Method and apparatus for precast and framed block element construction

a prefabricated and framed block technology, applied in the field of building systems, can solve the problems of affecting the construction efficiency of the building, the inability to meet the requirements of the construction period,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

--Precast and Framed Construction Blocks

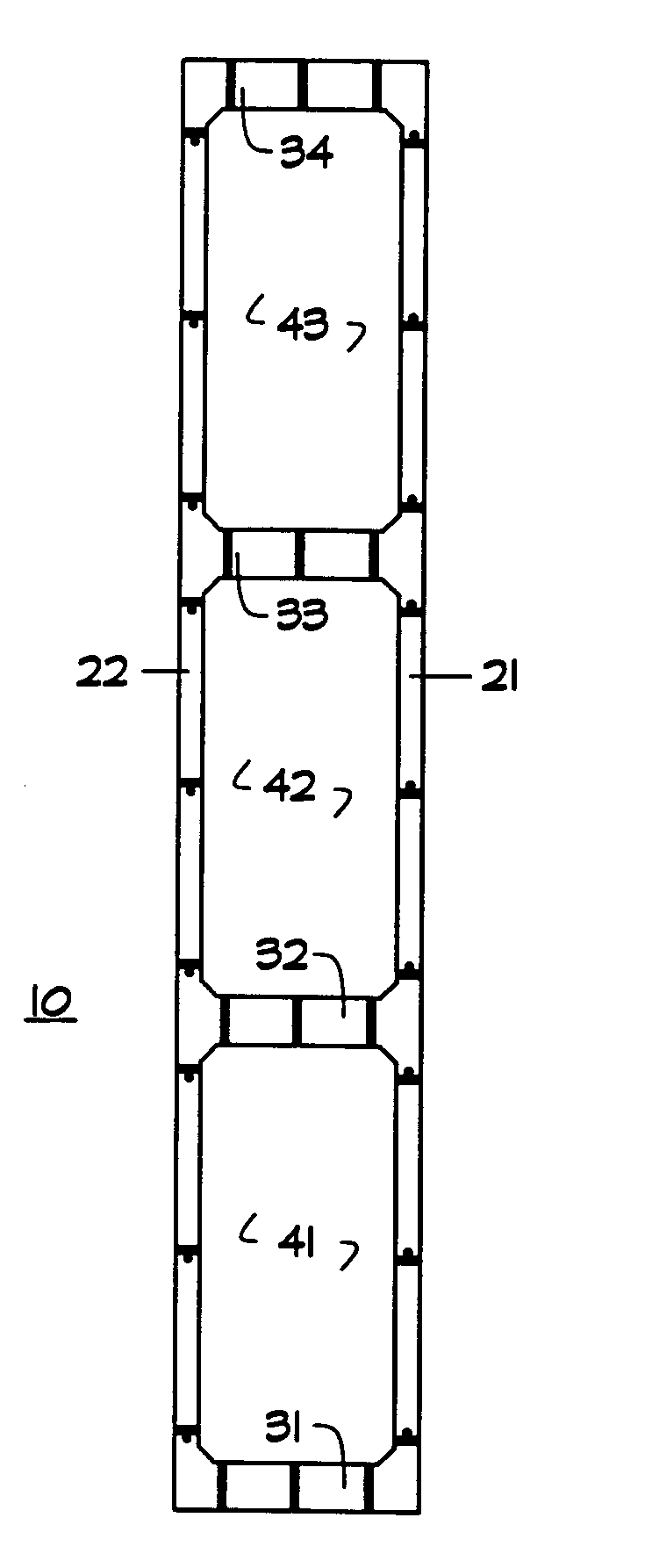

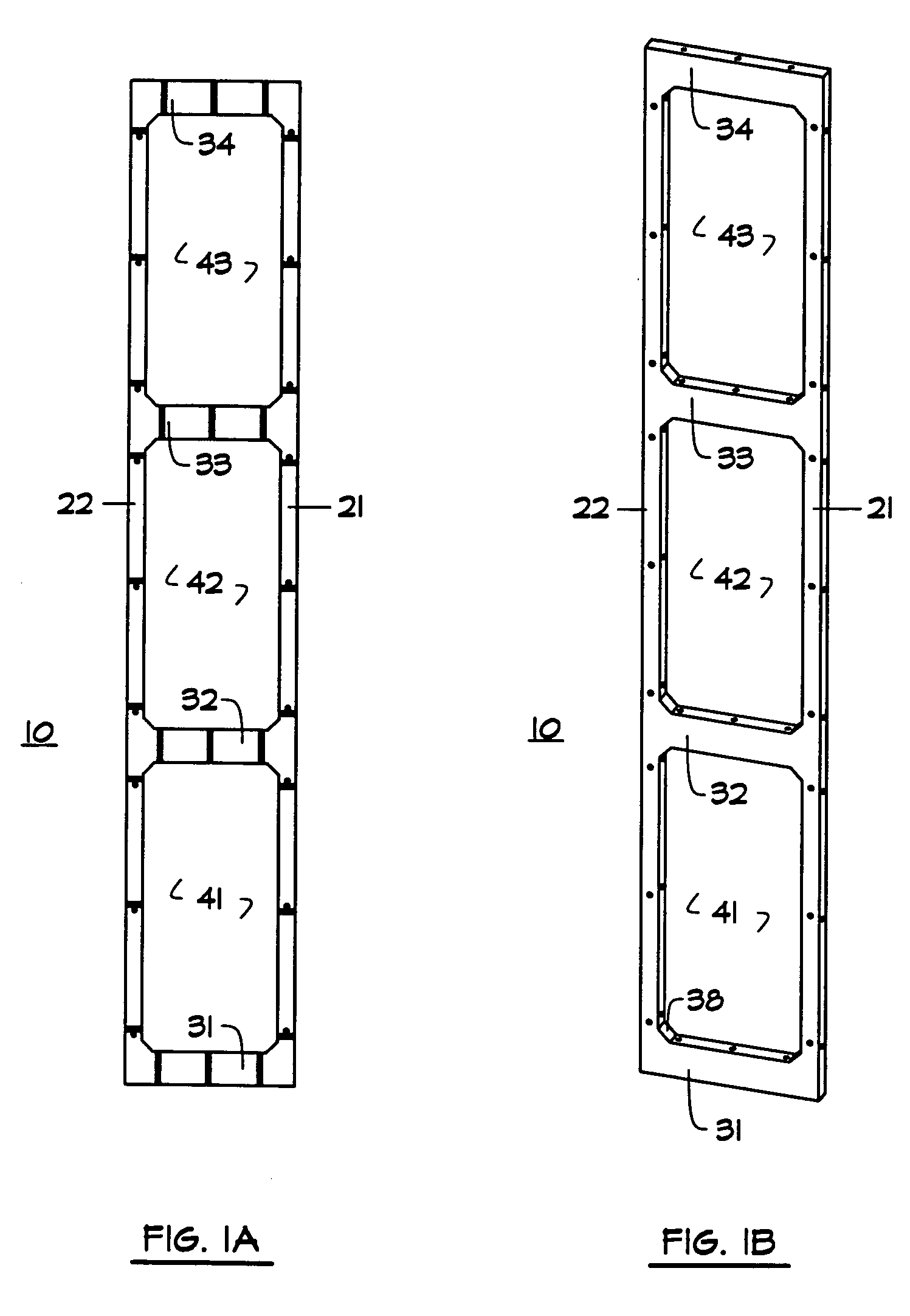

[0108] A basic block of one embodiment of the invention is shown in FIG. 1A and FIG. 1B which are an elevation and isometric view of a single block. It is from the geometry of this most basic block of the building system that LadderBlock.TM. derives its name. The block 10 shown is 5 feet wide, 30 feet tall, and 6 inches thick, with two edge chords 21 and 22, and three vertical openings 41-43 defined by beam sections 31-34. This block is referred to as a three-story block in this discussion. In one example, reinforced concrete chord sections of this embodiment are 6" wide by 6" thick, and beam sections are 12" deep by 6" thick. The block overall geometry, dimensions, number of openings, cross-sectional dimensions and reinforcement may each be adjusted within practical limits for a specific application.

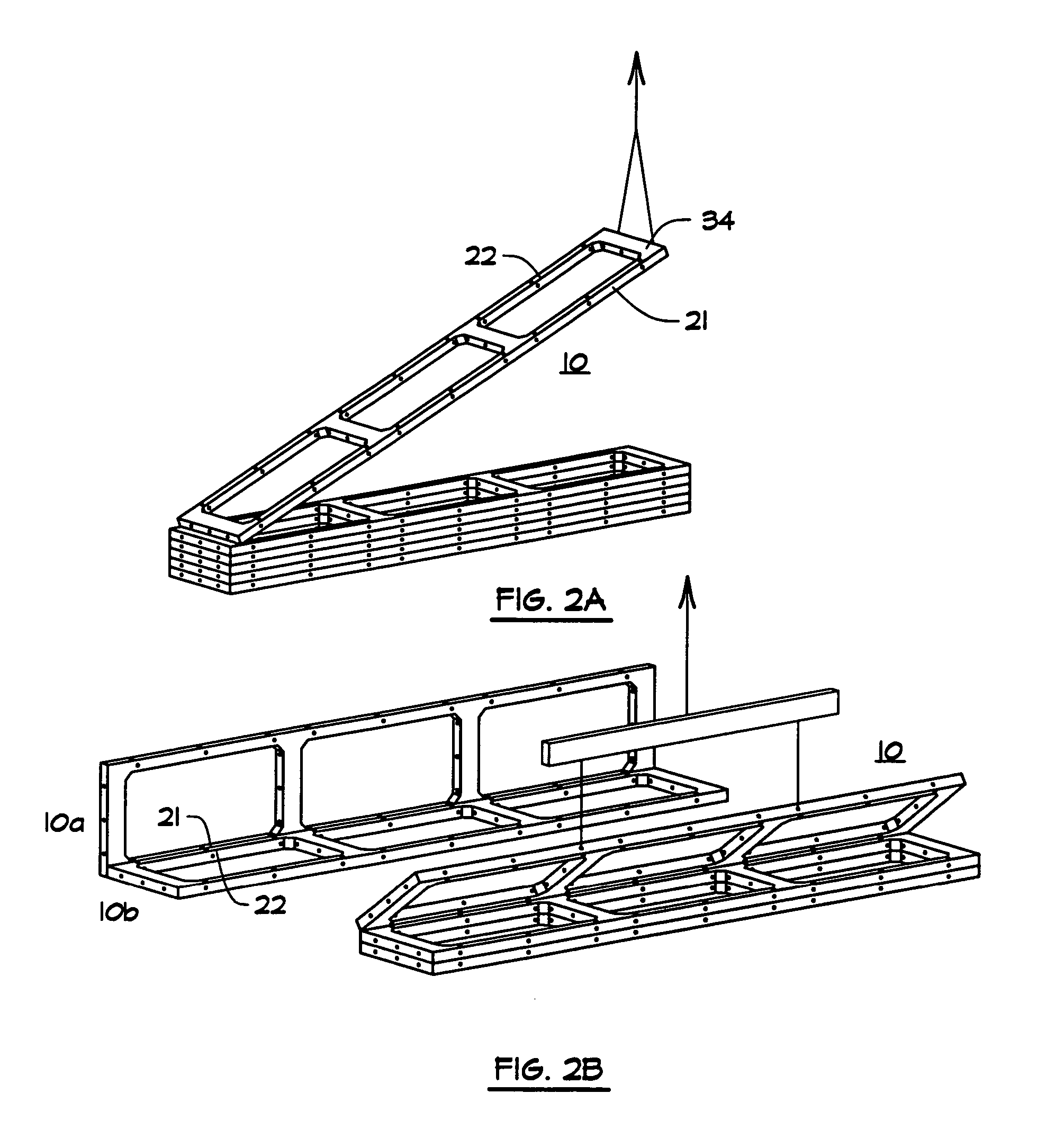

[0109] The design of this system is intended to allow the rapid replication of identical high-quality building blocks to serve as large-scale bui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thick | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com