Lamp having improved vibration damping

A lamp base and lamp holder technology, applied in the field of vehicle lamps, can solve problems such as broken working life, shortened lamp life, and unfavorable lamp life, and achieve the effects of good damping, increased life, and reduced possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

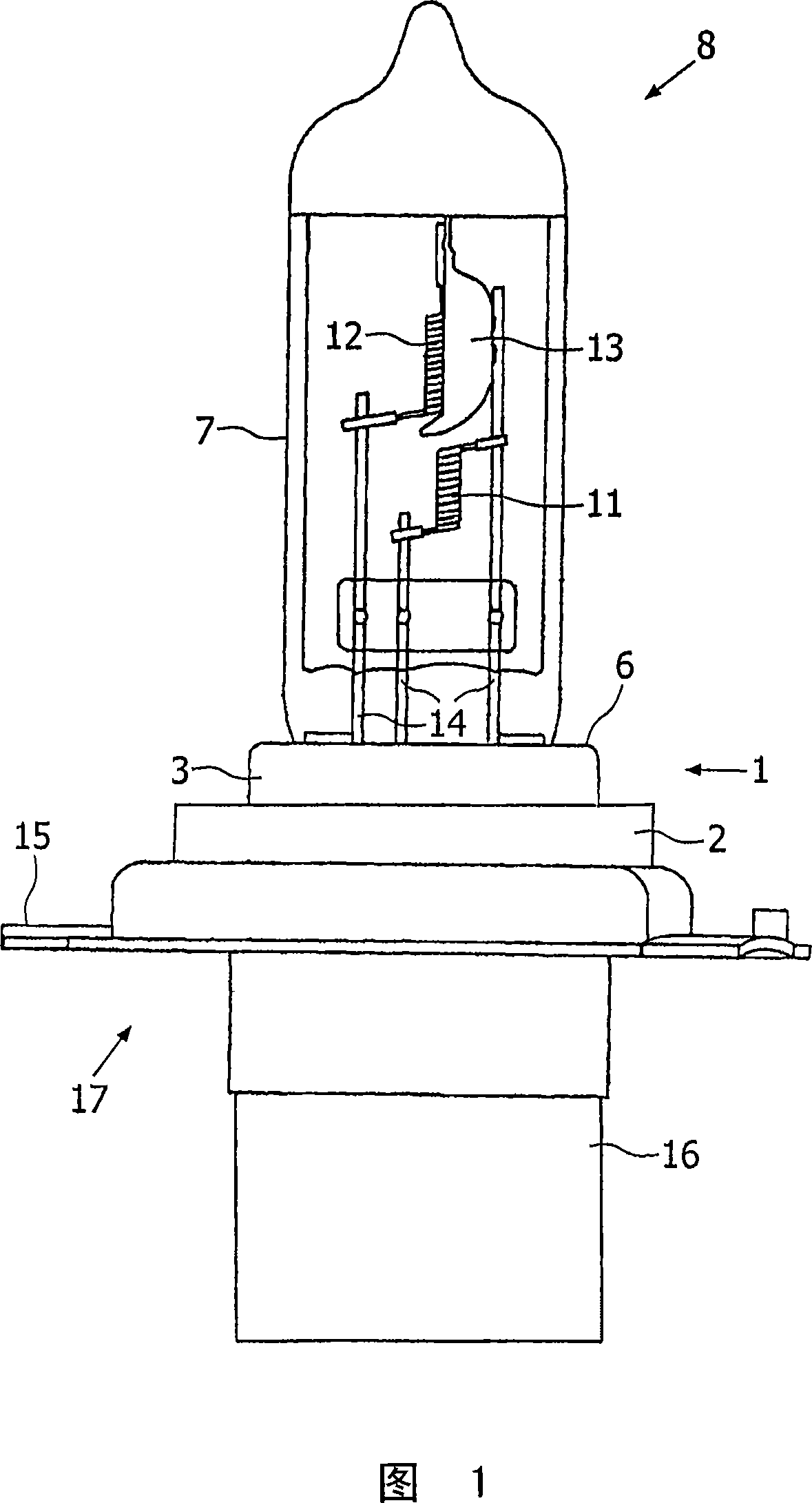

[0025] The exemplary embodiment of a lamp 8 according to the invention shown in FIG. 1 is a lamp 8 for a headlight (not shown in this case) of a motor vehicle.

[0026] The lamp 8 has a base 7 formed by a glass envelope in which two incandescent filaments 11 , 12 are located. The incandescent filaments 11 , 12 are supplied with current via fusible supply wires 14 which are fixed to corresponding terminal parts (not shown here) inside the socket 17 . One of the incandescent filaments 11 is provided with a dipped beam base 13 .

[0027] The positioning flange 15 and the terminal area 16 together form a socket 17 . The joint plate 1 is welded to a positioning flange 15 which is used to align the lamp 8 in the headlamp.

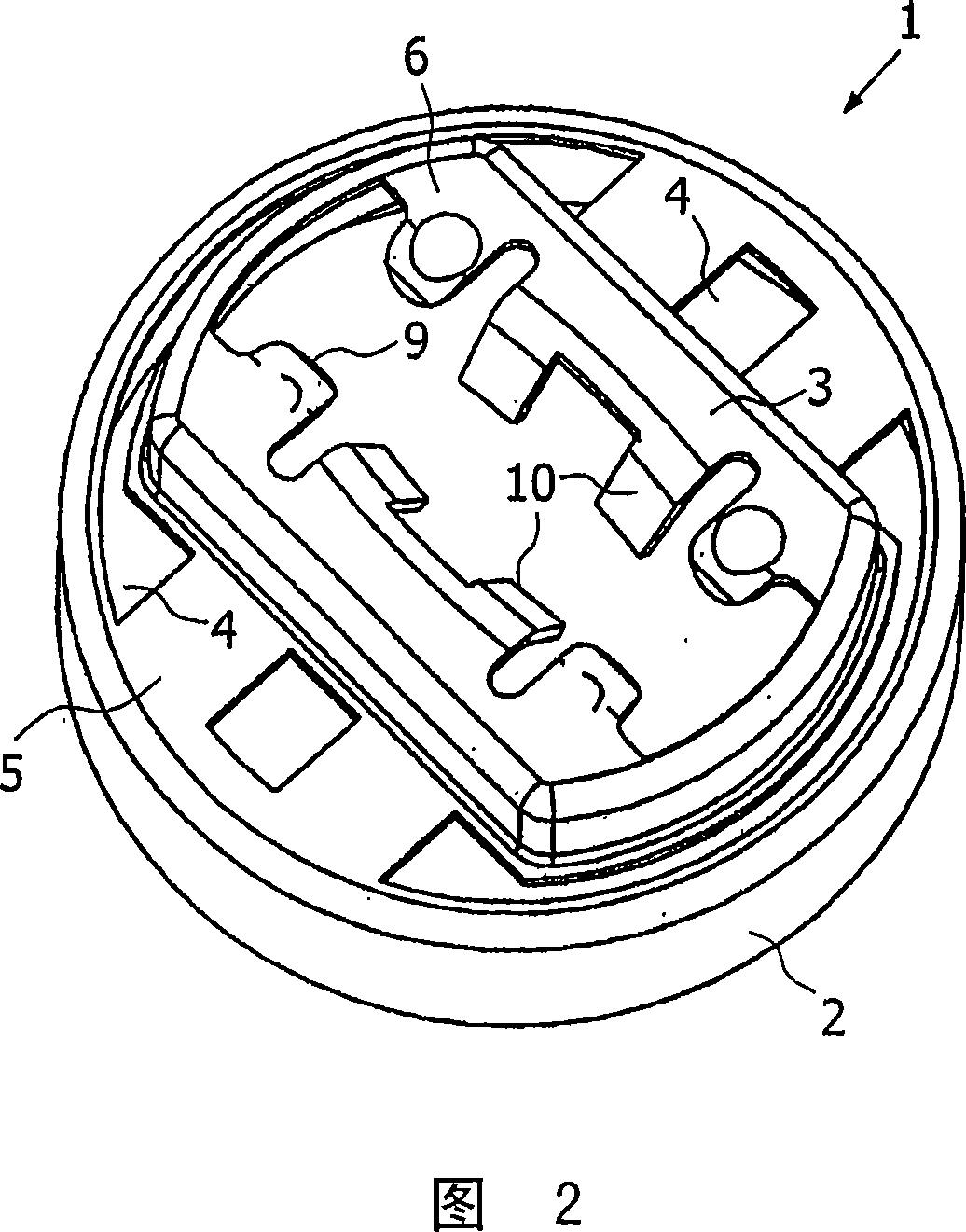

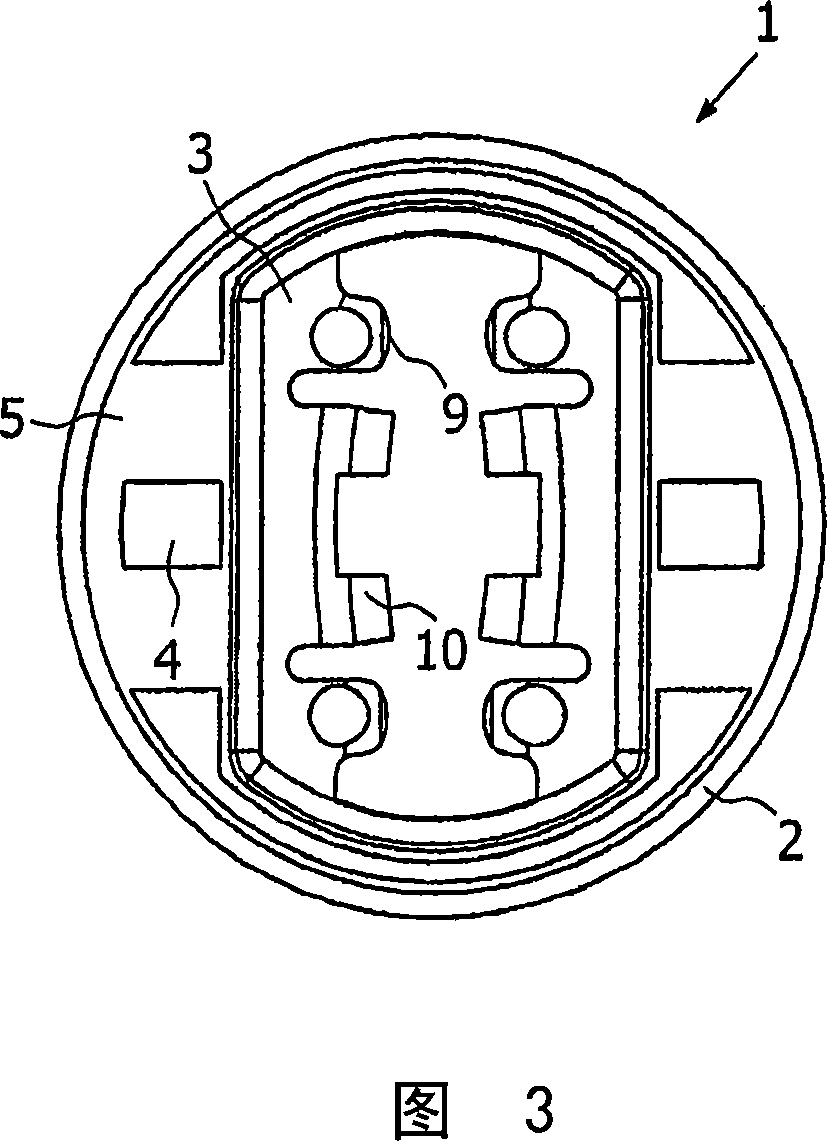

[0028] By means of the end of the cap adjacent to the cap 17, the cap 7 is held in place by clamping in the opening 9 in the receptacle 3 of the terminal plate 1, in this case being pressed against the support tab 10 of the wider side of the cap 7 Fix the lamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com