Monitoring of critical dairy farm conditions

a critical dairy farm and monitoring technology, applied in the field of critical dairy farm conditions, can solve the problems of overriding the switch, rough indirect estimate of the temperature, and rough indirect estimate of the milk flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] (a) Description of FIG. 1

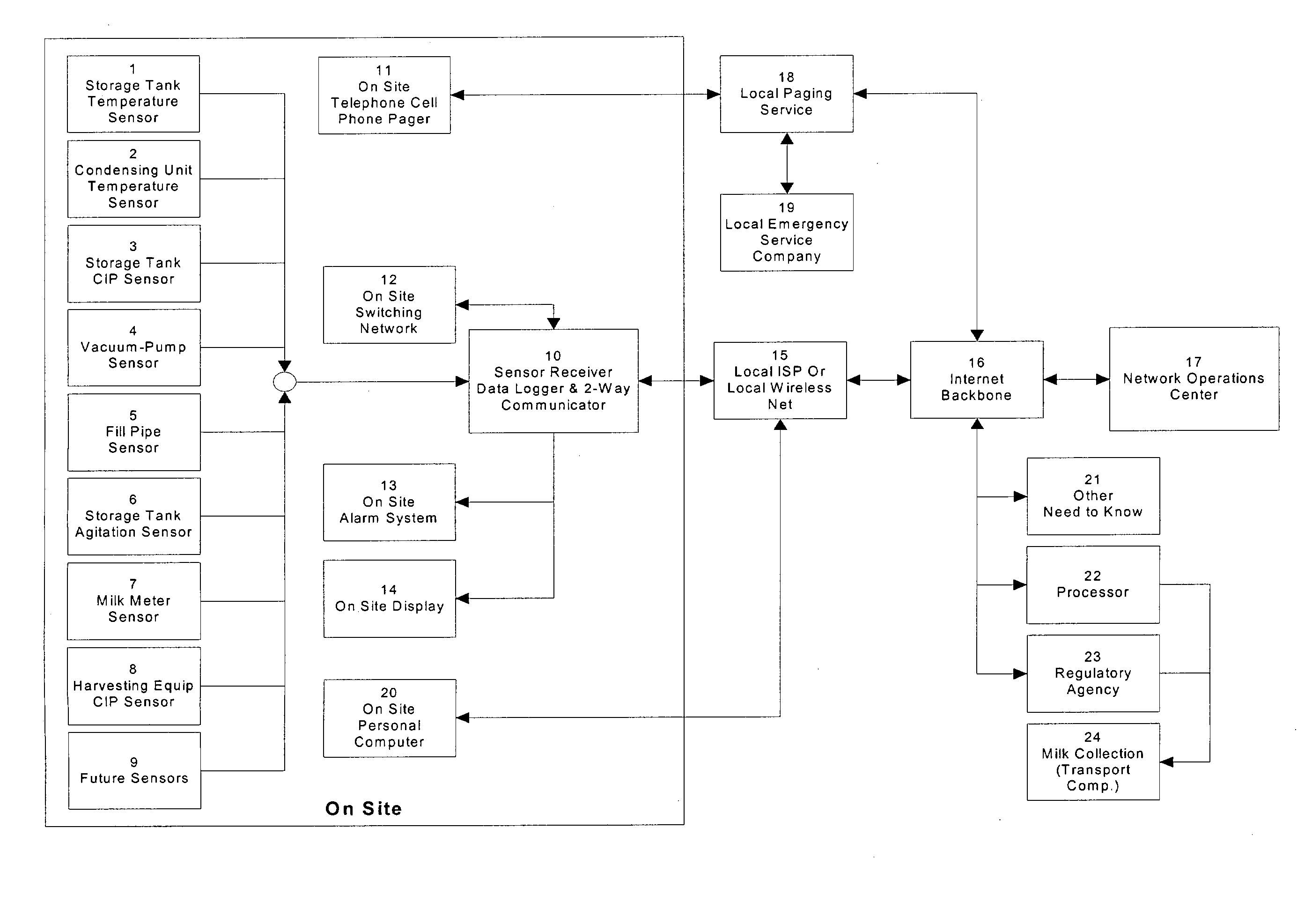

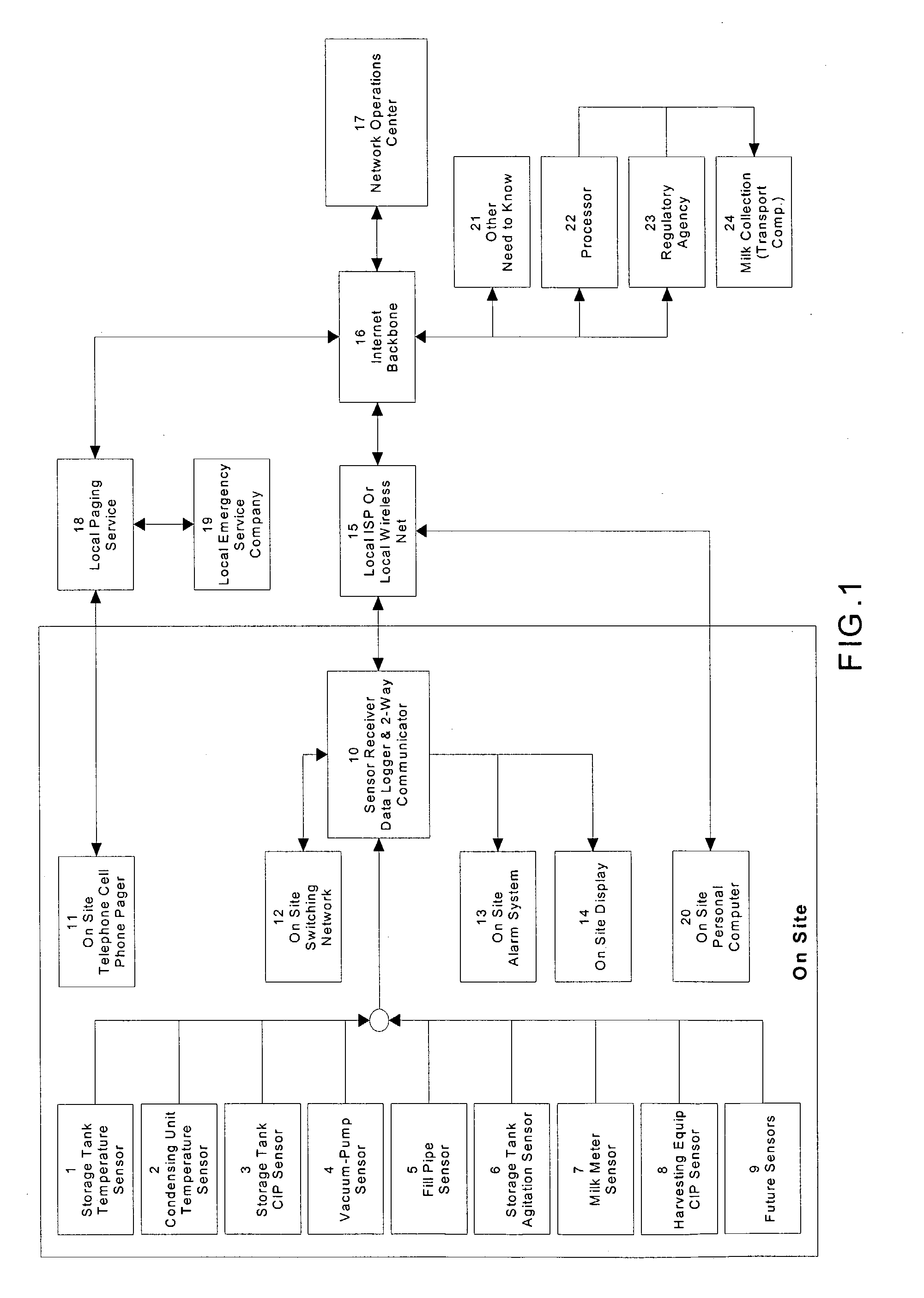

[0069] FIG. 1 depicts the discrete components of one system of an embodiment of this invention and the data flow path of information.

[0070] Reference numbers 1 through 9 depict possible sensors which are strategically placed on / in equipment on the farm. The data generated by these sensors is used to monitor the procedures on the farm and are provided "on-site". Thus, reference No. 1 represents the storage tank temperature sensor; reference No. 2 represents the condensing unit temperature sensor; reference No. 3 represents the storage tank clean-in-place sensor; reference No. 4 represents the vacuum pump sensor; reference No. 5 represents the fill pipe sensor; reference No. 6 represents the storage tank agitation sensor; reference No. 7 represents the milk meter sensor; reference No. 8 represents the harvesting equipment clean-in-place sensor; and reference No. 9 represents one or more future sensors.

[0071] The data from sensors reference Nos. 1 to 9 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com