Spraygun with built-in quick-fit connector

a quick-fit, gun technology, applied in couplings, transportation and packaging, drawing-off water installations, etc., can solve the problems of increased costs, unusable guns, and damaged threads on guns and pots,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

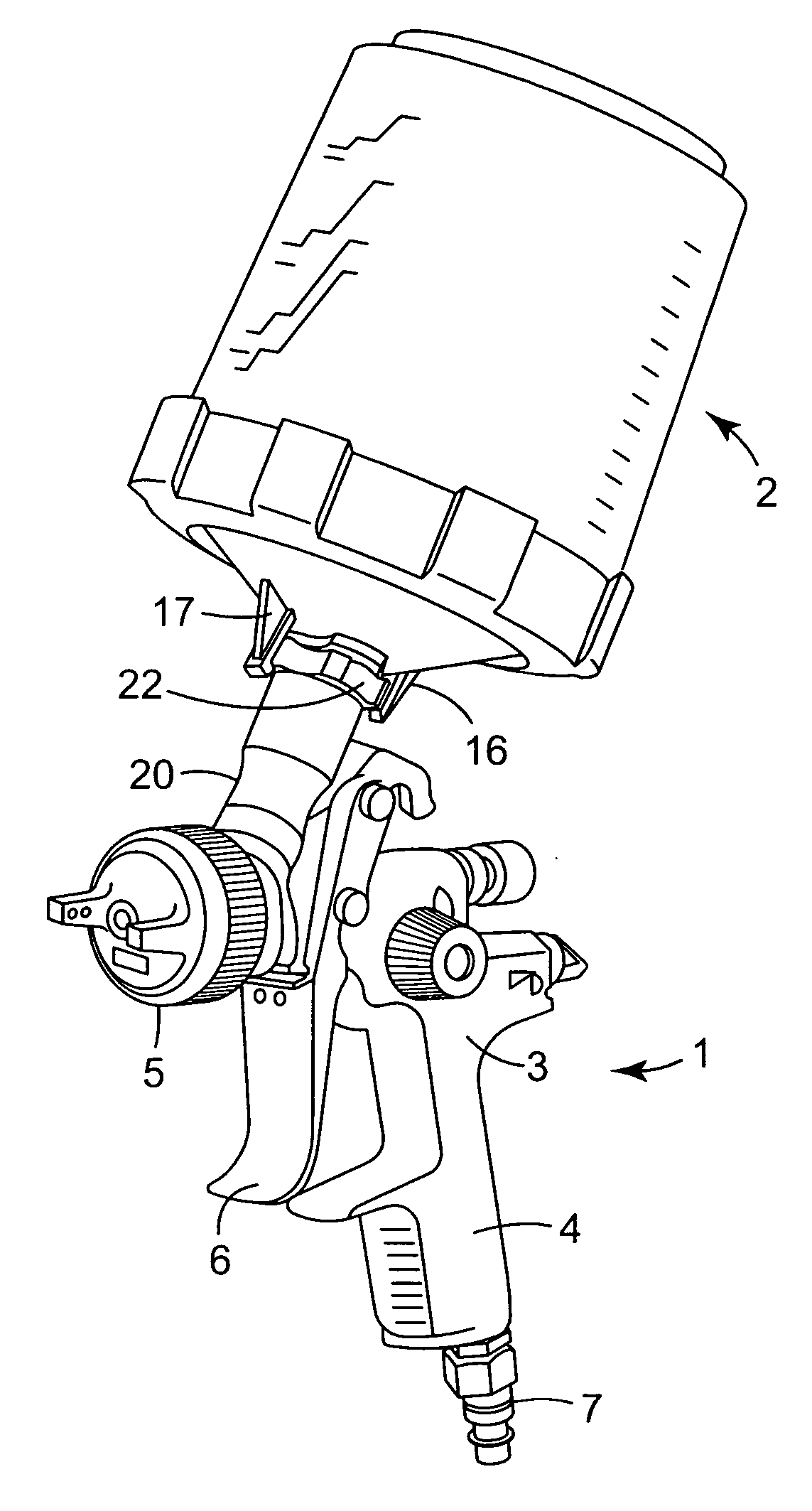

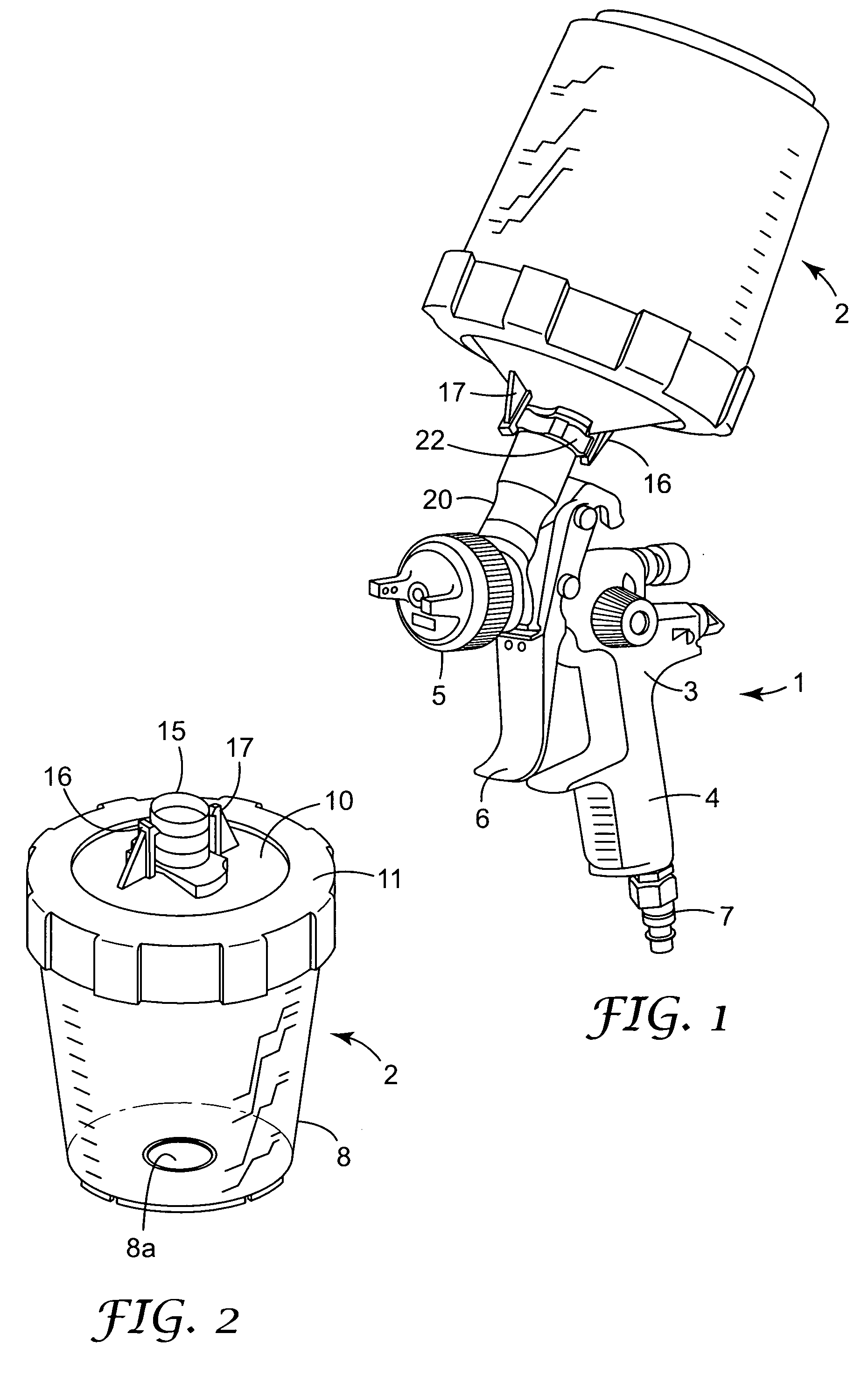

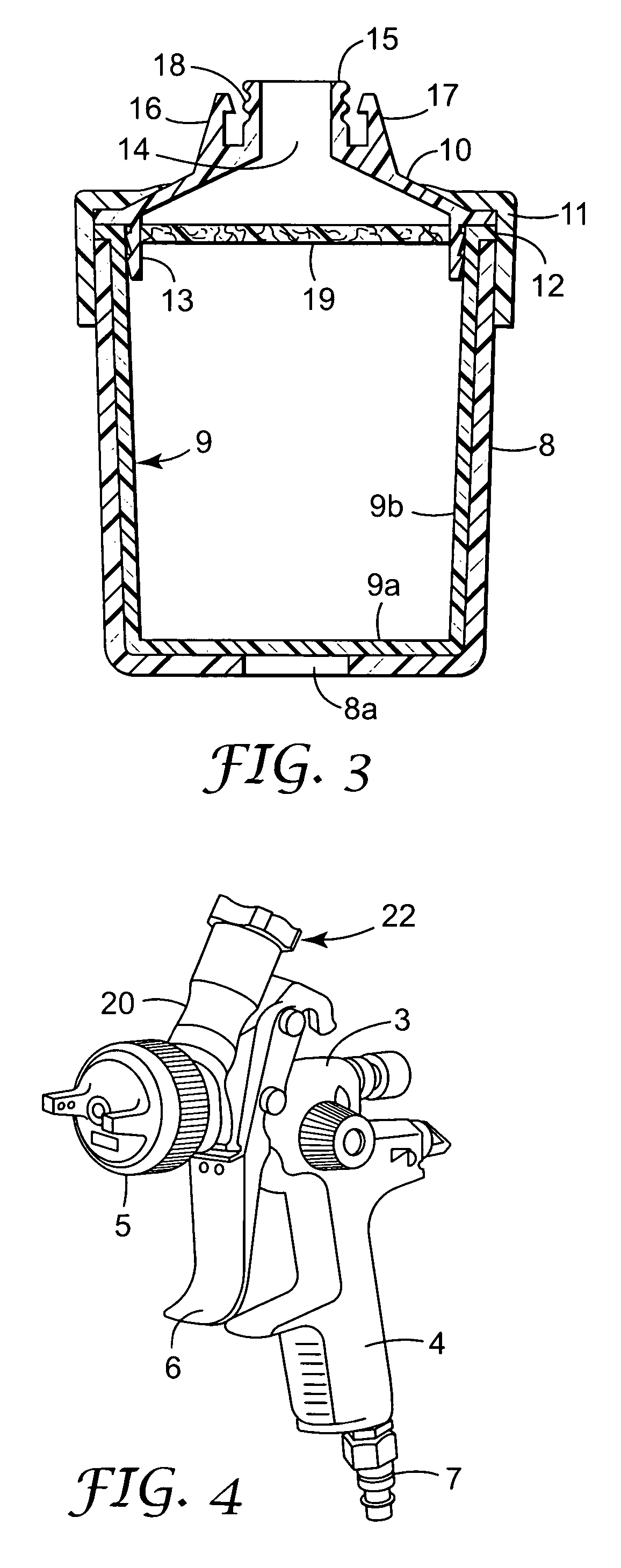

[0122] Referring first to FIG. 1 of the accompanying drawings, there is shown liquid spraying apparatus embodying the present invention comprising a gravity fed spray gun 1 and a reservoir 2 releasably connected to the spray gun 1.

[0123] The gun 1 comprises a body 3, a handle 4 which extends downwards from the rear end of the body, and a spray nozzle 5 at the front end of the body. The gun 1 is manually-operated by a trigger 6 which is pivotally-mounted on the sides of the gun.

[0124] The reservoir 2, which contains paint (or similar material) to be discharged by the gun, is located on the top of the body 3 and communicates with an internal passageway (not visible) which extends through the gun to the nozzle 5.

[0125] In use, the gun 1 is connected via a connector 7 at the lower end of the handle 4 to a source of compressed air (not shown) so that, when the user pulls on the trigger 6, compressed air is delivered through the gun to the nozzle 5. As a result, paint delivered under grav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com