Engine cooling system and method for making same

a technology for cooling systems and engines, applied in the direction of machines/engines, mechanical equipment, light and heating equipment, etc., can solve the problems of significant heat generation of engines, significant reduction of engine power output, so as to achieve enhanced cooling effect and efficient transfer of heat to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

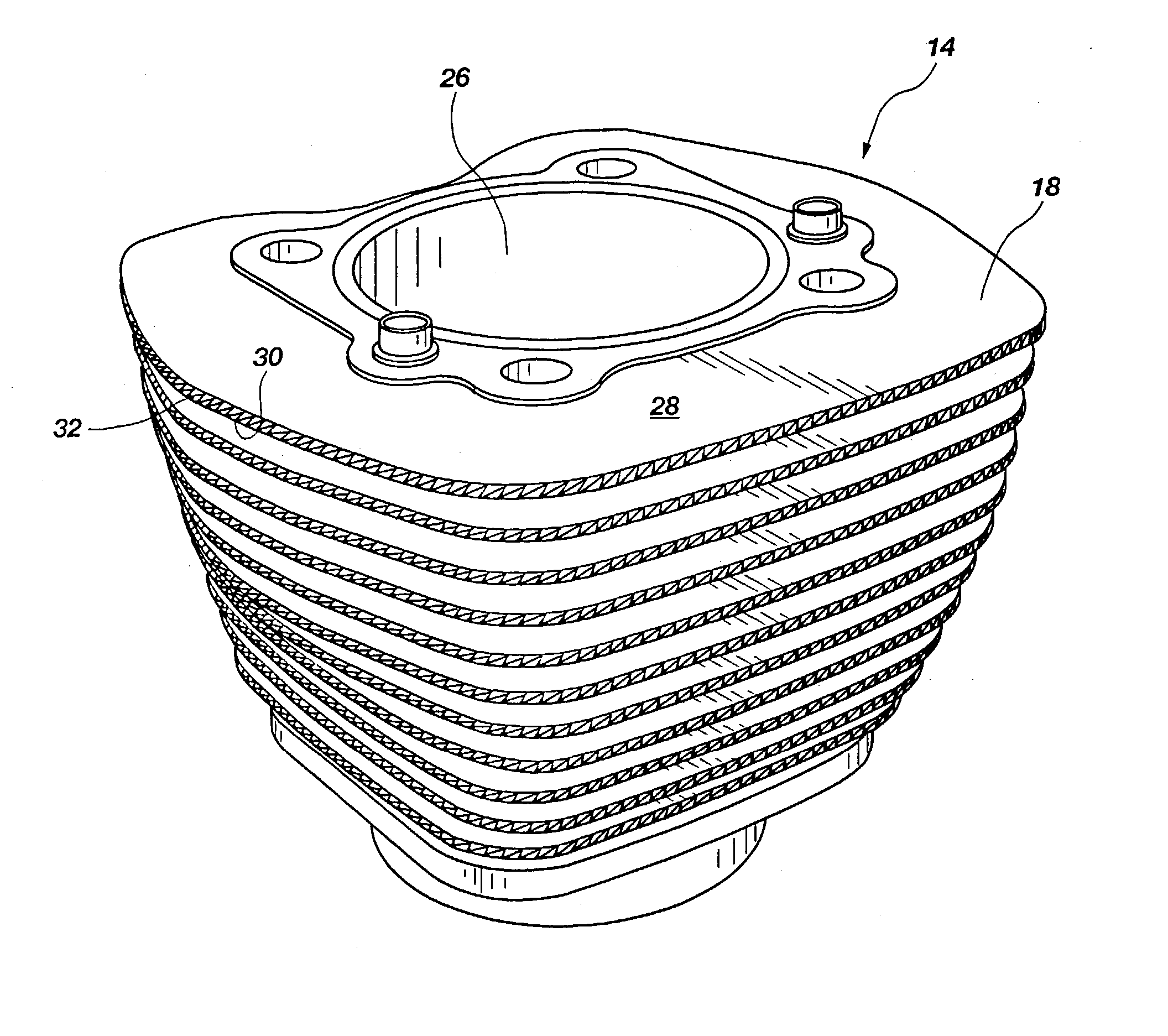

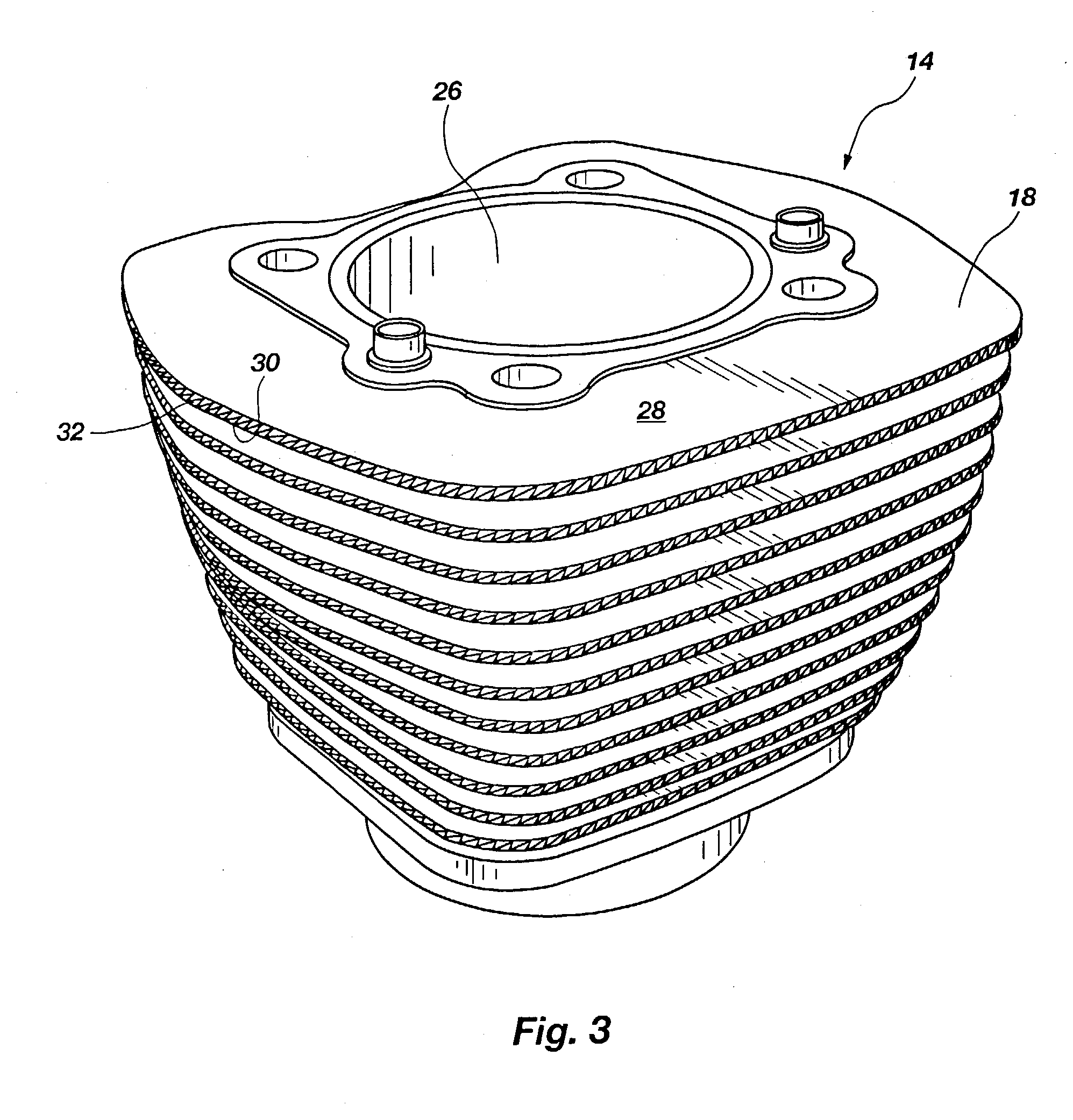

[0056] A cylinder, having an individual displacement of 670 cc, and an attached cylinder head of a V-twin motorcycle engine having a total displacement of 1340 cc was tested. The upright edges of the cylinder as well as the upright edges of the cylinder head exhibited were configured according to the preferred embodiment of the instant invention as shown in FIGS. 19-24, i.e. the upright edges were engraved to define a plurality of elongate concavities. Each of the concavities was oriented with its longitudinal axis at an acute angle to the longitudinal axis of the surface of the edge. The edges were fitted with Omega K-type thermocouples. The thermocouples were attached to the edges with high thermal conductive adhesive. The thermocouples were attached to the 7.sup.th fin and the 13.sup.th fin at mid span on the rear of the cylinder and cylinder head arrangement. A thermocouple was also attached to the 13.sup.th fin on the right side of the arrangement, in a central region of the ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com