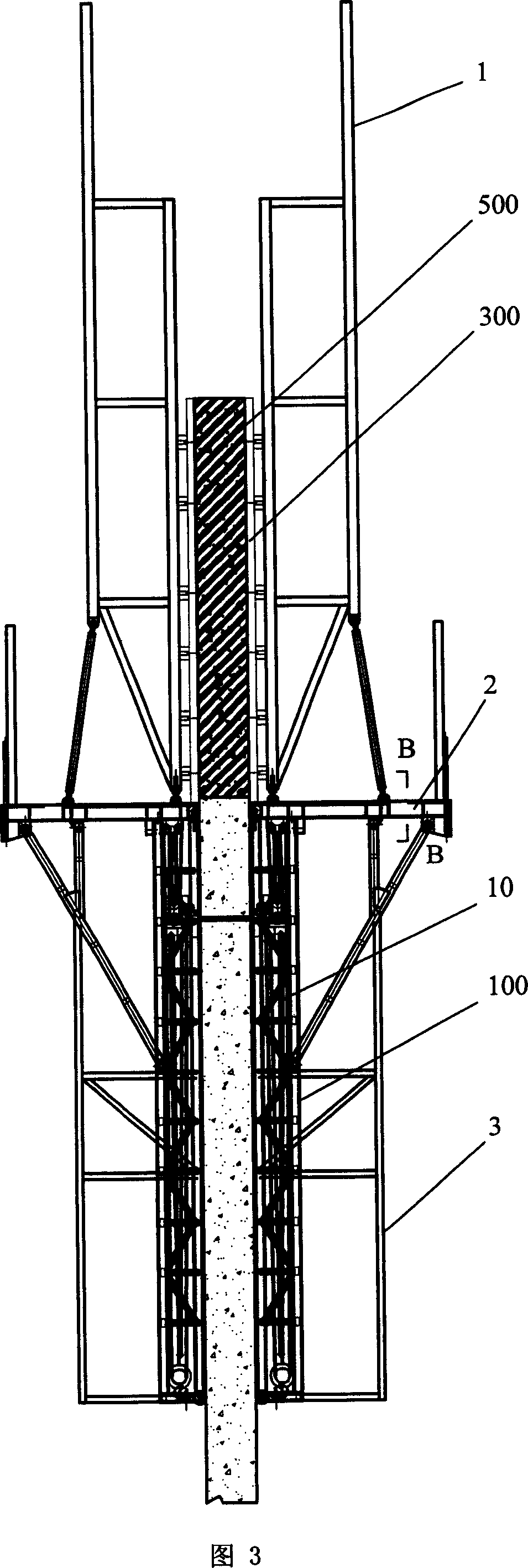

[0047] Fig. 1 and Fig. 2 show the elevation view and plan view of the climbing formwork platform system of the present invention, and Fig. 3 shows the cross-sectional view of the climbing formwork platform system of the present invention. As shown in Figures 1, 2, and 3, the climbing formwork platform system includes an operating platform connected as a whole in space and positioned at one side of the building structure 500, a lifting guide rail 100 fixedly connected with the operating platform, and a building guide 105 (as shown in FIG. 7), temporary fixtures (not shown), template 300 and lifting device 10, the detailed structure is as follows:

[0048] The building guide 105 can be fixed on the building structure 500 through a rod inserted horizontally in the wall, a bolt or a pair of tie rods of the wall formwork, or a nail fixed on the wall, a hook, etc.; the building structure 500 can be Walls, floors, columns or beams, etc.

[0049] As shown in Figure 3, the operating p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com