Snow board brake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

:

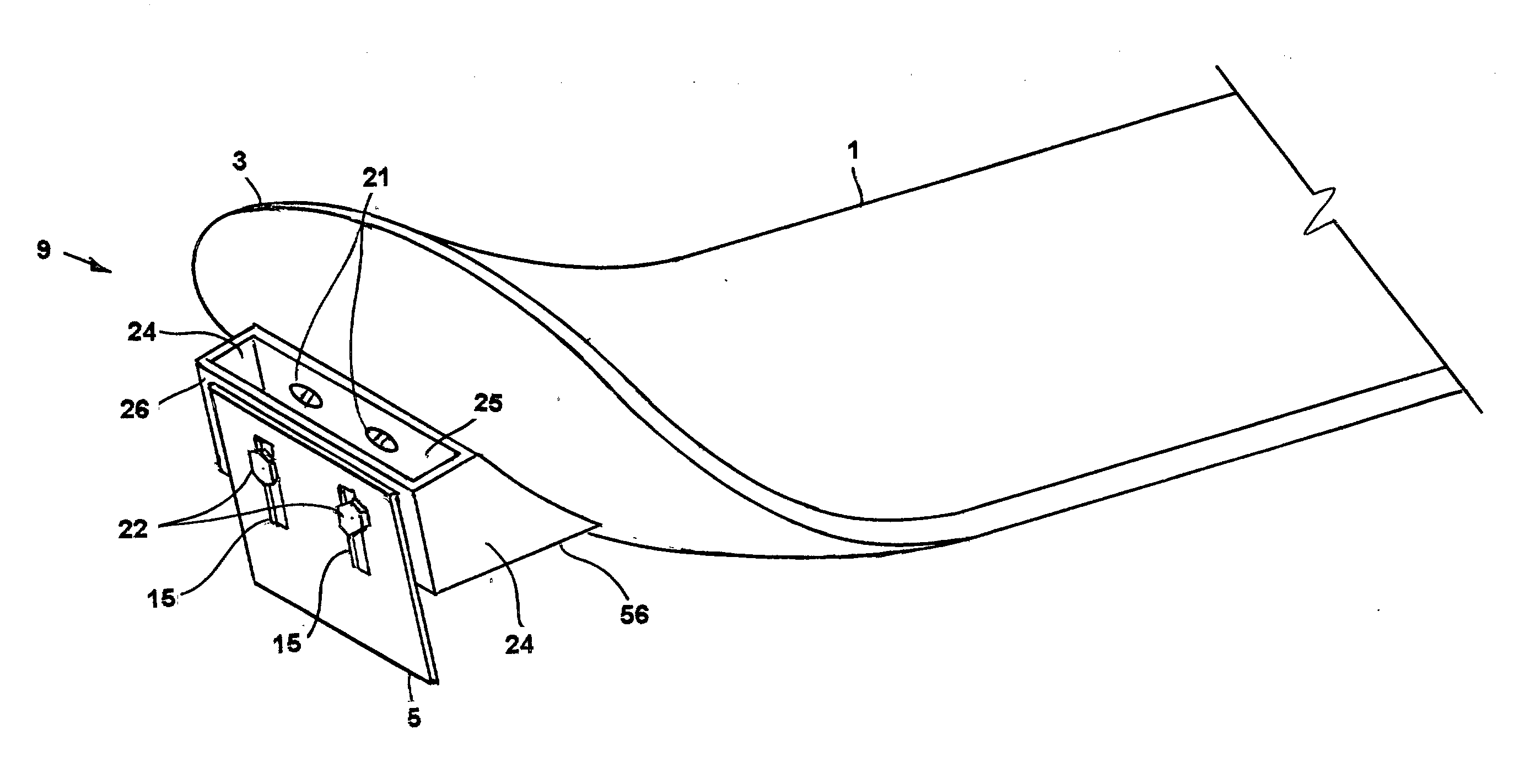

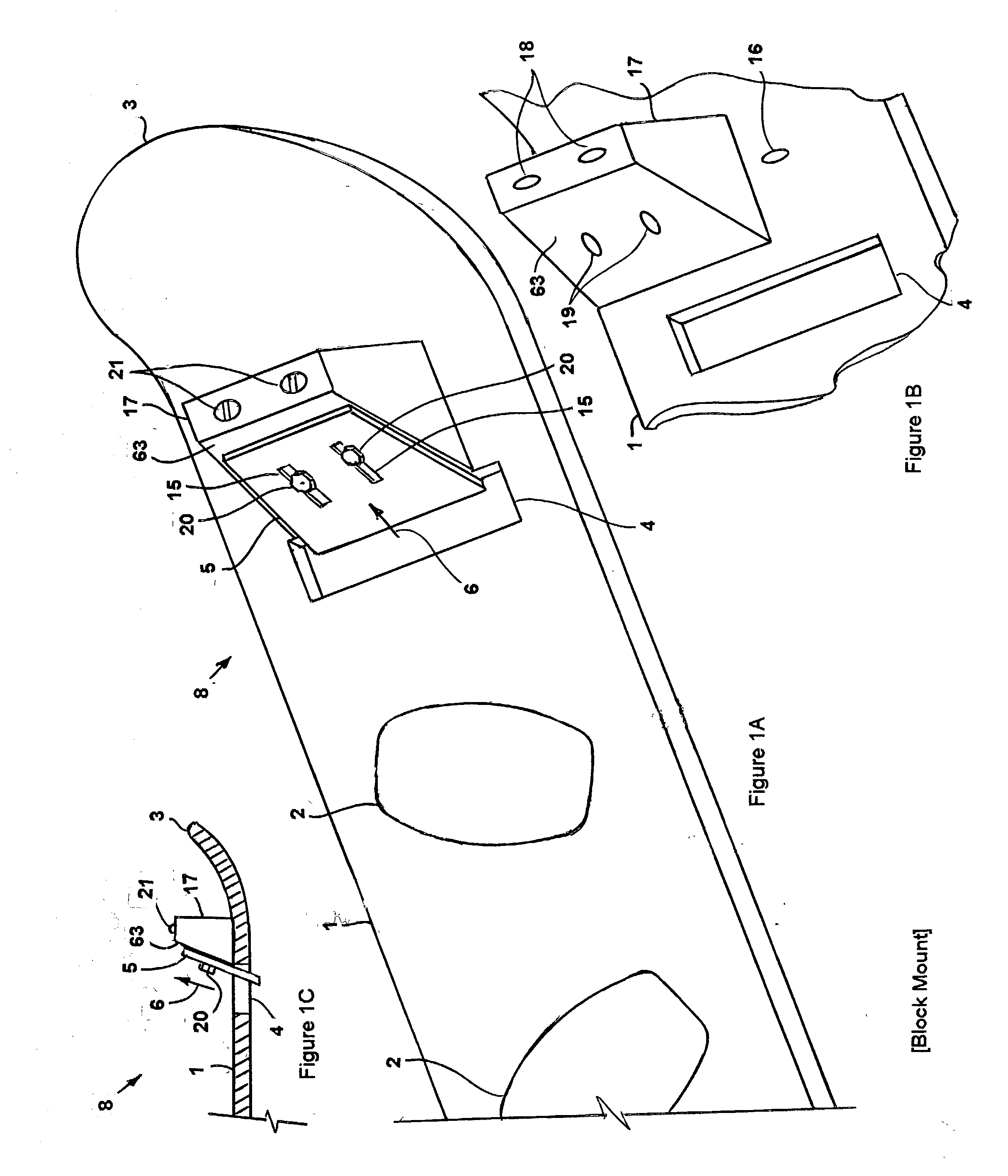

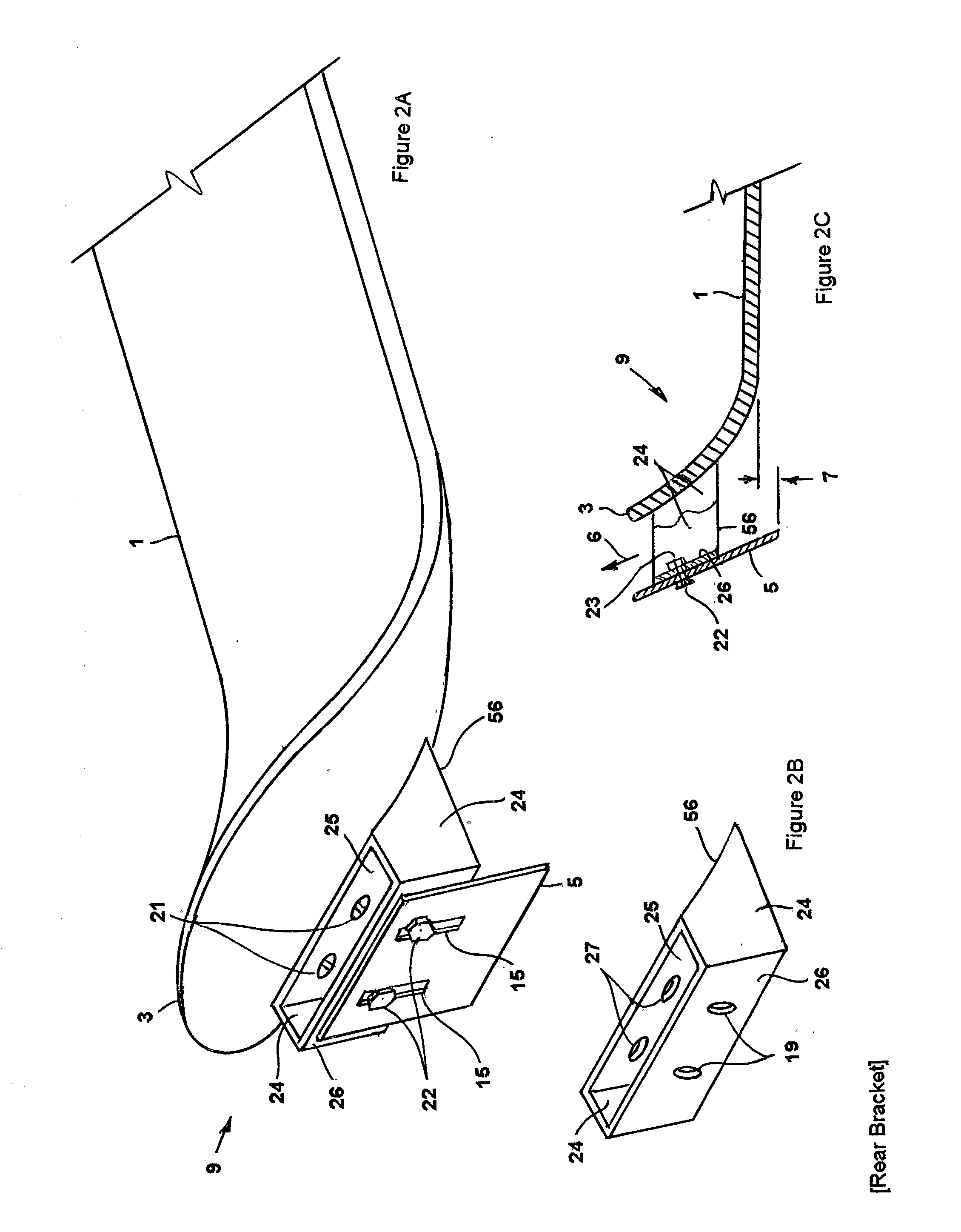

[0052] FIG. 1A presents a perspective view of a snow board, indicated by the general reference number 1, schematic representation of the outline of a pair of boot clamps 2 affixed to the upper surface of said snow board 1 along the center line of said snow board 1, said boot clamps 2 oriented to one side of said snow board 1 and oriented slightly apart from each other. The braking devices 8, 9, 10, 11, 12, 13, 14, 48, 51 are positioned rearward of the noted bindings 2. In the preferred embodiment of the present invention, the braking member is a blade 5 which, when fully extended downward, is oriented straight down or is inclined downward and forward, said blade 5 extends downward by about 1 / 2 inch or less and extends about 4 inches across the middle of the rear bottom surface or across the middle of the end of said snow board 1.

[0053] Nine embodiments of the present invention are specified as follows:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com