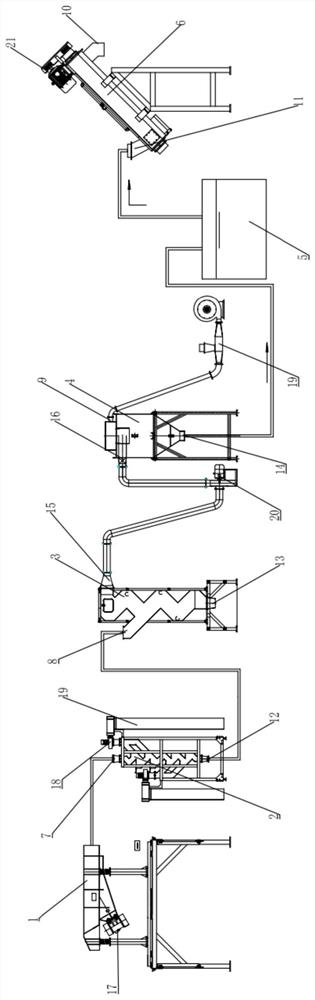

Water-free cleaning method and device for waste plastics

A technology for waterless cleaning and waste plastics, applied in the direction of plastic recycling, recycling technology, etc., can solve the problem of difficult cleaning of waste plastics such as bottles, achieve high added value of products, improve process yield and treatment effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1: HDPE crushed material for cleaning and crushing

[0046] (1) Setting of vibrating feeder 1

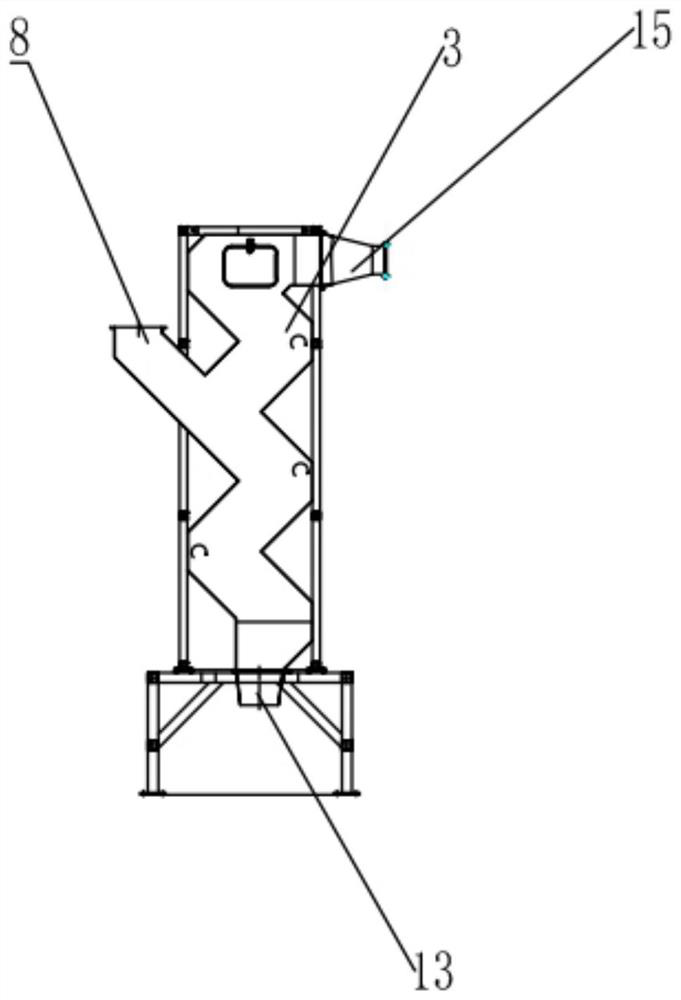

[0047] (2) The wind flux of the primary air separator is 12000m 3 / h

[0048] (3) The wind flux of the secondary air separator is 8000m 3 / h

[0049] (4) Cyclone separator 4

[0050] (5) The soaking time of caustic soda solution pool 5 is 30min

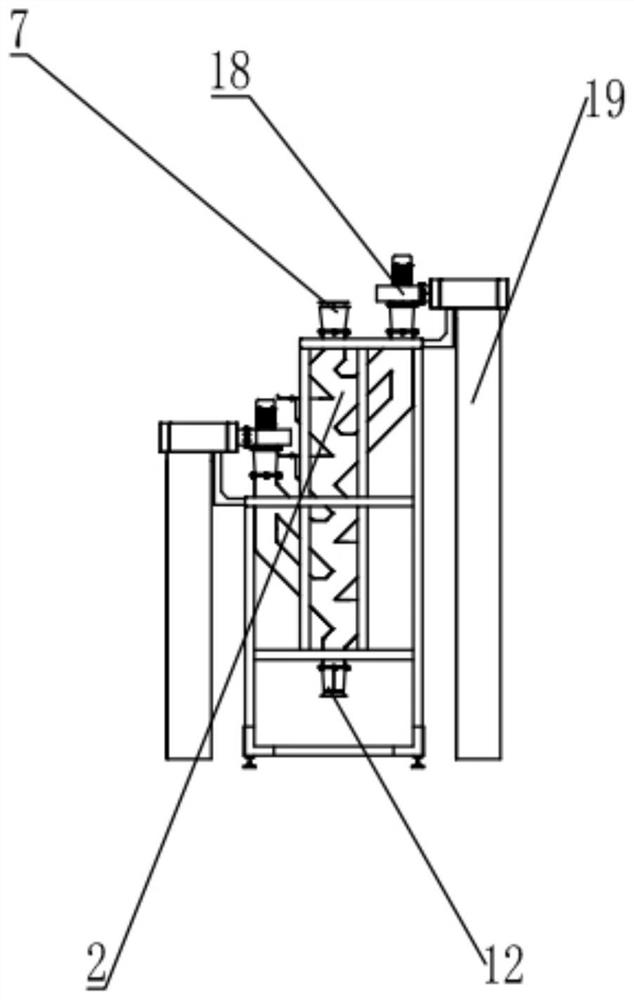

[0051] (6) Friction cleaner 6 size (L*B*H) set 30*10*5m3

Embodiment 2

[0052] Embodiment 2: for cleaning the PET bottle flakes after de-standard and crushing treatment

[0053] Features: Material pollutants are mainly high-adhesion impurities

[0054] (1) Setting of vibrating feeder 1

[0055] (2) The wind flux of the primary air separator is 11000m 3 / h, can not be set

[0056] (3) The wind flux of the secondary air separator is 7000m 3 / h

[0057] (4) Cyclone separator 4

[0058] (5) The soaking time of caustic soda solution pool 5 is 30min

[0059] (6) Friction cleaner 6 size (L*B*H) set 20*10*5m3

Embodiment 3

[0060] Embodiment 3: for the PET bottle flakes after uncleaned de-labeling and crushing treatment

[0061] Features: There are many impurities in the label paper

[0062] (1) Setting of vibrating feeder 1

[0063] (2) The wind flux of the primary air separator is 12500m 3 / h

[0064] (3) The wind flux of the secondary air separator is 11000m 3 / h

[0065] (4) Cyclone separator 4

[0066] (5) The soaking time of caustic soda solution pool 5 is 30min

[0067] (6) Friction cleaner 6 size (L*B*H) set 20*10*5m3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com