Planetary gear apparatus

A technology of planetary gears and sun gears, which is applied in the field of improvement of planetary gear carriers, can solve the problems of reduced gear durability, improper meshing of gears, gear noise, etc., and achieves the effect of increasing torsional rigidity and reducing processing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

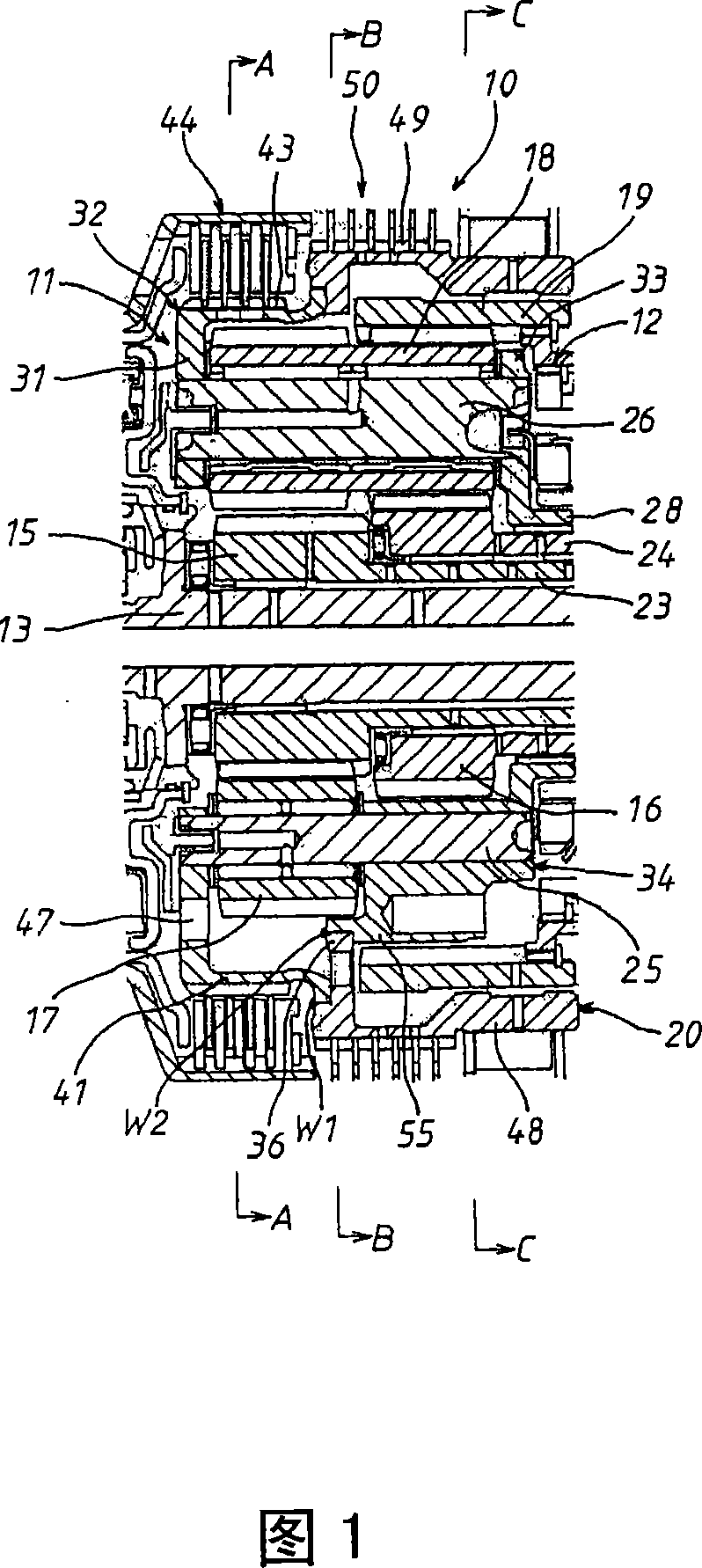

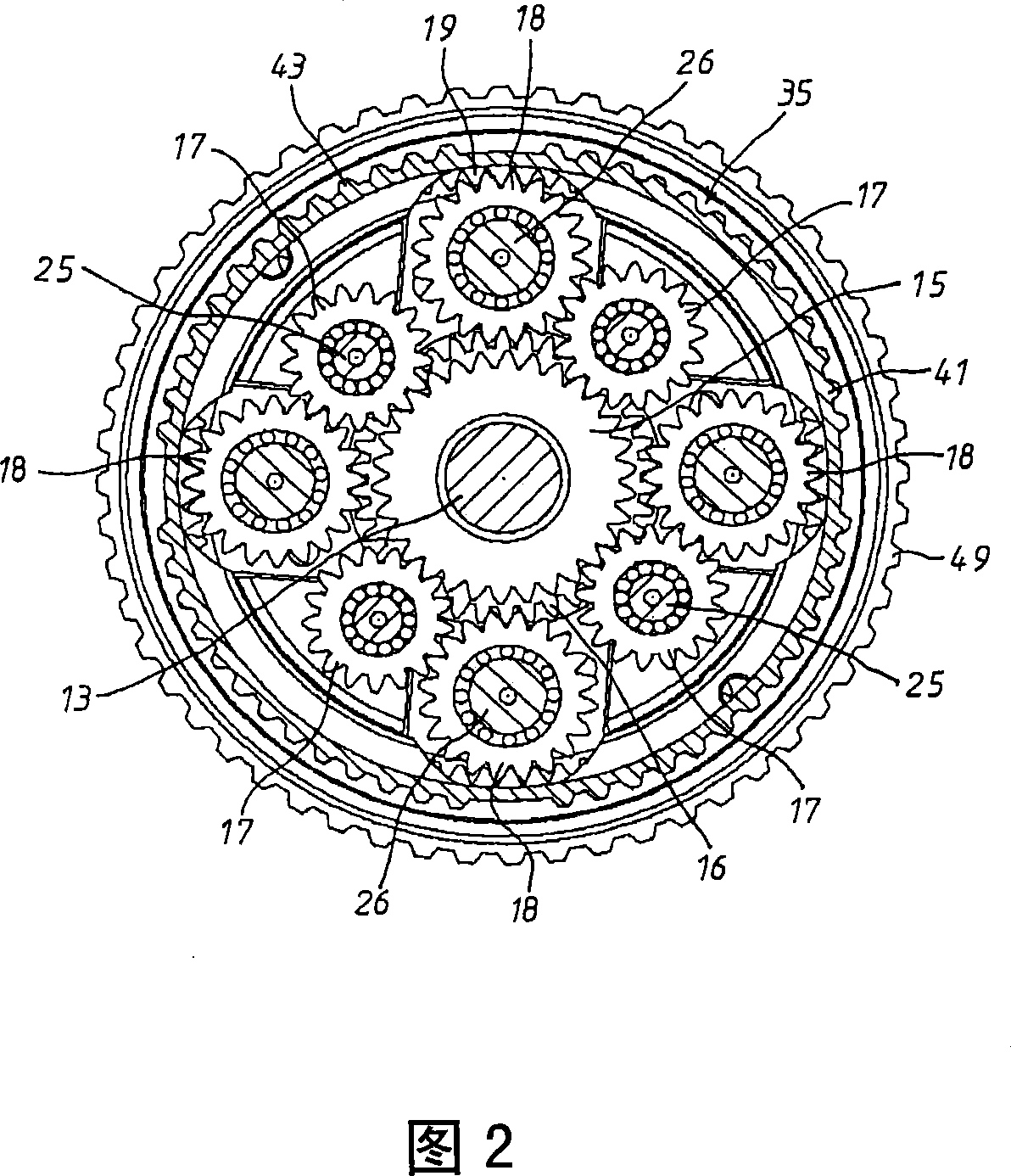

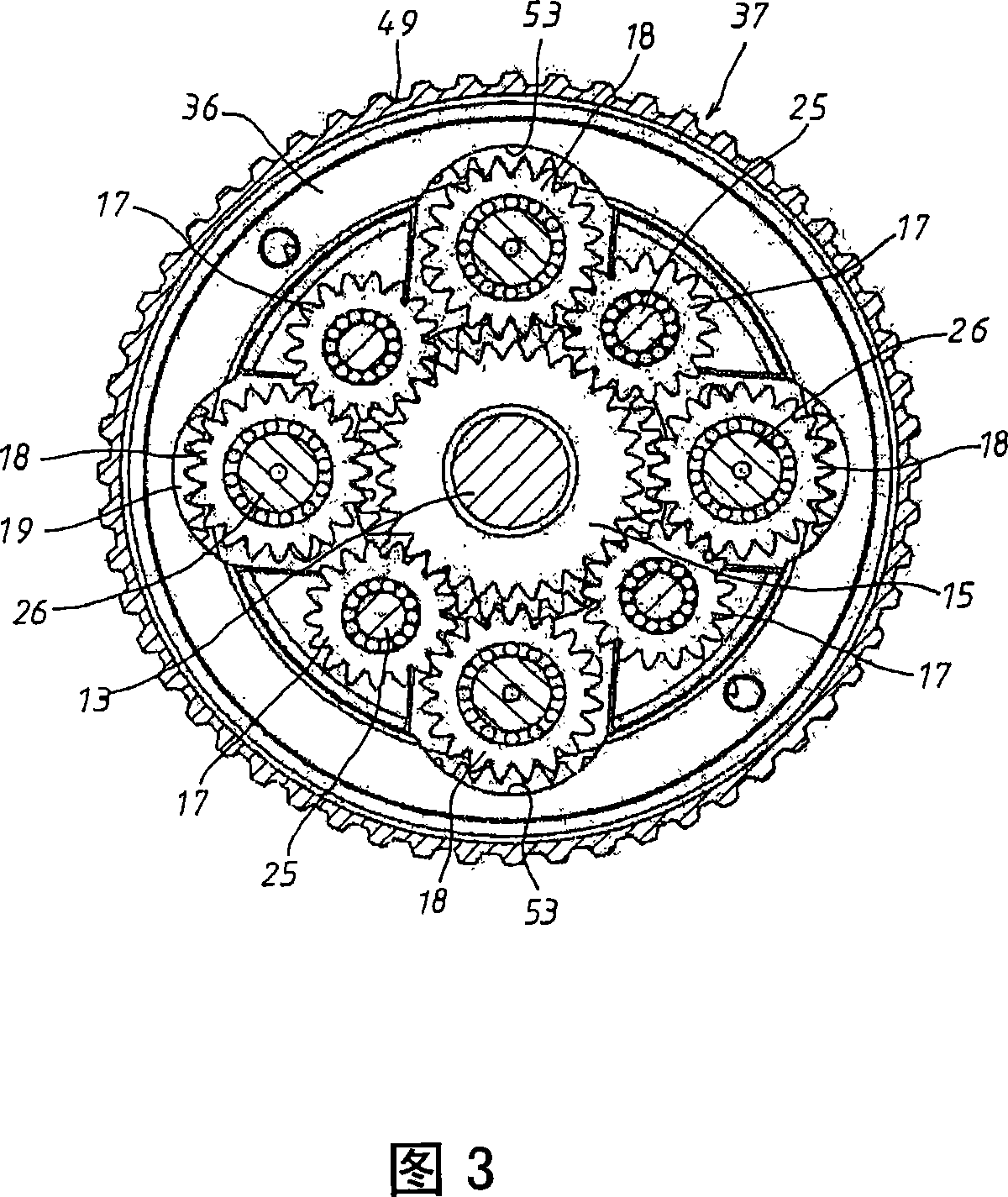

[0028] Hereinafter, a first embodiment of the present invention will be described with reference to the drawings. Fig. 1 shows the whole of the double-gear type planetary gear device 10 after the first and second two sets of planetary gears 11, 12 are combined, and Fig. 2, Fig. 3 and Fig. 4 represent lines A-A, B-B and C-C of Fig. 1 Sectional view of each part cut separately. The planetary gear unit 10 mainly includes: an input shaft 13 rotatably supported on a housing not shown in the figure; first and second sun gears 15 and 16 respectively supported on the input shaft 13 so as to be relatively rotatable; A plurality of narrow gears 17 on the circumference engaged with a sun gear 15; a plurality of wide gears 18 engaged on the circumference with these narrow gears 17 and the second sun gear 16; a ring gear 19 engaged with the wide gear 18; Said narrow gear 17 and wide gear 18 and ensure that it can rotate the planetary gear carrier 20.

[0029] The input shaft 13 is driven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com