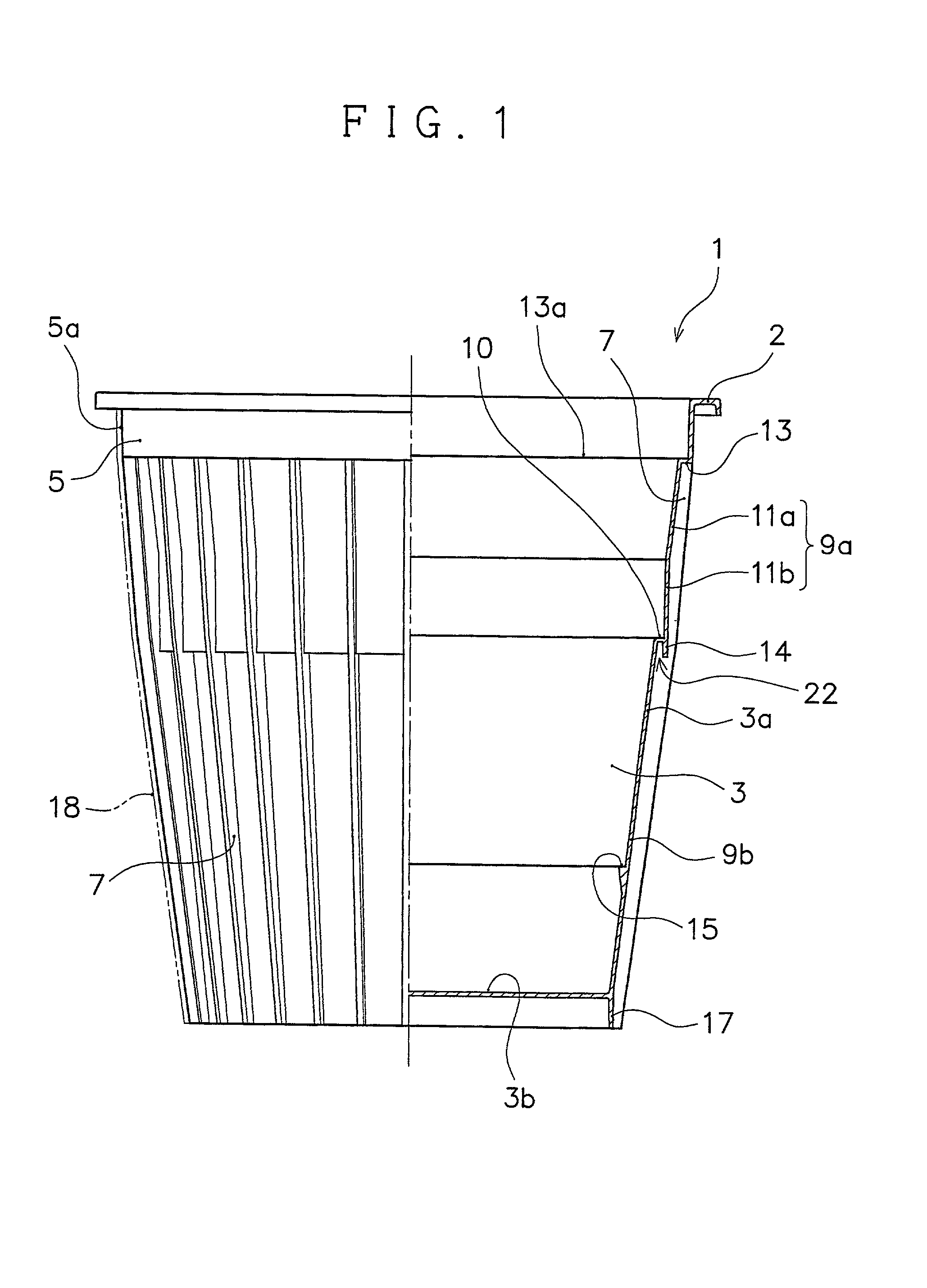

Heat-insulating container

a container and heat insulation technology, applied in the field of heat insulation containers, can solve the problems of deteriorating the strength of the container body, user is unlikely to overheat, and deteriorating the strength of the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

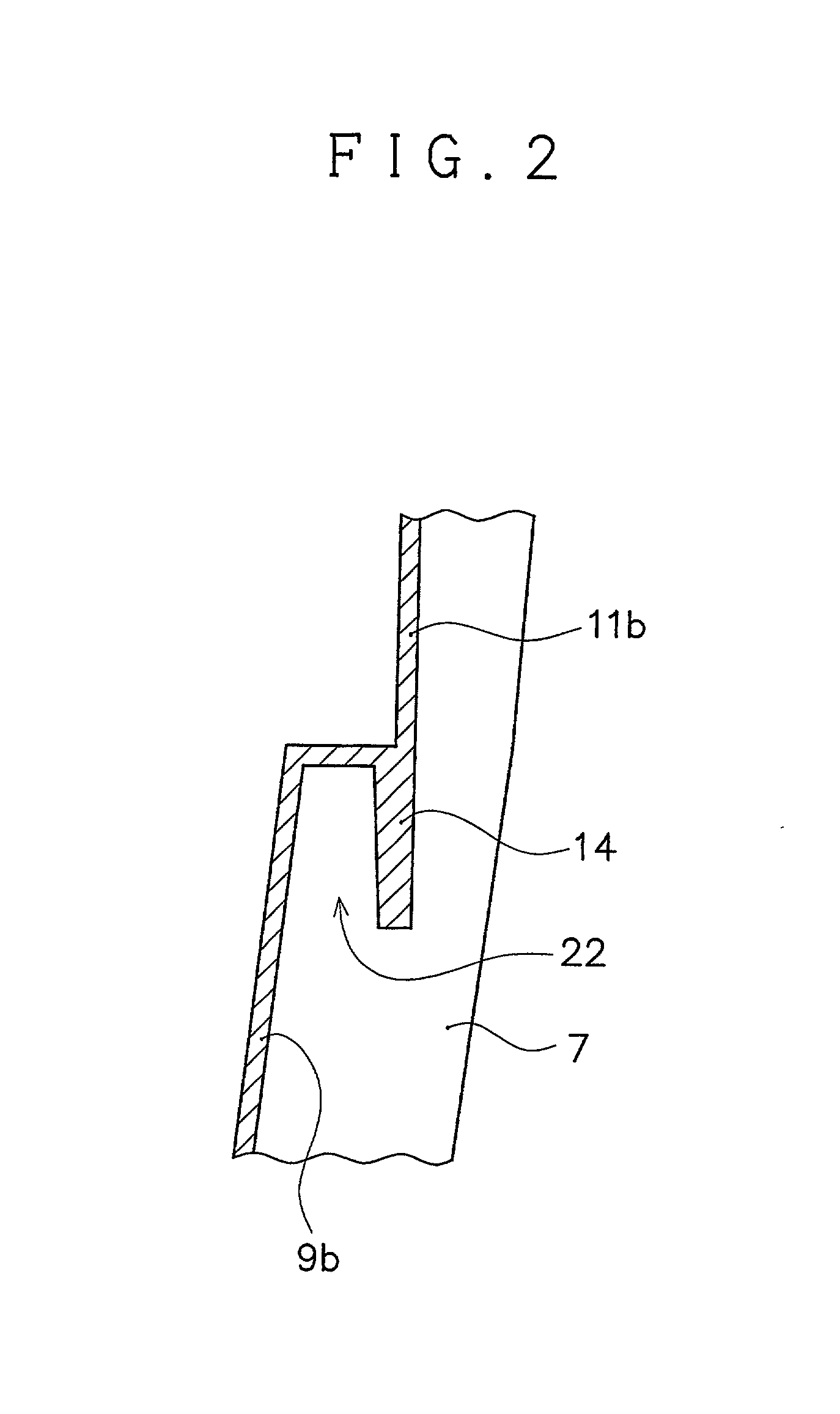

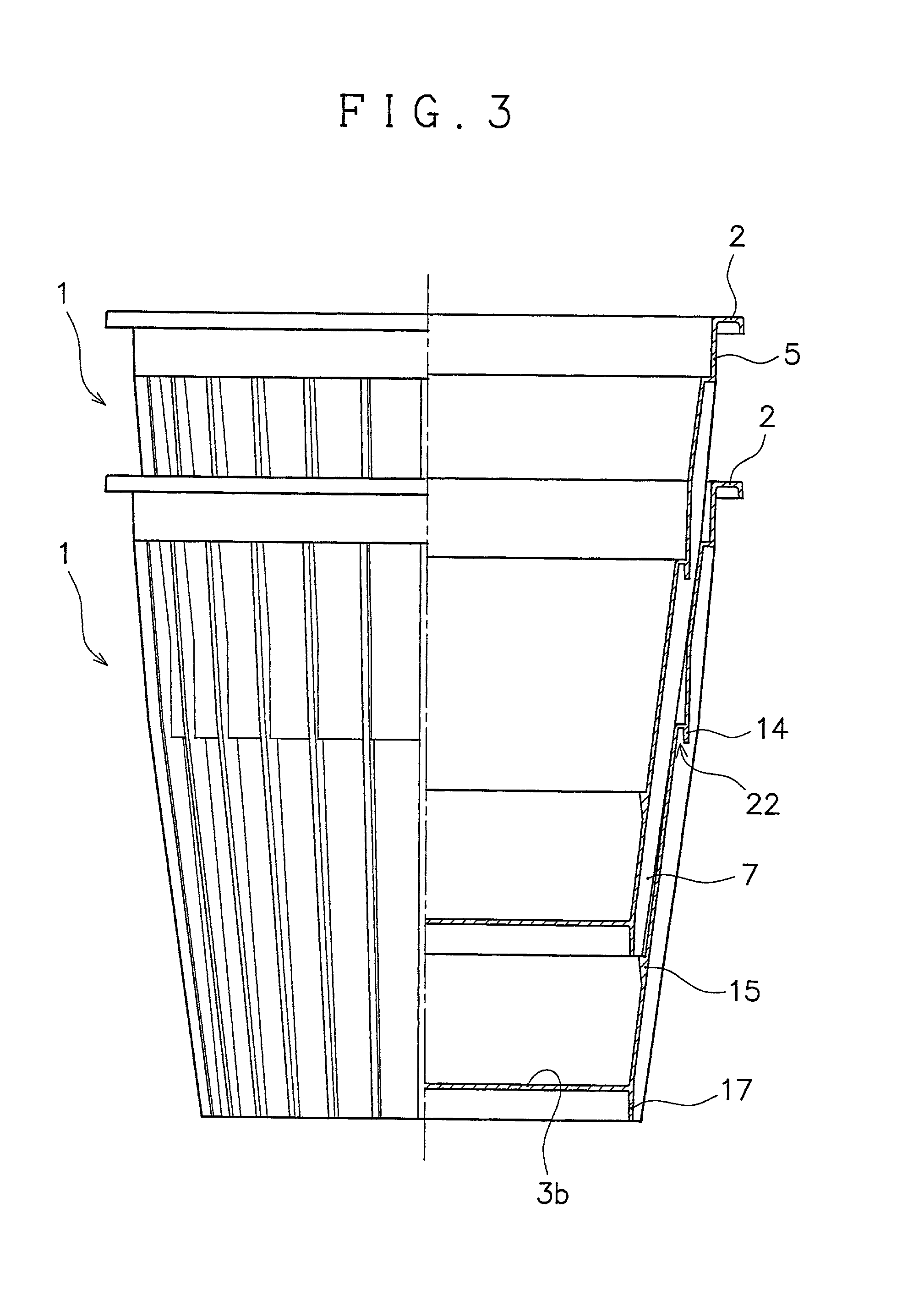

Embodiment Construction

260 137.2M 9.2 2 Example 2 250 156.8M 9.1 6

[0057] To determine the formability in each example, the occurrence of short shot near the upper open end of each container was visually observed through insufficiently formed portion of the container. A container on which no short shot was observed, was determined as being made with a good formability. No short shot was observed in the Examples 1 and 2, which were therefore determined as being formed with a good formability. On the other hand, short shot was observed in the Comparative Example, which was therefore determined as being formed with a poor formability.

[0058] It is to be noted that the present invention is not limited to the first to fourth embodiments as described above. For example, a container of the present invention can be used for containing therein not only dried noodles to be cooked with hot water but also hot coffee or cold drink. The shape of the container body 3 is also not limited to a circular shape in plan. Rather...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com