Temperature measuring method and apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

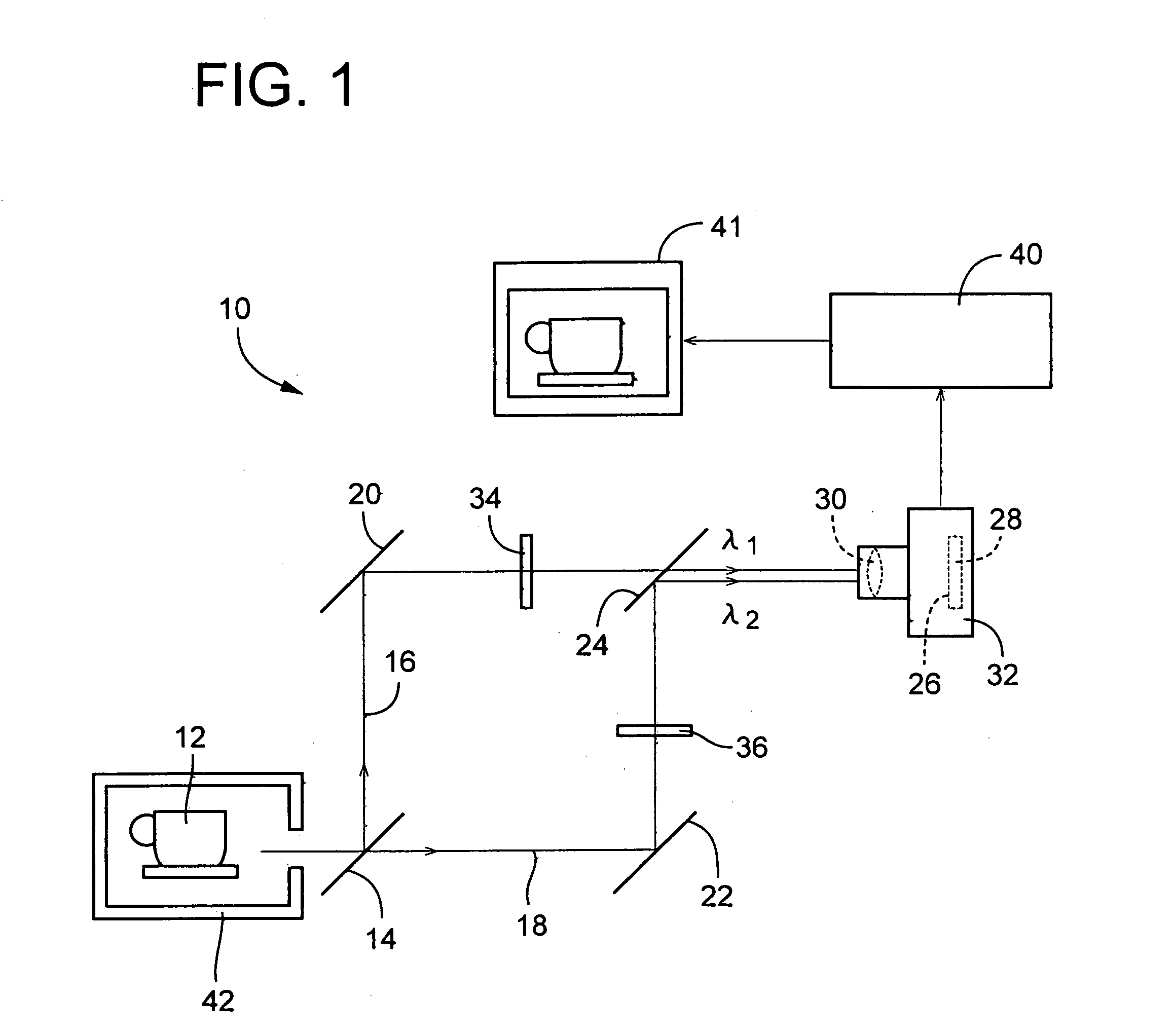

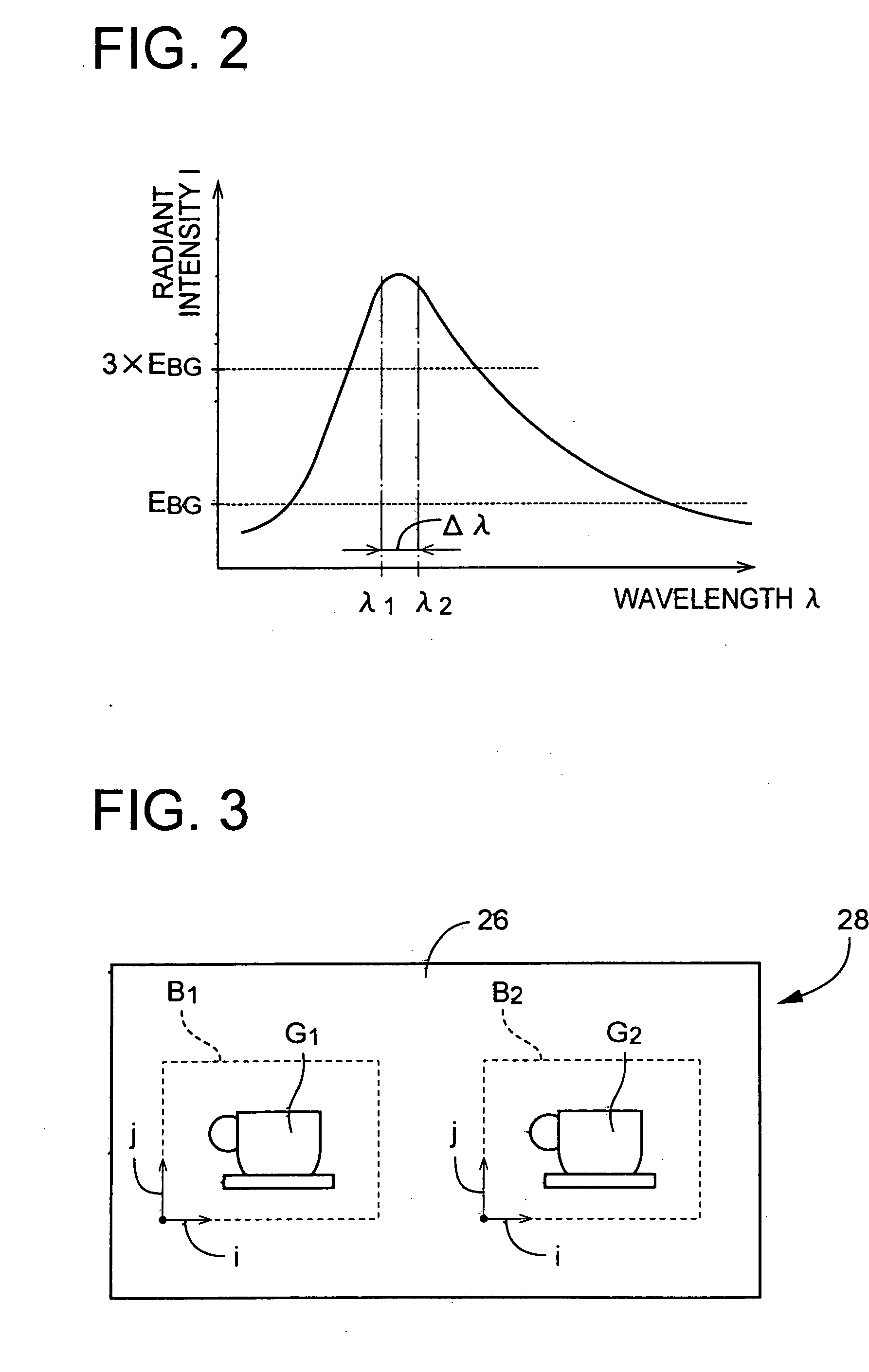

[0047] Referring first to FIG. 1, there is shown an arrangement of a temperature-distribution measuring apparatus 10 as this invention, wherein a light emitted or radiated from a surface of an object body 12 in a firing furnace or a heating furnace in the form of an electric furnace 42 is split by a half mirror (beam splitter) 14 into a first component traveling along a first optical path 16 and a second component traveling along a second optical path 18. The first and second optical paths 16, 18 are bent substantially at right angles by respective mirrors 20, 22, so that the first and second components are both incident upon a half mirror 24, and are reflected by the half mirror 24, so as to be incident upon an image detector 32 which has a CCD device 28 and a lens device 30. The CCD device 28 has a light detecting surface 26 on which are arranged a multiplicity of photosensitive elements. The lens device 30 is arranged to focus images of the object body 12 on the light detecting s...

second embodiment

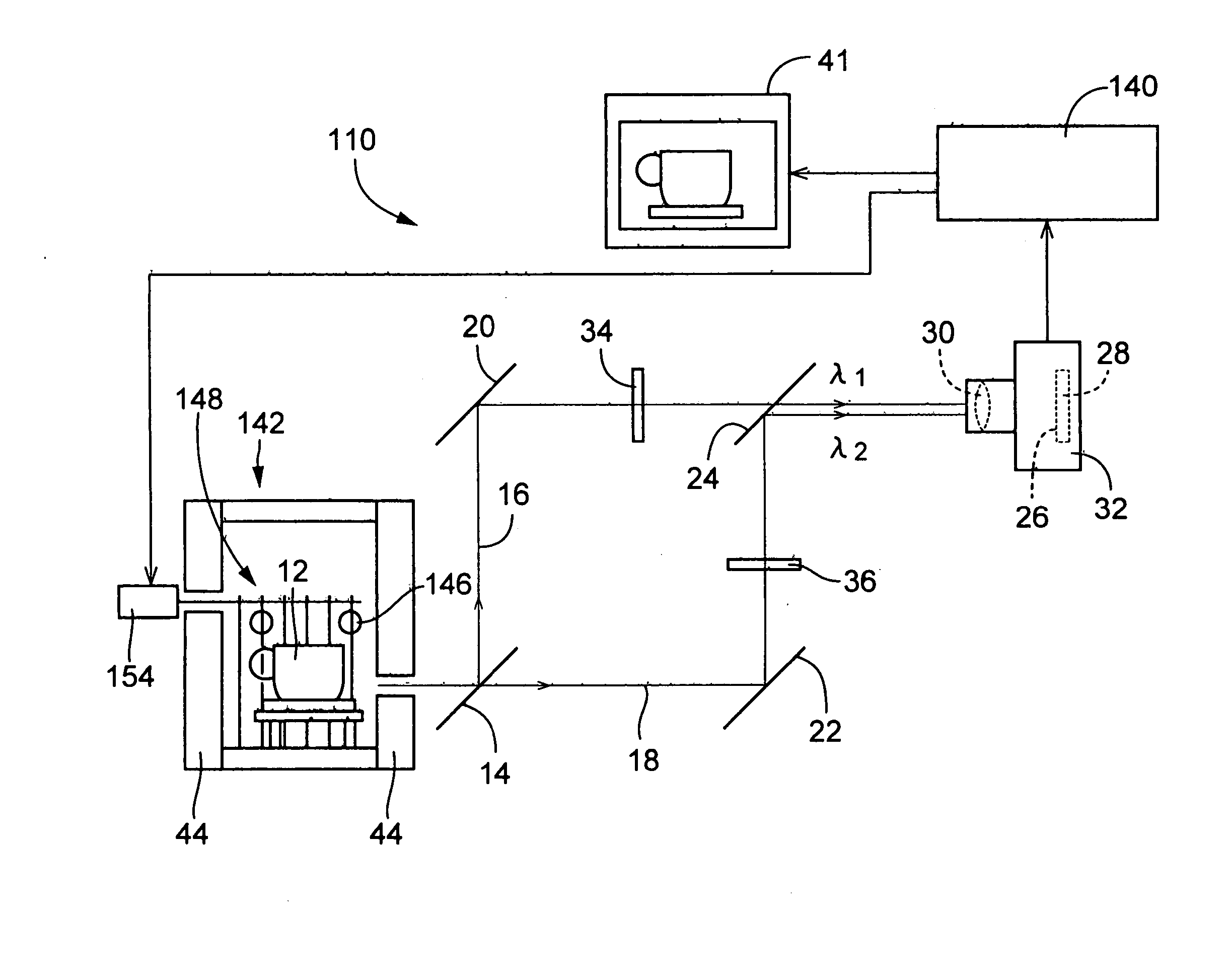

[0078] As described above, the present invention is arranged such that: the object body 12 is heated in the heating step, while the shielding device disposed between the side furnace walls 44 of the heating furnace 142 and the object body 12 is in its open state; the intensity of the radiant energy emitted from the object body 12 is detected in step S12 corresponding to the radiant-energy detecting step or means, while the shielding device 148 is closed; and the temperature at each picture element of the image of the object body 12 is calculated in the step S15 corresponding to the temperature calculating step or means, based on the intensity of the radiant energy emitted from the object body 12 as detected in the step S12. Accordingly, the stray light noise or the intensity of the radiant energy of the stray light, which is emitted from the side furnace walls 44 and the burners 146 toward the object body 12 and reflected by the surface of the object body 12 and which is included in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com