Colorless glasses/borosilicate glasses with special UV-edge

a borosilicate glass, colorless technology, applied in the direction of optics, instruments, optical elements, etc., can solve the problems of affecting the solarization effect of the glass, the glass type is not suitable for commercial application cases, and the material cost of the glass is significantly increased

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

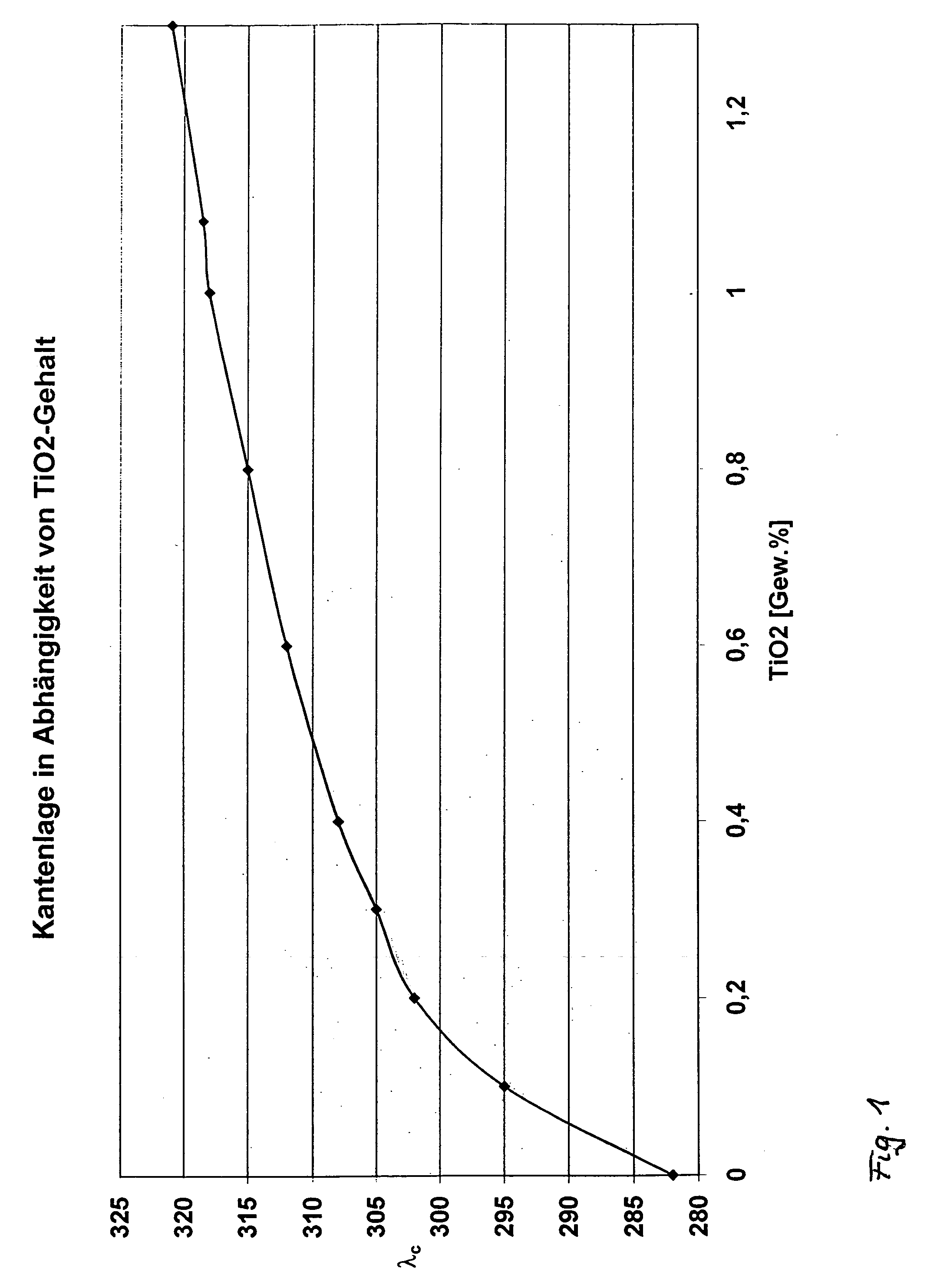

Image

Examples

Embodiment Construction

[0032] Normal optical raw materials are used for producing the exemplary embodiments of glasses.

[0033] The well homogenized glass batch was melted, refined and homogenized in the laboratory in a Pt crucible at 1420.degree. C. Subsequently the glass was cast and cooled at 20 K / h.

1TABLE 1 shows a melt example of a 0.51 melt: Oxides % by weight Raw material Initial weight (g) SiO.sub.2 69.98 SiO.sub.2 772.65 B.sub.2O.sub.3 11.19 H.sub.3BO.sub.3 219.5 Na.sub.2O 9.49 NaNO.sub.3 287.79 K.sub.2O 7.29 3.8 K.sub.2CO.sub.3 61.69 3.49 KNO.sub.3 82.78 CaO 0.2 CaCO.sub.3 3.94 BaO 1.35 Ba(NO.sub.3).sub.2 25.38 TiO.sub.2 0.20 TiO.sub.2 2.22 Sb.sub.2O.sub.3 0.30 Sb.sub.2O.sub.3 3.31

[0034] The properties of the thus obtained glass are indicated in Table 2, Example 3.

2TABLE 2 shows 9 examples of glasses according to the invention (1 to 9) with their compositions (in % by weight on an oxide basis) and their essential properties: Example No. Oxides 1 2 3 4 5 6 7 8 9 B.sub.2O.sub.3 11.21 11.20 11.19 11....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com