Electrolytic solution for non-aqueous type battery and non-aqueous type secondary battery

a technology of non-aqueous type batteries and electrolytic solutions, which is applied in the direction of secondary cells, cell components, non-aqueous electrolyte cells, etc., can solve the problems of significant deterioration of battery characteristics, insufficient safety assurance, and damage to the inherent performance of batteries, so as to ensure the safety of overcharging, excellent high-temperature storage characteristics, and low oxidation reaction potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

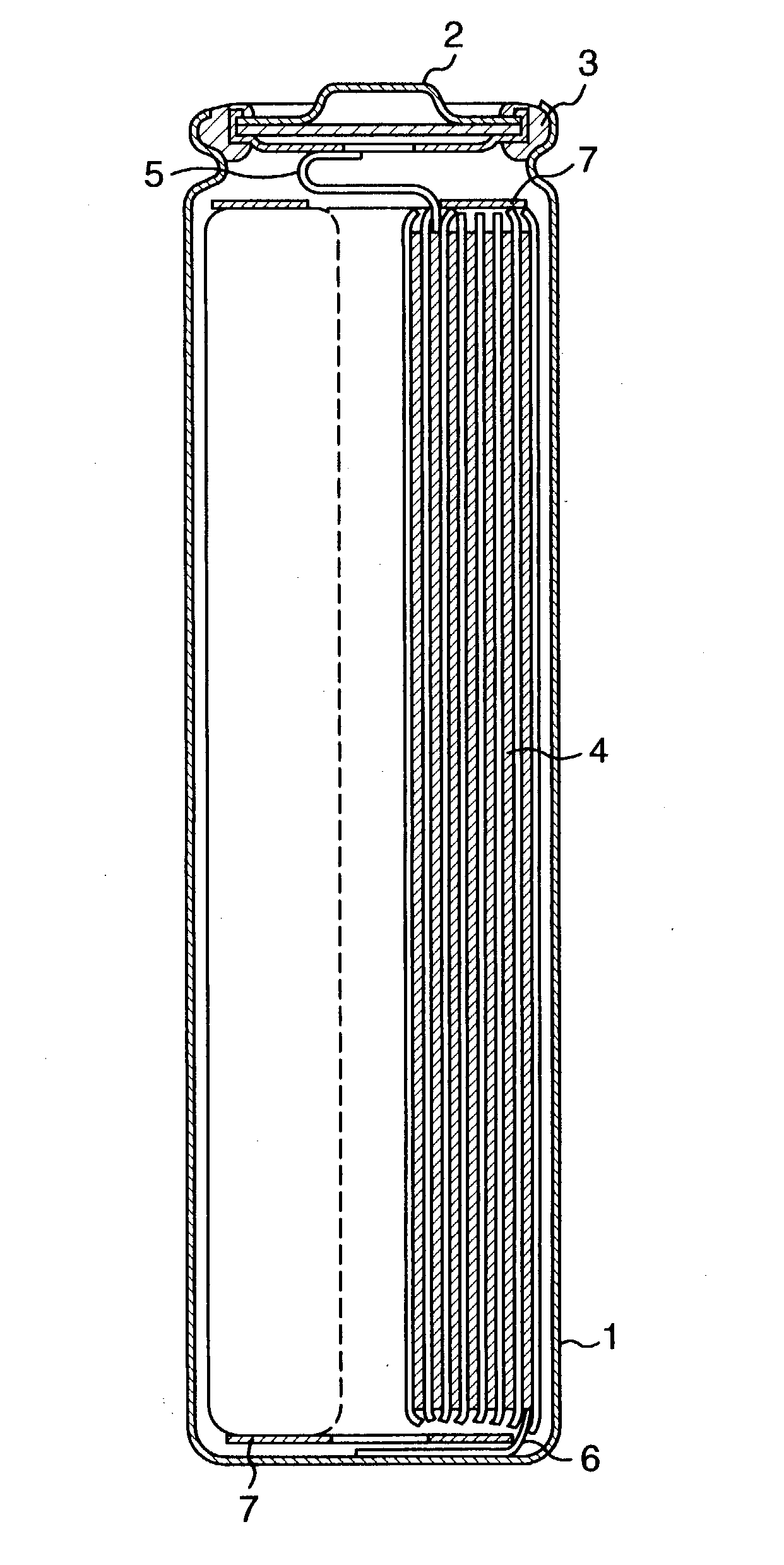

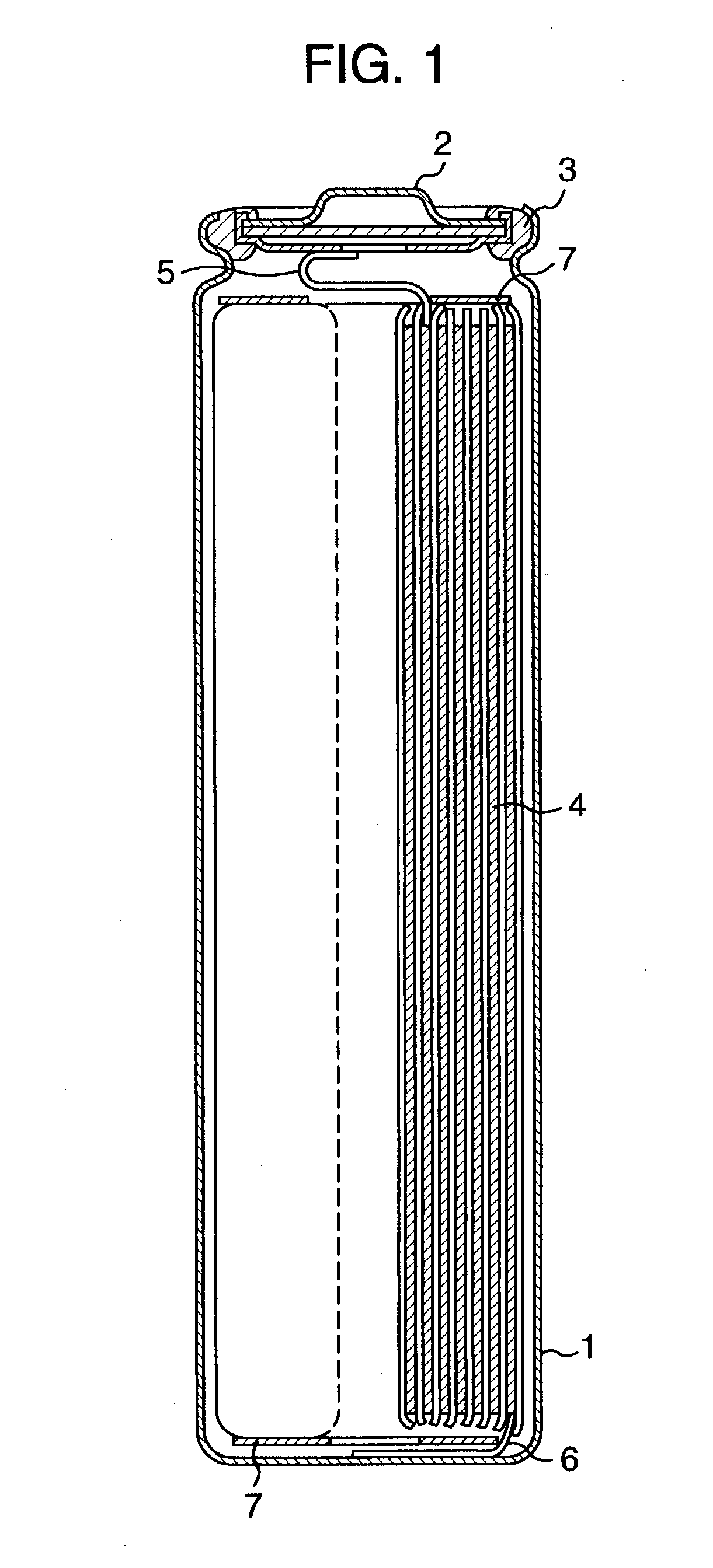

[0050] FIG. 1 is a longitudinal sectional view of the cylindrical battery used in this example. In FIG. 1, the reference numeral 1 indicates a battery case made by working a stainless steel plate having resistance to organic electrolytic solution, 2 indicates a sealing plate provided with a safety valve, 3 indicates an insulation packing, 4 indicates an electrode plate group, and positive electrode and negative electrode with separator interposed between the positive electrode and the negative electrode are rolled a plurality of times into a spiral form and inserted in the case 1. A positive electrode lead 5 is drawn from the positive electrode and connected to the sealing plate 2, and a negative electrode lead 6 is drawn from the negative electrode and connected to the bottom of the battery case 1. The reference numeral 7 indicates an insulation ring, which is provided at the upper and lower portions of the electrode plate group 4. The positive electrode, the negative electrode, an...

example 2

[0054] A cylindrical battery of spiral type was made in the same manner as in Example 1, except that cyclohexylbenzene in an amount of 2% by weight and biphenyl in an amount of 0.2% by weight based on the total amount of the electrolytic solution were used as the additives to the electrolytic solution. The thus obtained battery was referred to as battery 2 of the present invention.

example 3

[0055] A cylindrical battery of spiral type was made in the same manner as in Example 1, except that cyclohexylbenzene in an amount of 2% by weight and o-terphenyl in an amount of 0.2% by weight based on the total amount of the electrolytic solution were used as the additives to the electrolytic solution. The thus obtained battery was referred to as battery 3 of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com