Air intake mode of the fuel battery

A fuel cell and single cell technology, applied in the direction of fuel cell additives, etc., can solve the problems of poor battery performance, reduce humidity, etc., achieve the goals of improving water distribution, reducing concentration polarization, and improving stability and life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

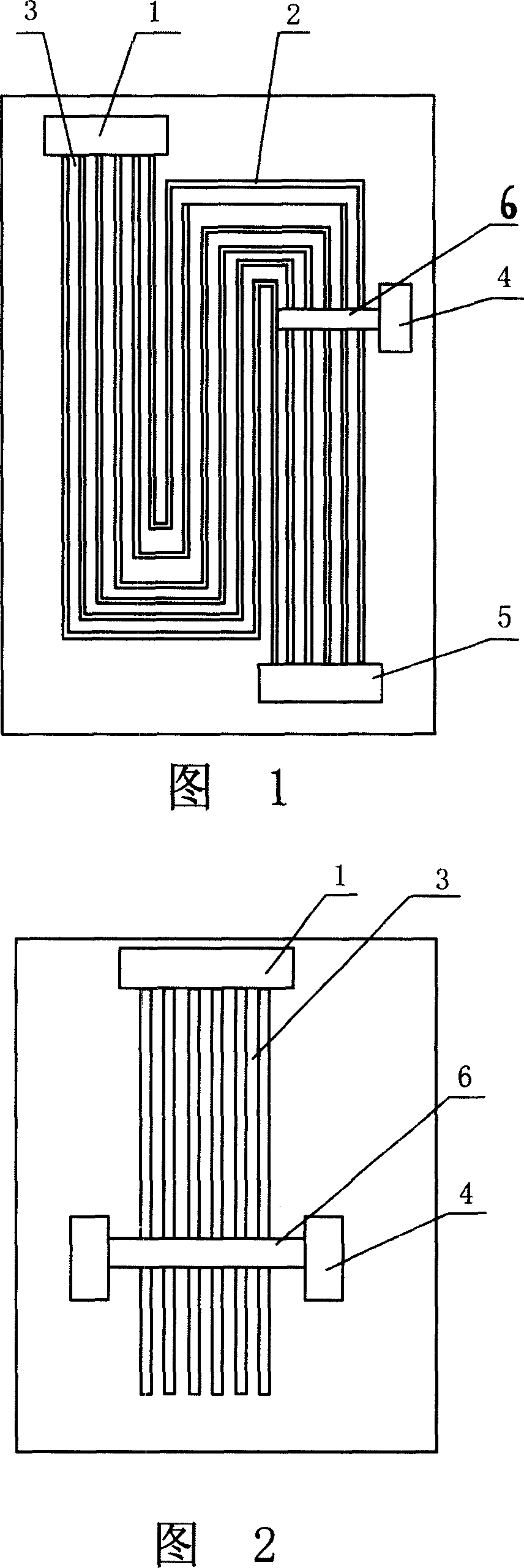

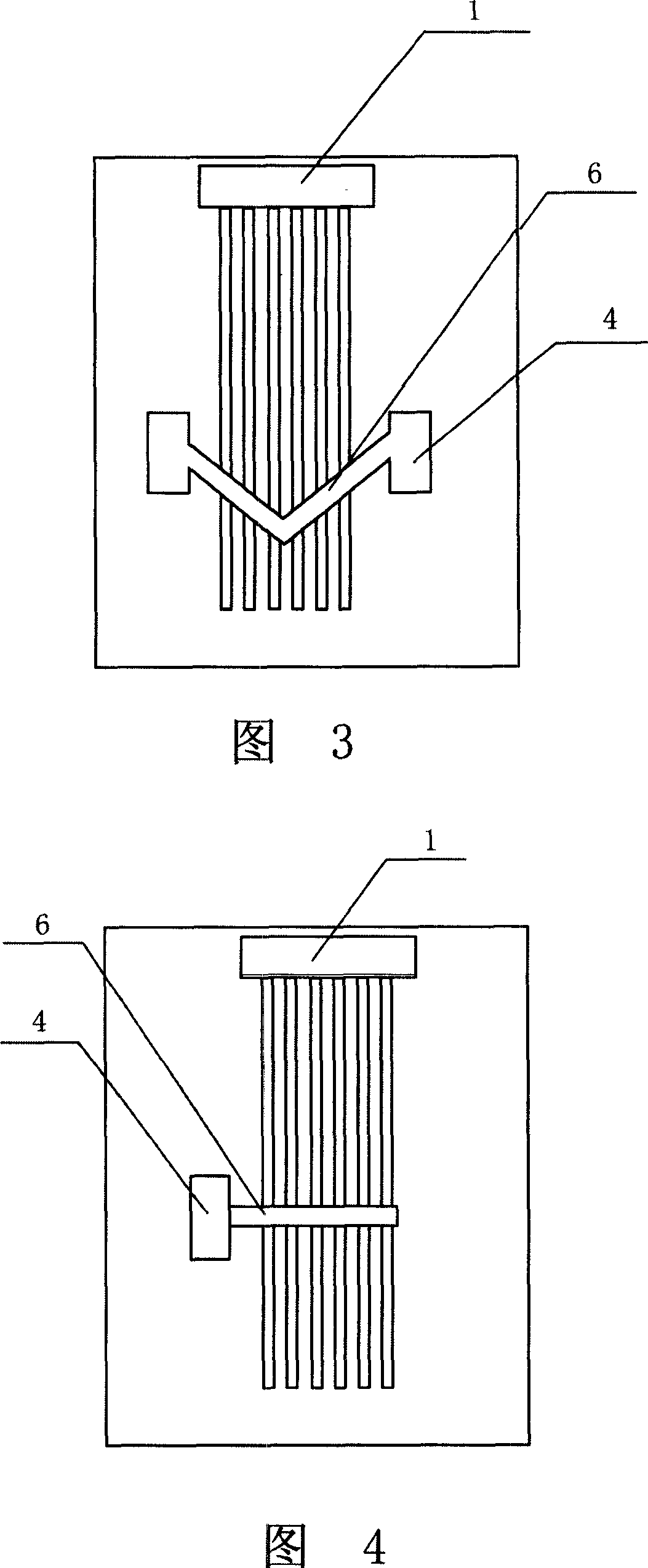

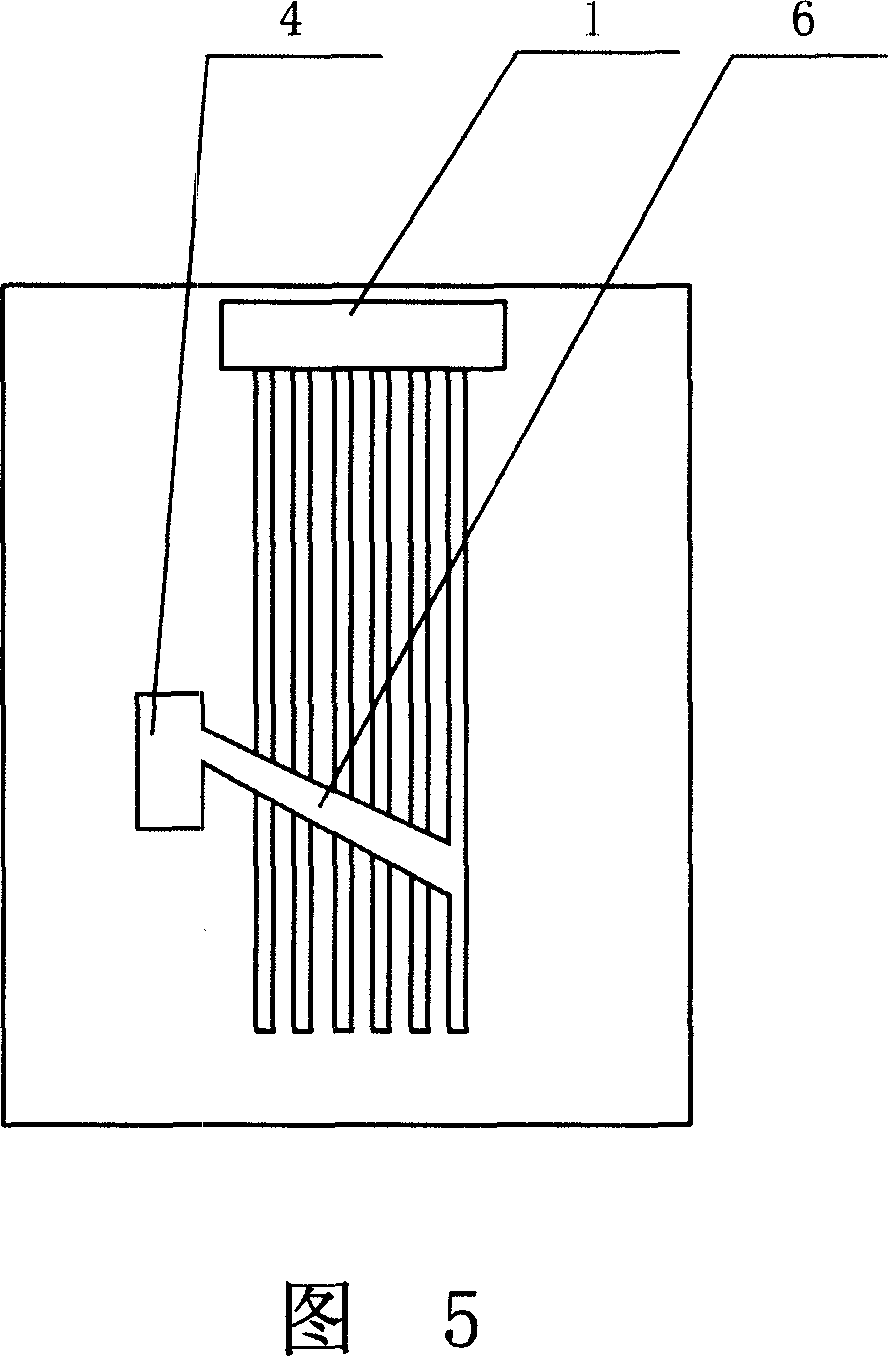

[0021] Referring to Figure 1, a fuel cell is composed of several single cells fixed by end plates on both sides, and each single cell is composed of a cathode flow field plate, an anode flow field plate, a diffusion layer, a catalytic layer and a proton exchange membrane. The flow channel 2 of the flow field plate of the single cell takes in air through the main air inlet 1 and air out through the air outlet 5 . To realize the secondary air intake, the secondary air intake 4 is mainly added on the cathode flow field plate or the anode flow field plate, and the secondary air intake 4 communicates with the flow channel 2 . Adding the secondary air inlet 4 on the flow field plate is not only applicable to the multiple serpentine flow channels in the figure, but also applicable to other flow channels such as straight flow channels and single serpentine flow channels.

[0022] The position of the secondary air inlet 4 is not limited to the position in the figure, generally it shoul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com