A rotating electrical machine with a transmission and a driving apparatus using the same

A technology of speed change mechanism and rotating electrical machine, applied in electromechanical devices, electric components, synchronous machines, etc., can solve the problems of hard resin material sealing, enlarged motor shape, large surface area of excitation coil, etc., and achieve the effect of small outer diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

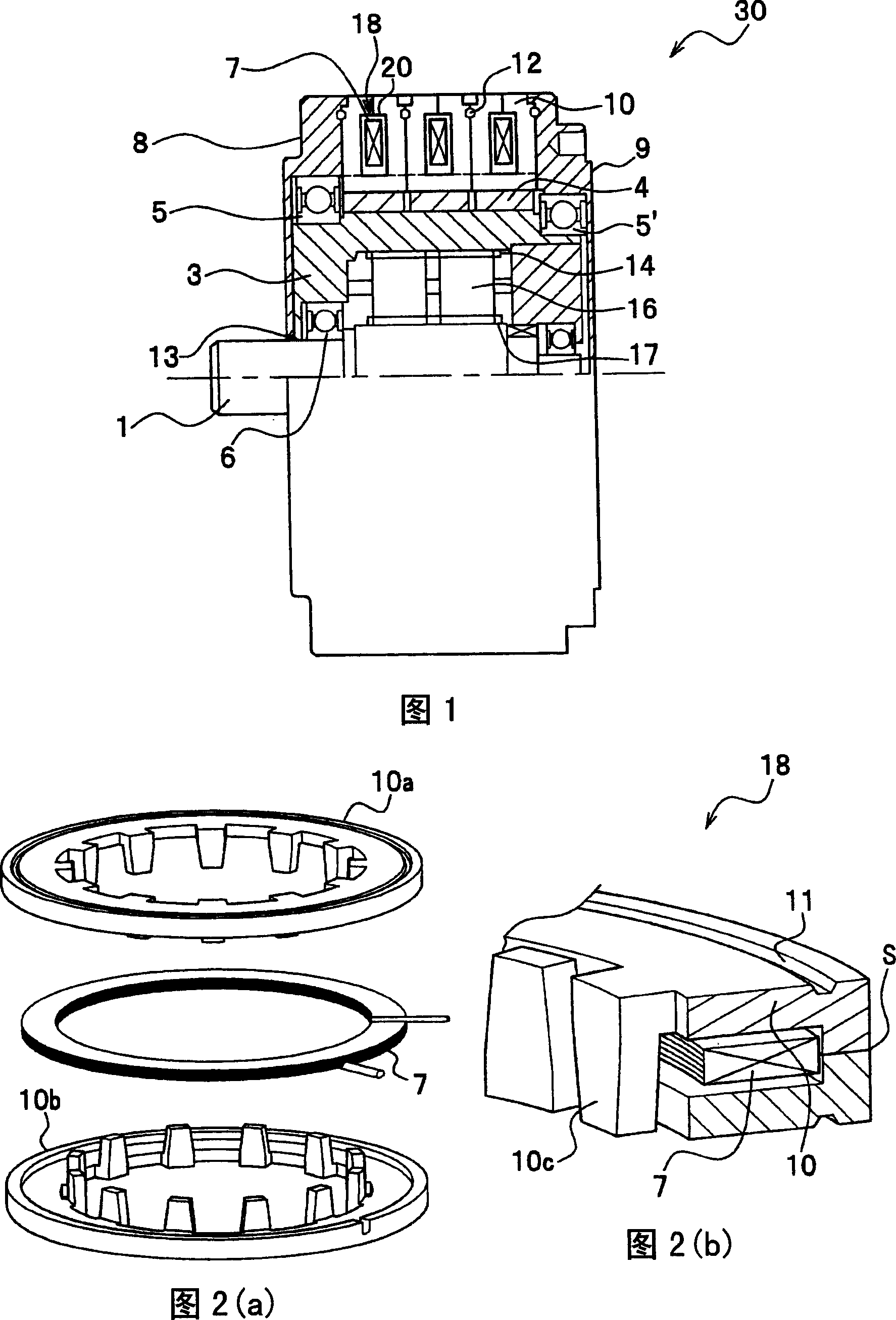

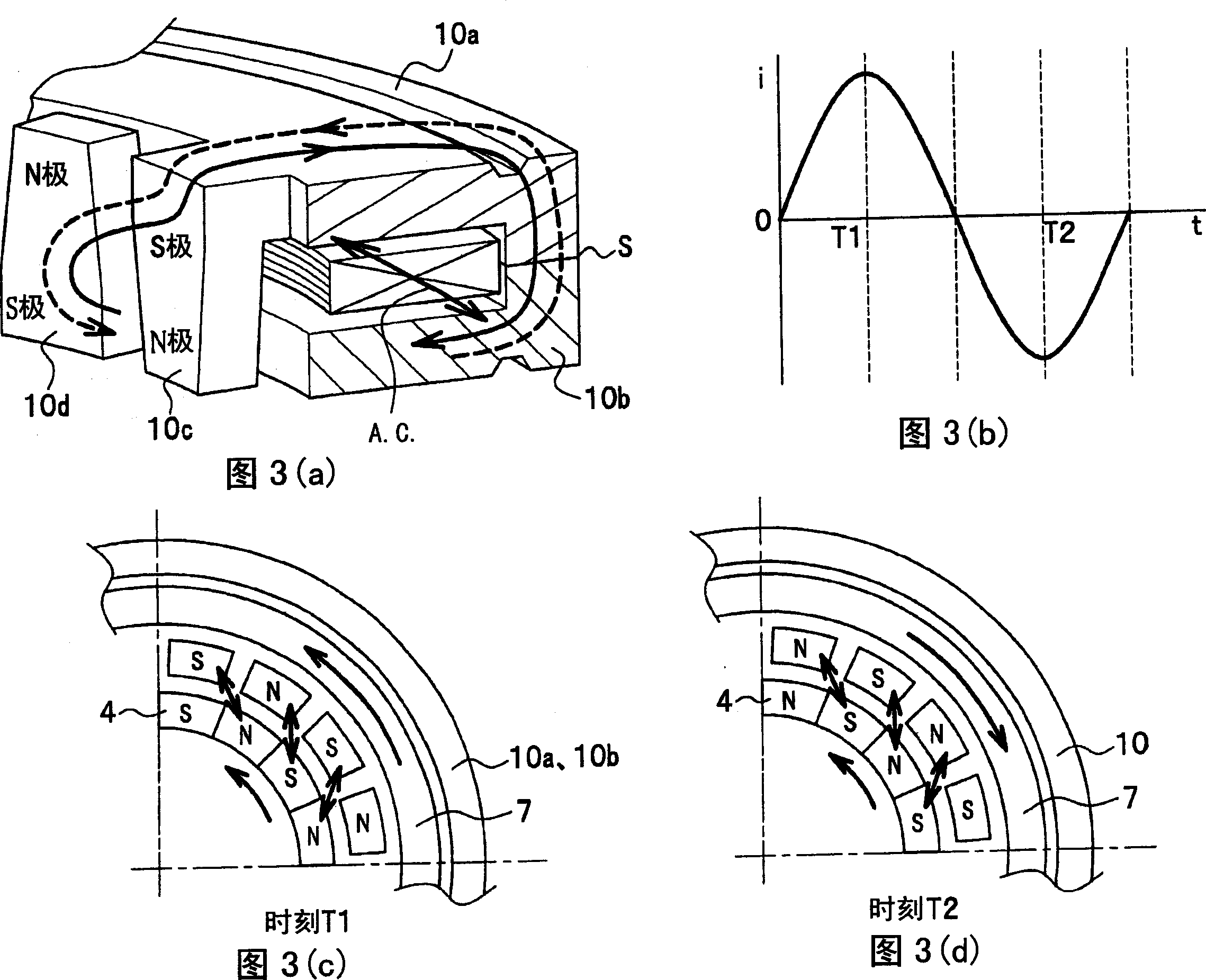

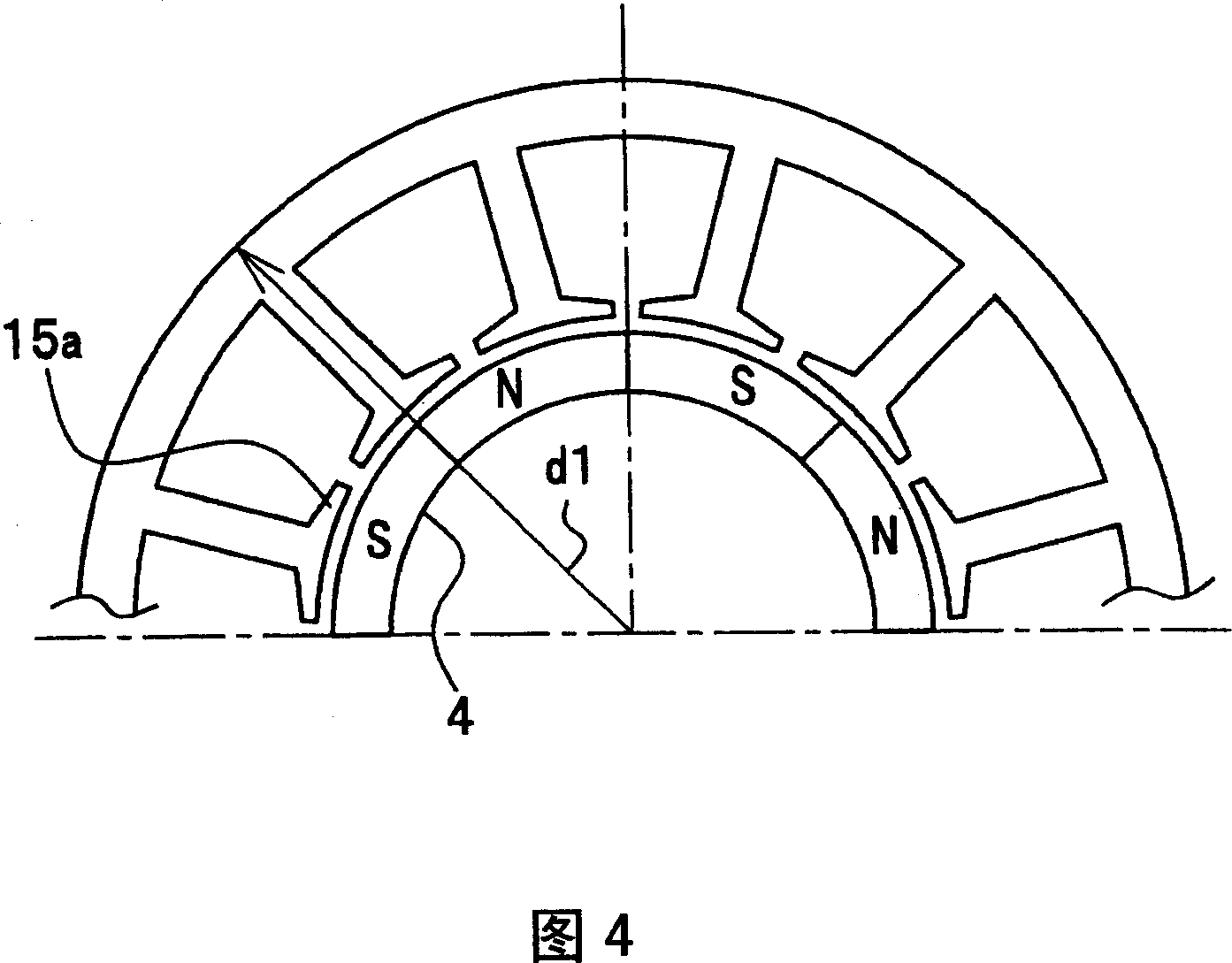

[0025] Referring to FIG. 1 and FIG. 2 , an embodiment of the present invention, that is, a rotating electrical machine with a transmission mechanism will be described. 1 is a cross-sectional view of a geared motor 30 that is a rotating electric machine with a speed change mechanism, and FIG. 2 is a perspective view showing a claw core 10 used in a stator of the geared motor 30 .

[0026] In FIG. 1 , the main structure of the deceleration motor 30 of this embodiment includes: three stators composed of field coils 7 arranged inside the annular claw-tooth iron core 10; a rotating shaft 3 of a cylindrical rotor 4; and a transmission mechanism (described later) provided inside the rotating shaft 3 to reduce the rotational speed of the output shaft 1 .

[0027] In FIG. 2 , the stator 18 has: two annular claw-tooth iron cores 10a, 10b made of a soft magnetic material such as a dust core; The tooth cores 10a and 10b are configured so that the field coil 7 can be housed, and are seale...

no. 2 Embodiment approach

[0046] The above-described embodiments have been described with respect to an electric motor as a rotating electric machine, but may be configured as a drive device using the electric motor. An automotive machine or a mobile robot as shown in Fig. 7 is considered as an example of a driving device.

[0047] By using the arm joints of a mobile body such as a mobile robot (self-propelled robot) shown in FIG. 7 that require a large torque for rotation, the weight of the mobile body can be reduced and the battery life of the mobile body can be ensured. On the mobile robot 31, a geared motor 30 is mounted on a main body that can move in the front and rear directions by means of wheels 33. The geared motor 30 rotates the rotating arm 32a in the horizontal direction, and the other geared motor built in the rotating arm 32a rotates it. The arm 33b rotates in the horizontal direction.

[0048] In addition, in automobile machines, since multiple electric motors are used on each machine,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com