Stake-barrel base

A bucket foundation and pile foundation technology, which is applied in the field of foundation structure types, can solve the problems of foundation level and uplift resistance, inapplicability of hard foundation and weak resistance to level, foundation settlement and horizontal displacement. Inappropriate control and other problems, to achieve the effect of reducing offshore construction operation time, high compressive bearing capacity, and reducing the number of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

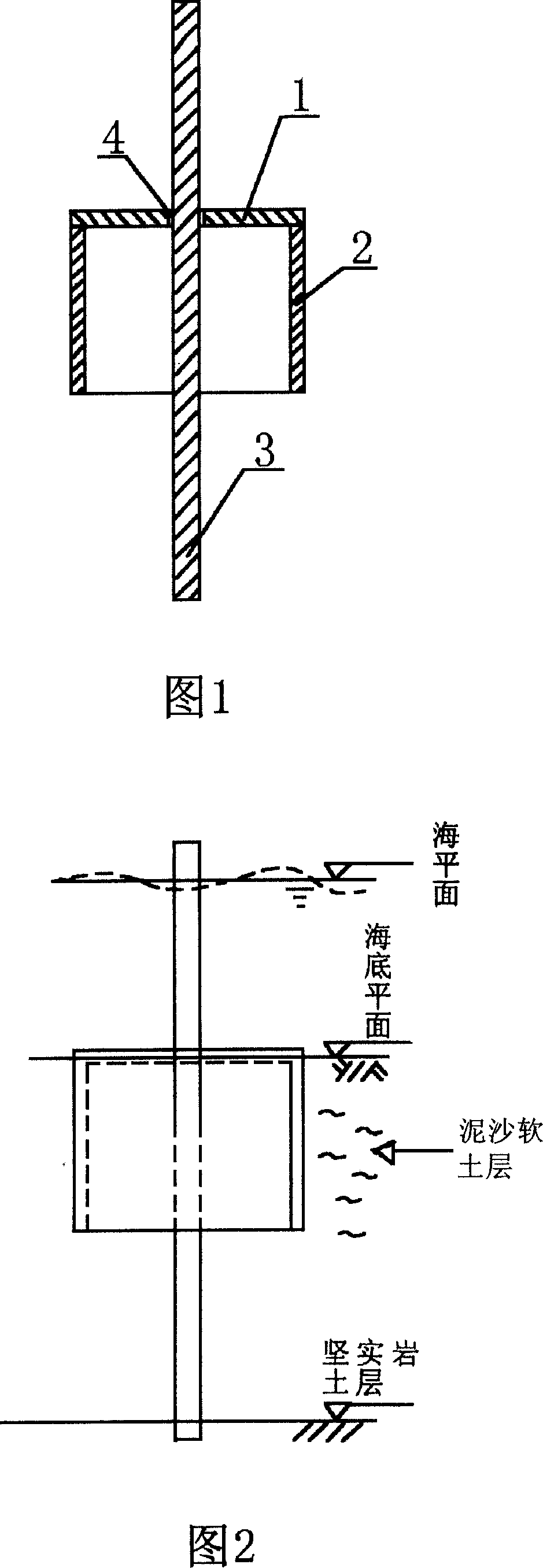

[0012] The structure of the pile-bucket foundation of the present invention will be described in further detail below in conjunction with the accompanying drawings.

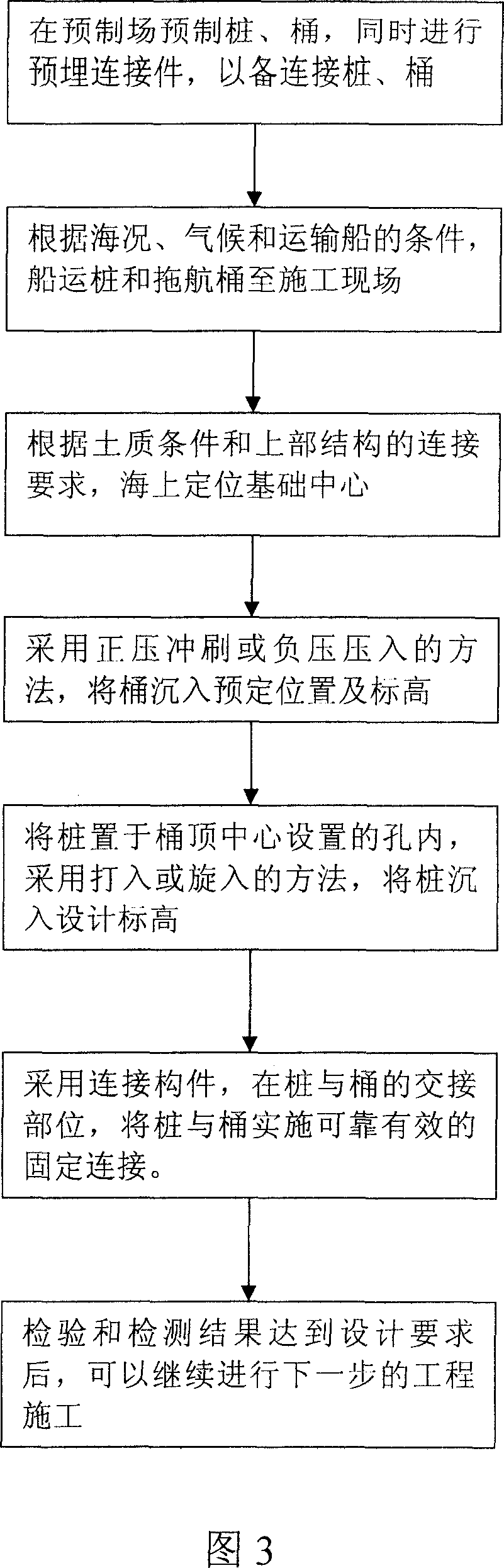

[0013] Referring to Fig. 1, 2 is a circular barrel shell, 1 is a circular top cover on the top of the barrel shell 2, and a hole 4 is set in the center of the top cover 1. Put the pile 3 through the hole 4 of the top cover 1 to form a "towel"-shaped pile-barrel foundation structure; the material of the pile-barrel foundation component is reinforced concrete or steel, the length and diameter of the pile 3, the height of the barrel shell 2 and The diameter, the thickness of the barrel shell 2 and the top cover 1, and the elevation of the pile-barrel foundation implanted into the seabed foundation are determined by the design requirements of marine engineering - bearing uplift, downward pressure, horizontal load and seabed foundation conditions. See Figure 2. When installing and constructing pile-bucket foundations ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com