Ring conveying system of calcium carbide furnace

A conveying system, calcium carbide furnace technology, applied in furnaces, furnace components, electric charge control, etc., can solve problems such as difficult repair and maintenance, low operating efficiency, increased safety hazards, etc., to save cooling workshops, facilitate maintenance, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

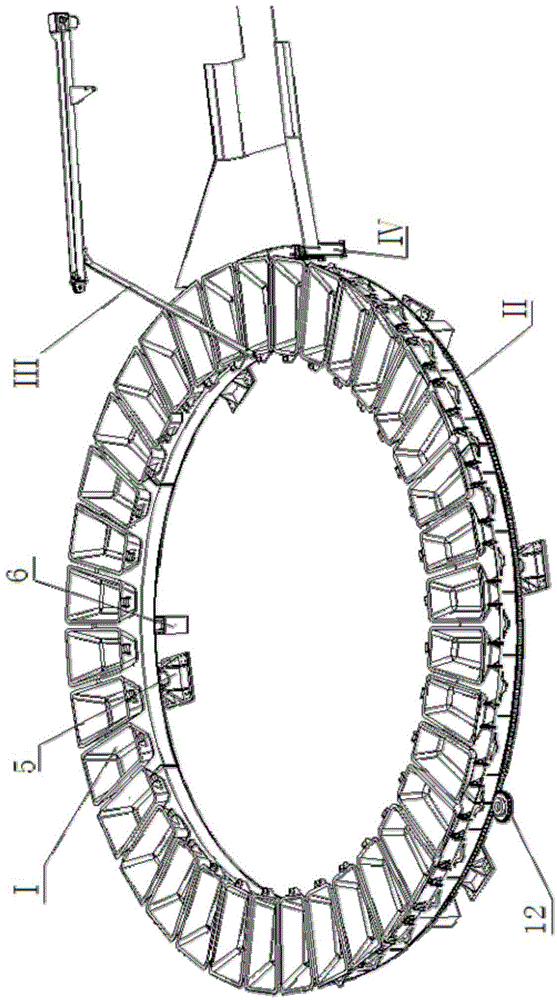

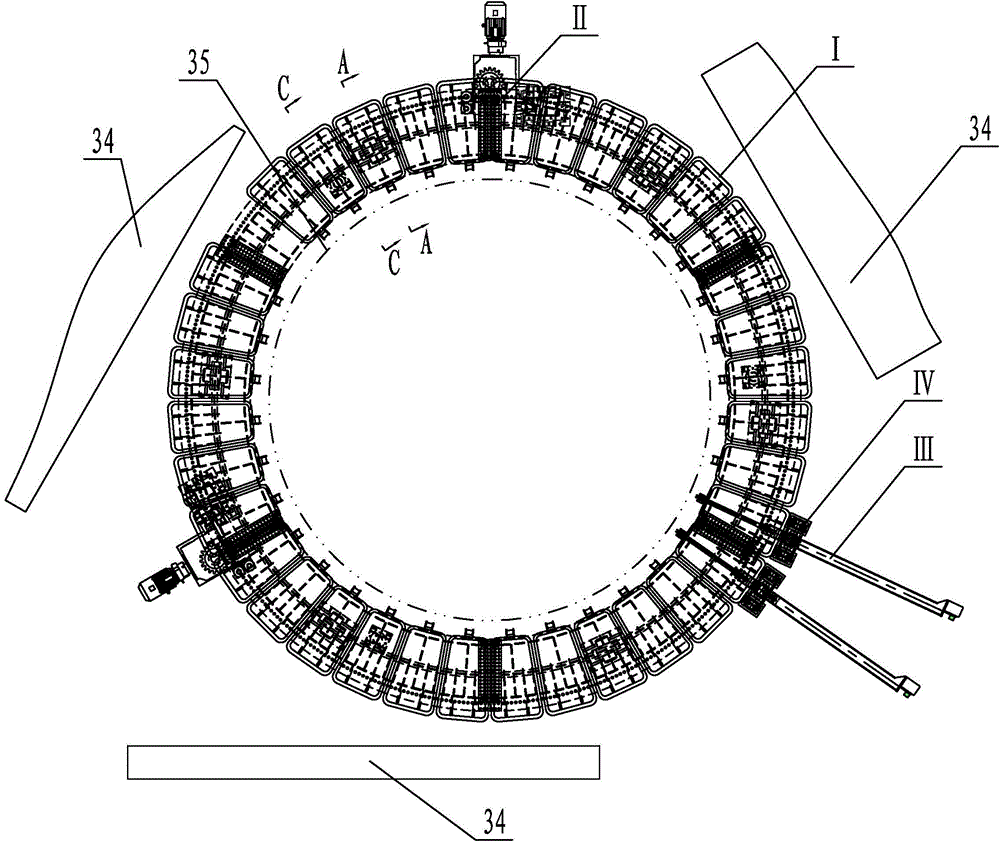

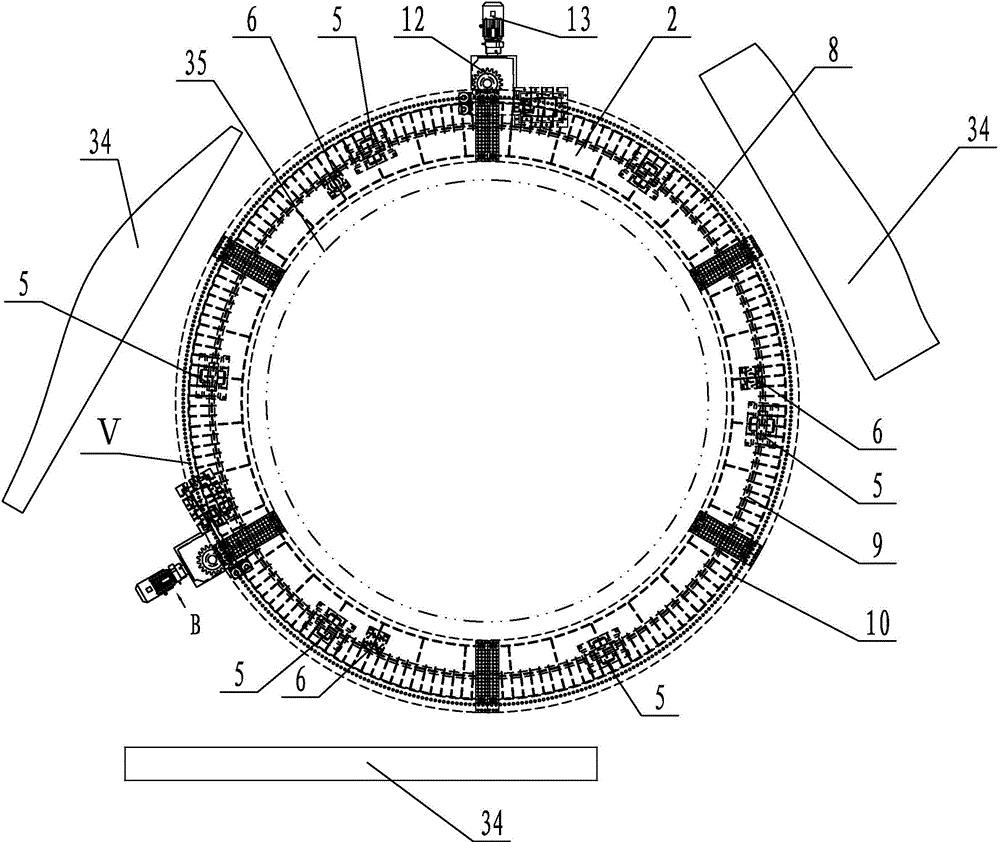

[0028] The content of the present invention will be described in detail below in conjunction with the accompanying drawings: The calcium carbide furnace circular conveying system of the present invention is composed of calcium carbide pot I, disc drive system II, tipping mechanism III, and vibration unloading device IV. There are 36 calcium carbide pots I around the furnace body 35 of the calcium carbide furnace, and the calcium carbide pots I are connected to the disk 2 through the pin shaft i-1. The disc 2 is arranged concentrically with the calcium carbide furnace and surrounds the outside of the furnace body. Tilting mechanism III is arranged between two burn-through platforms 34, on the outside of disk drive system II. There are two sets of tilting mechanism III, arranged radially, with the center line pointing to the center of the circle. The vibrating unloading device IV is arranged outside the disc drive system II, just below the tilting mechanism III, and when the cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com