Golf clubhead for putting or striking a golf ball

a golf club and golf ball technology, applied in the field of golf club heads, can solve the problems of loss of a stroke, misdirection of the ball and an impact force other than anticipated, and achieve the effect of only partially effective solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The specifications herein describe a putter clubhead. Description of iron and metalwood clubheads will be described in the alternative embodiments section.

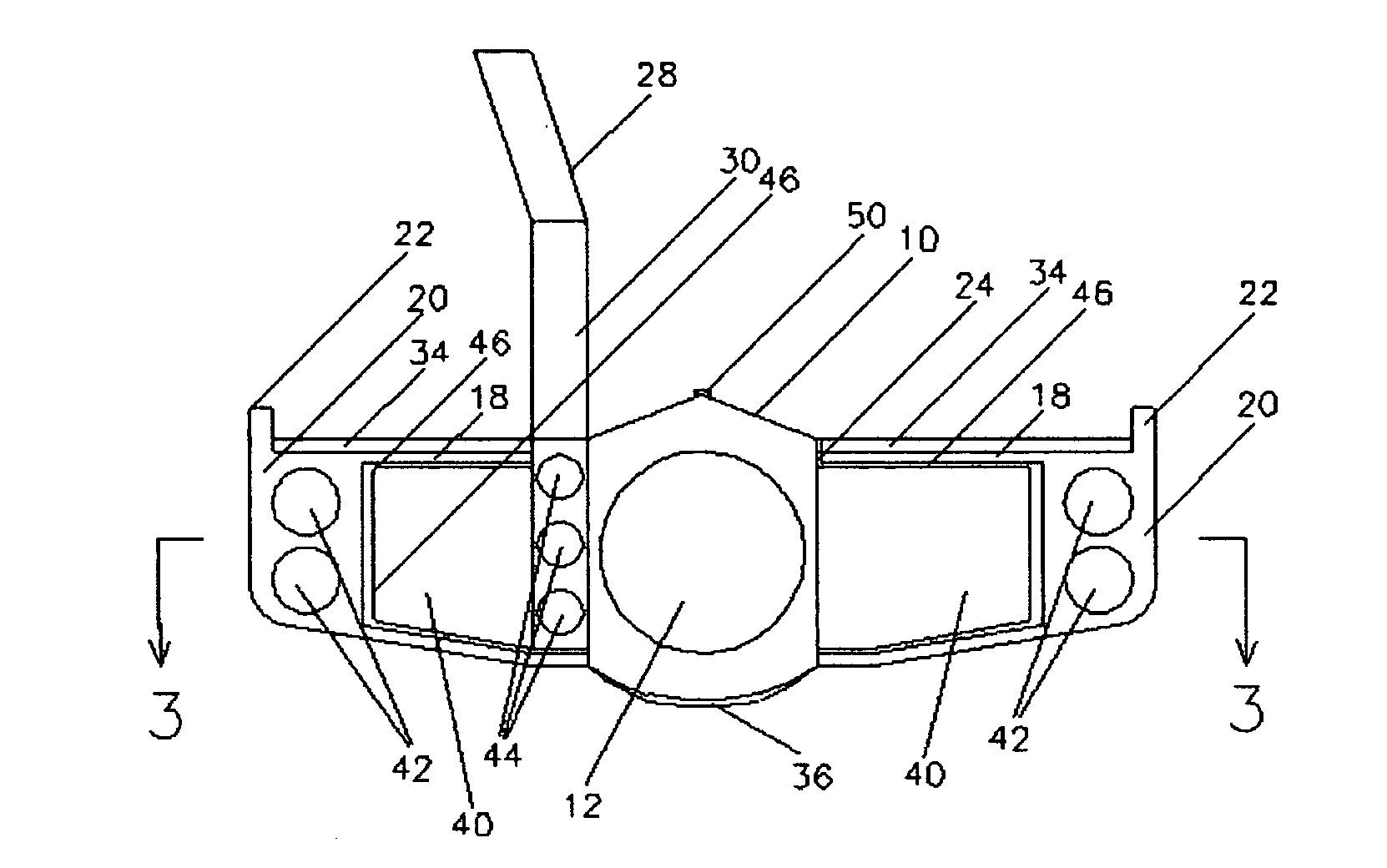

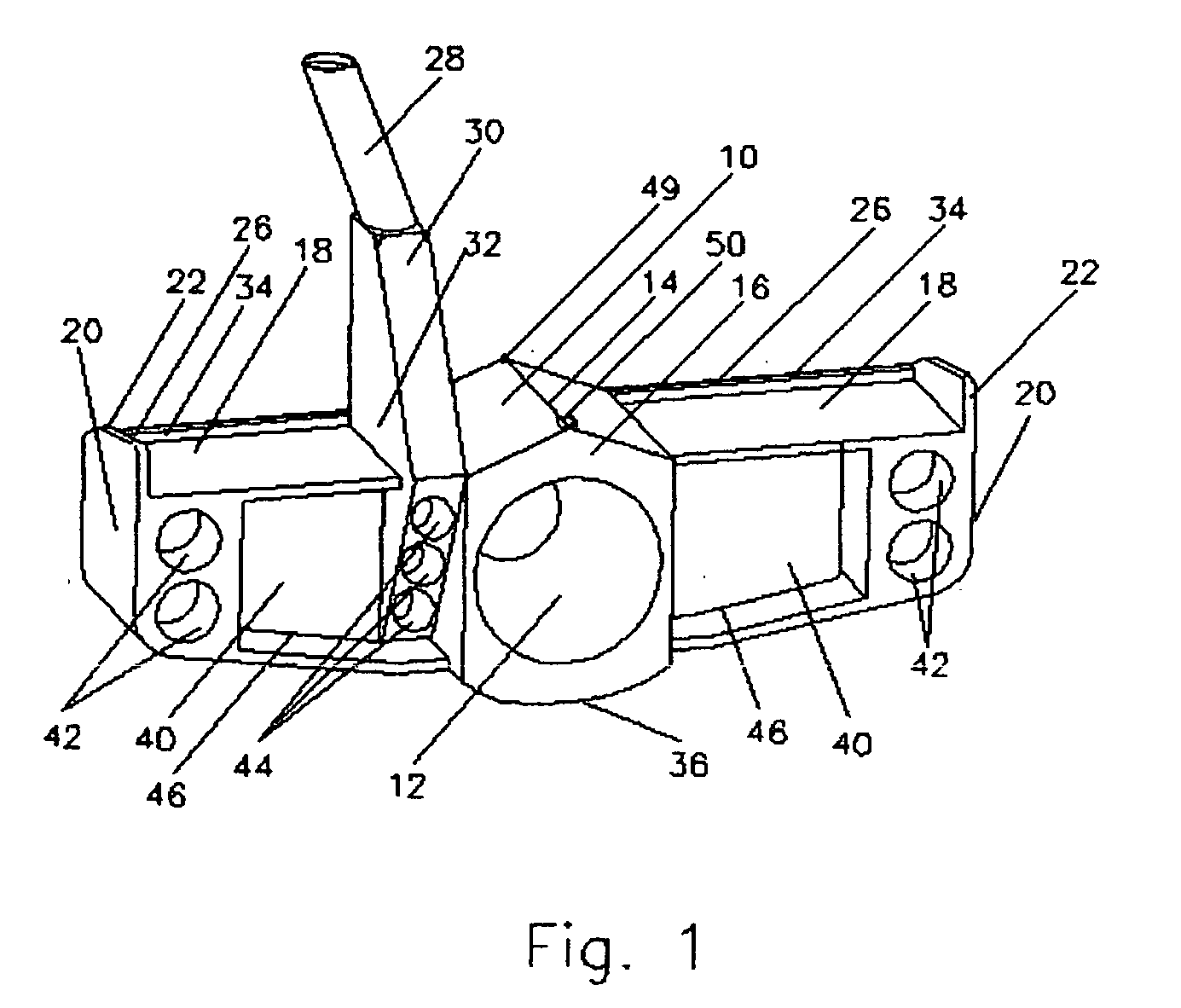

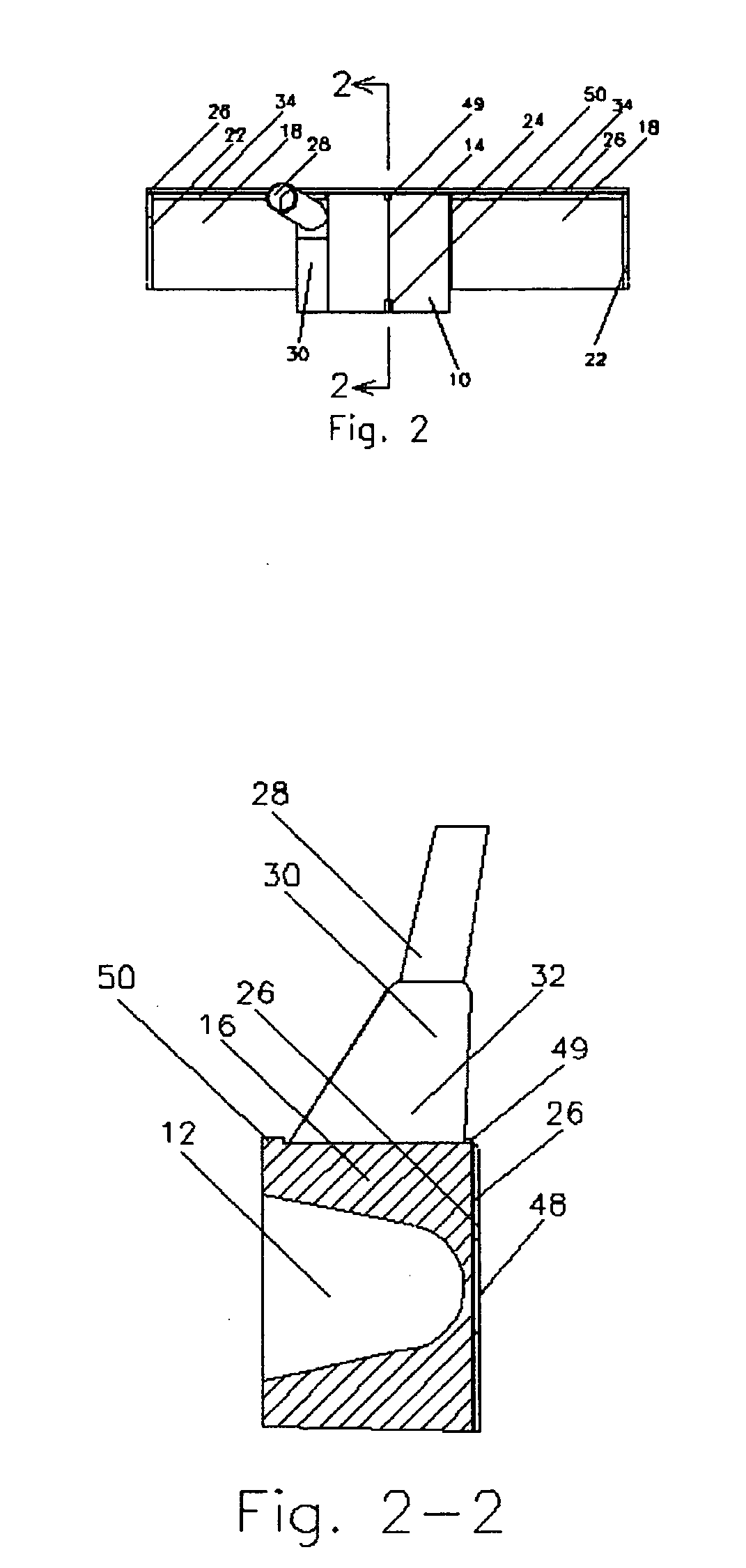

[0060] FIG. 1 shows the rear perspective view from the heel-side of the preferred embodiment of the present invention. My putter clubhead consists of a hollowed tubular shape similar to an abbreviated six-sided gun barrel, named a strike-barrel 10. Clubhead sole 36 is the rounded and somewhat flattened bottom side of strike-barrel 10. Strike barrel 10 is opened from the rear to near the very front of clubhead to create strike-barrel pocket 12. Arms 18 sandwich strike-barrel, which more or less constitutes the center portion of the clubhead. Arm pockets are the openings of each arm from the rear. Hosel 30 is somewhat triangular in shape and connects the shaft 28 to clubhead. The lower portion of hosel 30 contains pockets 44 which are open-ended from the rear. Without hosel 30, the clubhead is generally symmetrical from heel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com