Electronic vent valve

a technology of electronic vent valve and valve body, which is applied in the direction of brake system, brake components, transportation and packaging, etc., can solve the problems of affecting the operation of the brake valve, so as to achieve reliable operation and efficient manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

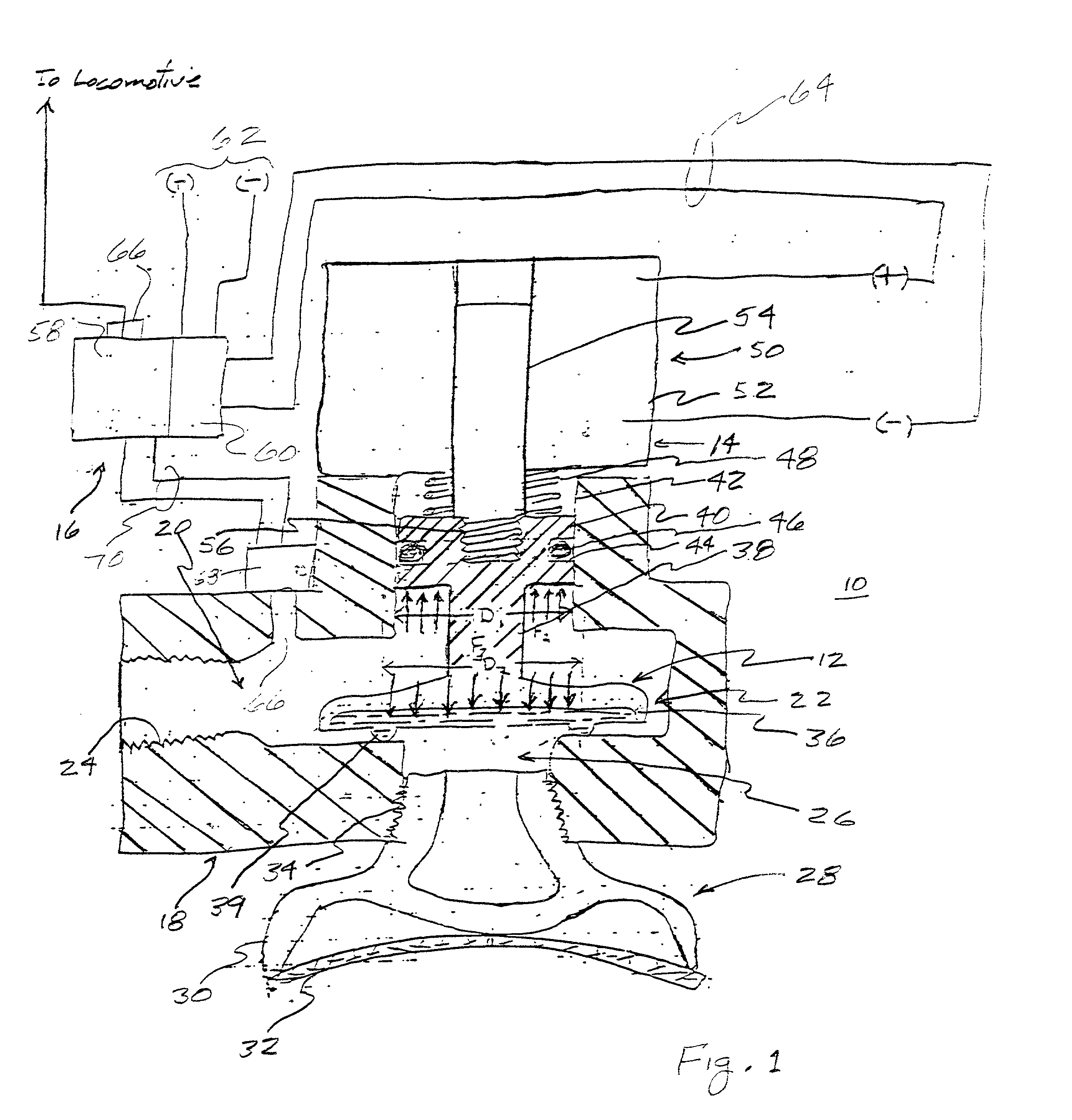

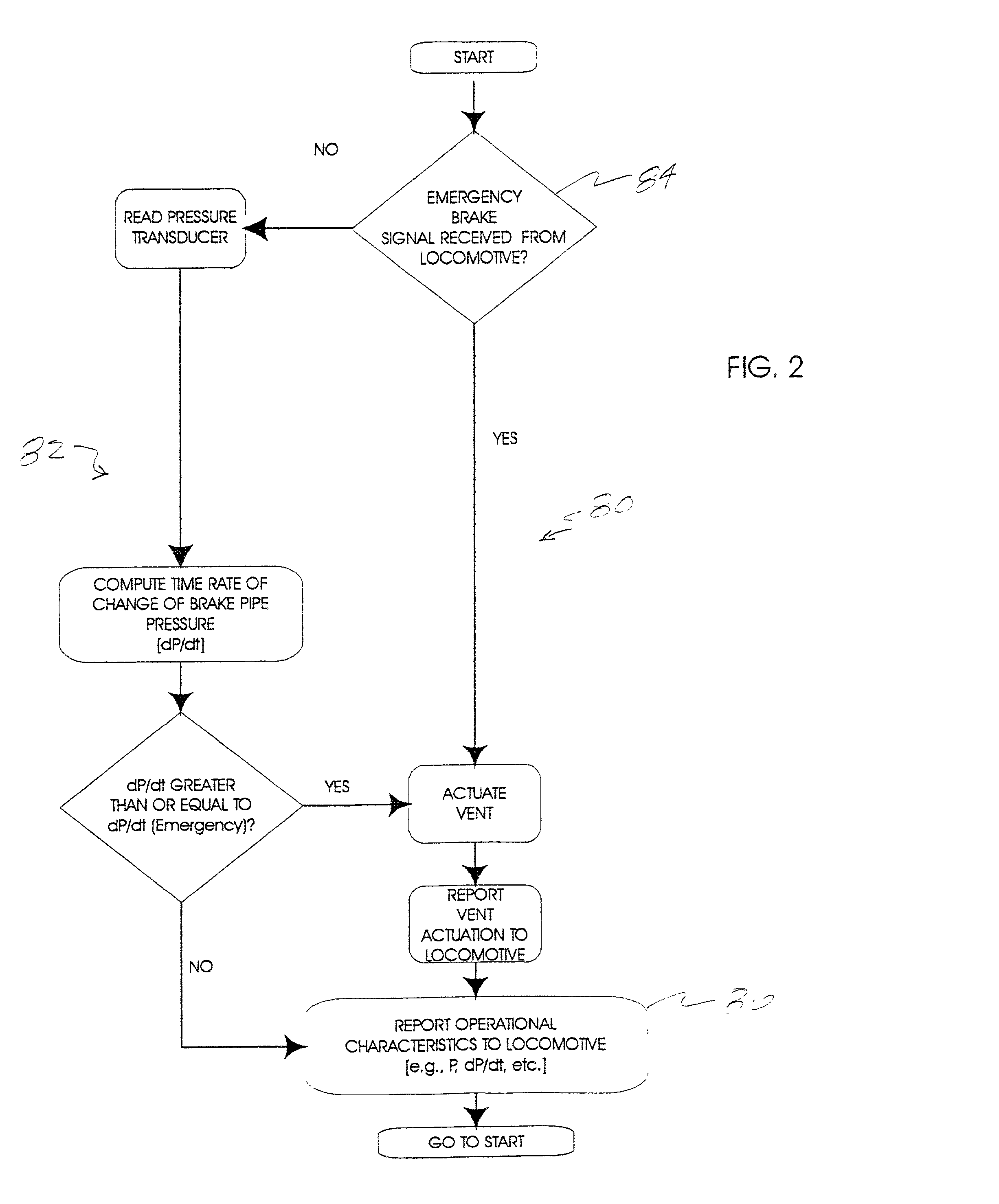

[0026] FIG. 2 is a flow chart showing an algorithmic procedure implemented by a microprocessor component of the electronic vent valve of FIG. 1.

second embodiment

[0027] FIG. 3 is a flow chart showing an algorithmic procedure implemented by a microprocessor component of the electronic vent valve of FIG. 1.

third embodiment

[0028] FIG. 4 is a flow chart showing an algorithmic procedure implemented by a microprocessor component of the electronic vent valve of FIG. 1.

[0029] Prior to proceeding to a much more detailed description of the present invention, it should be noted that identical components which have identical functions have been identified with identical reference numerals throughout the several views illustrated in the drawing Figures for the sake of clarity and understanding of the invention.

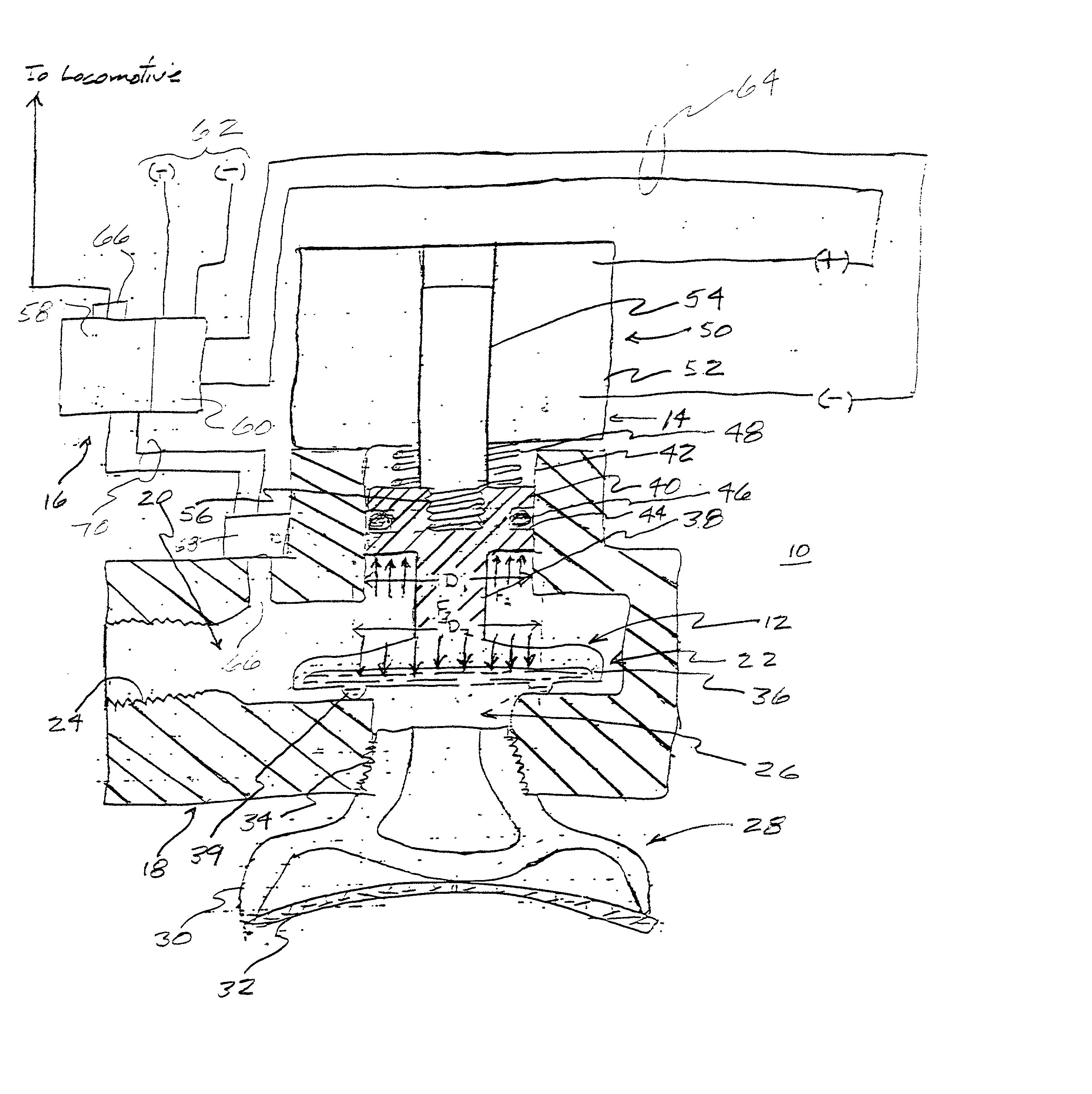

[0030] Referring now to FIG. 1, an electronic vent valve constructed according to the present invention and designated by reference numeral 10 generally includes a valve 12, an electrically operated actuator 14 for moving the valve 12 between an open position and a closed position and a control circuit 16 for controlling the electrically operated actuator 14 so as to cause the electrically operated actuator 14 to move the valve 12 between the open and closed position in accordance with algorithmic procedu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com