Improved thermostatic control method and system for engine test-bed engine oil

A test bench and engine oil technology, applied in the field of vehicle testing, can solve problems such as wear, affecting the pressure of the main oil passage of the engine oil, unreasonable engine oil cooling control, etc., and achieve the effect of low cost and high precision of engine oil temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

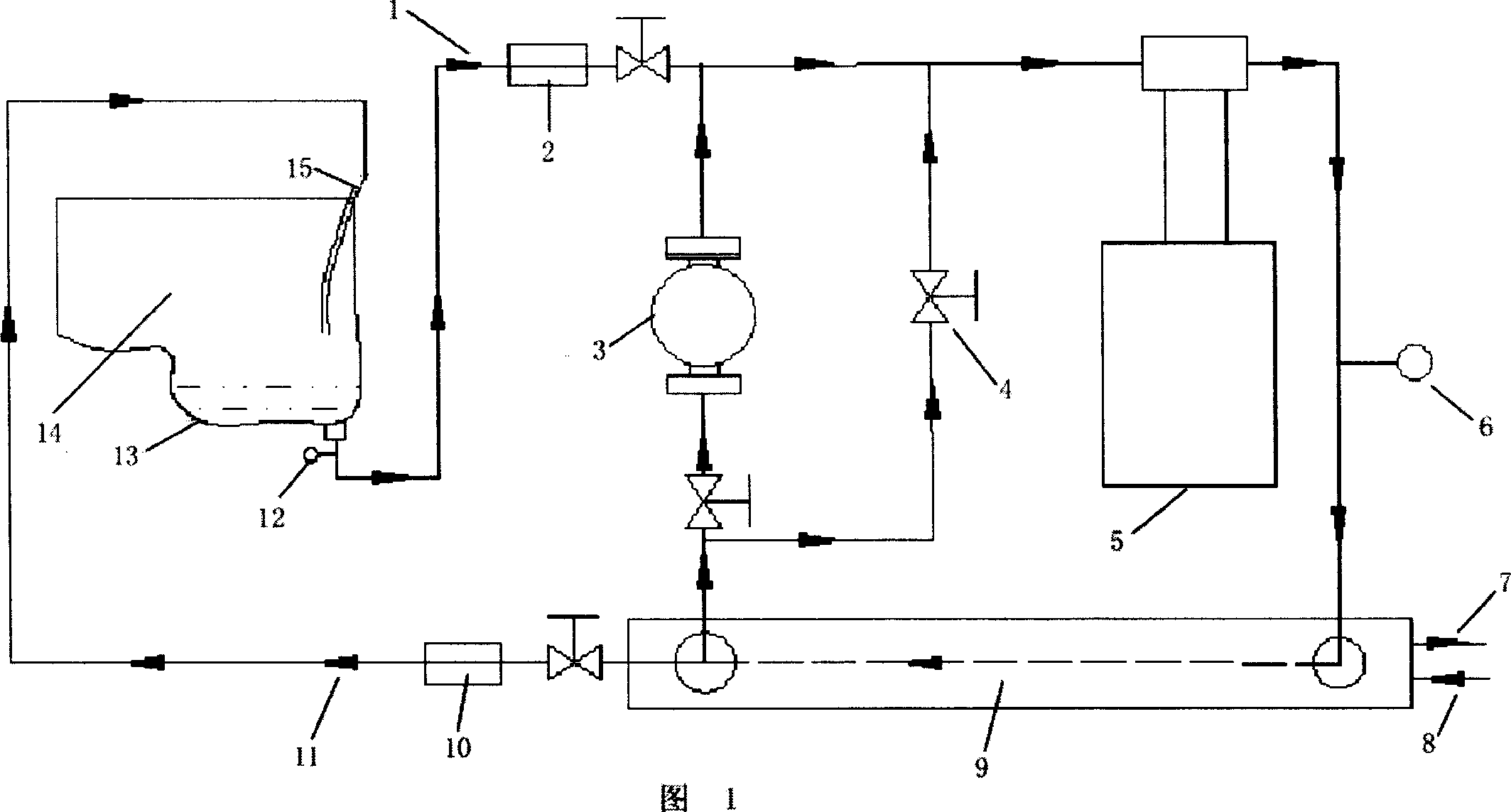

[0020] As shown in Fig. 1 , an embodiment of the present invention, the engine oil is extracted from the oil drain blockage of the oil pan 13 of the engine 14 through the high temperature resistant oil pump 5 and cooled by the cooler 9, from the heat exchange pipe of the oil cooler 9 The cooling water 8 flows outside, and the cooling water 8 flows through the inside of the heat exchange pipe of the oil cooler, and the cooling water 8 can take away the heat of the engine oil, thereby reducing the temperature of the engine oil. The oil pump 5 adopts high temperature resistant, so that the flow rate of the oil pump 5 can meet the maximum circulation flow rate of the engine 14 oil sump 13 machine oil. The oil cooler 9 also adopts high temperature and high pressure resistant to ensure that the oil cooler works for a long time at a pressure of 0.8MPA and a maximum temperature of 120°C. After the cooled machine oil is filtered through the filter 10, the oil is discharged to ensure th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com