Window box and mounting system

a window box and mounting system technology, applied in the field of windows, can solve the problems of difficult installation, deterioration of window boxes, and system relying on gravity force, and achieve the effect of strong and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

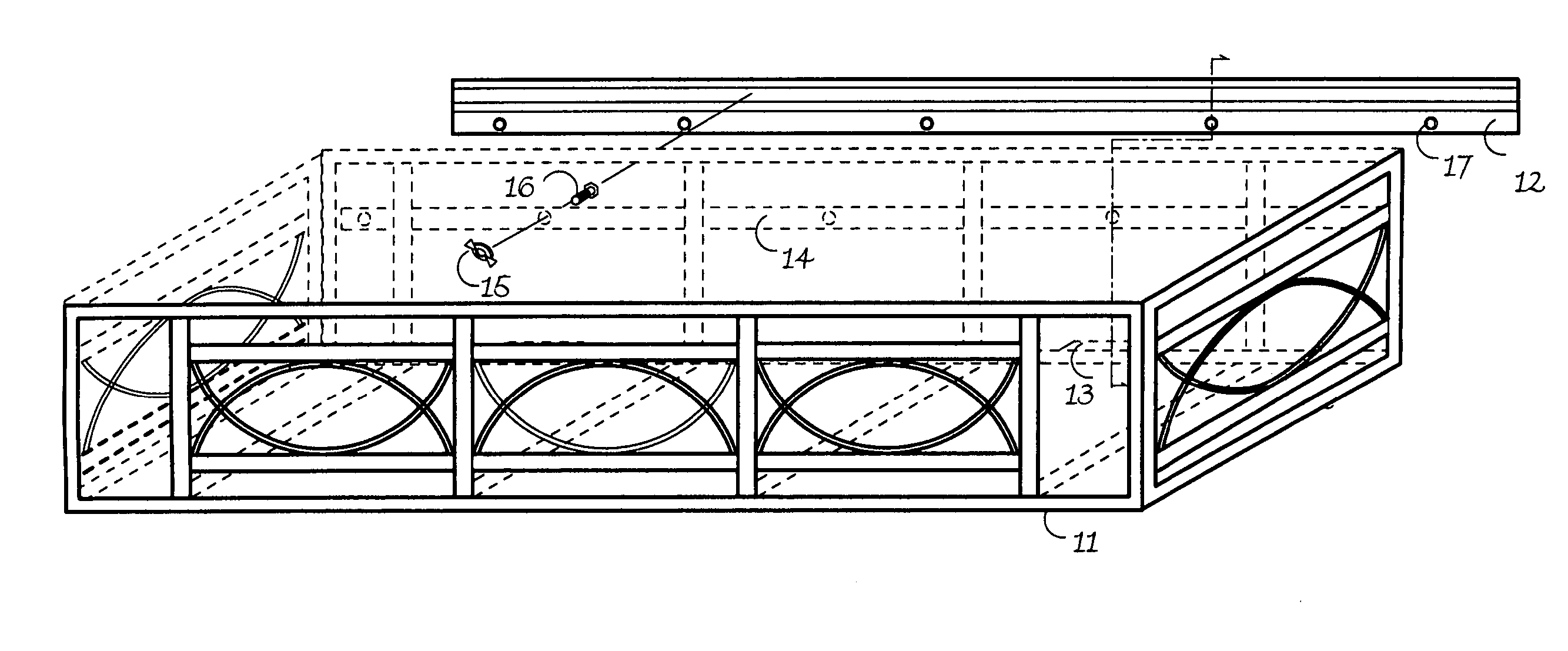

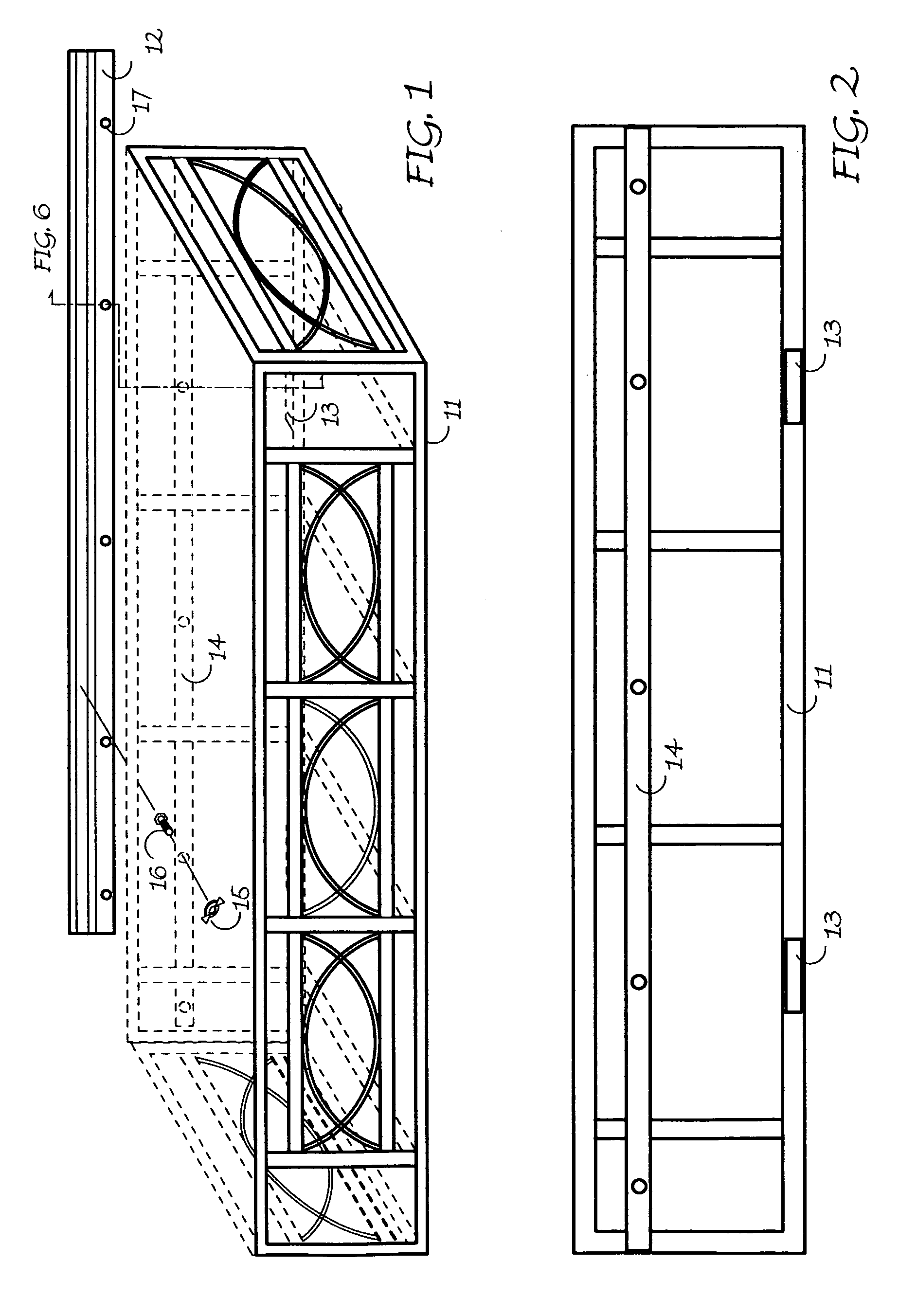

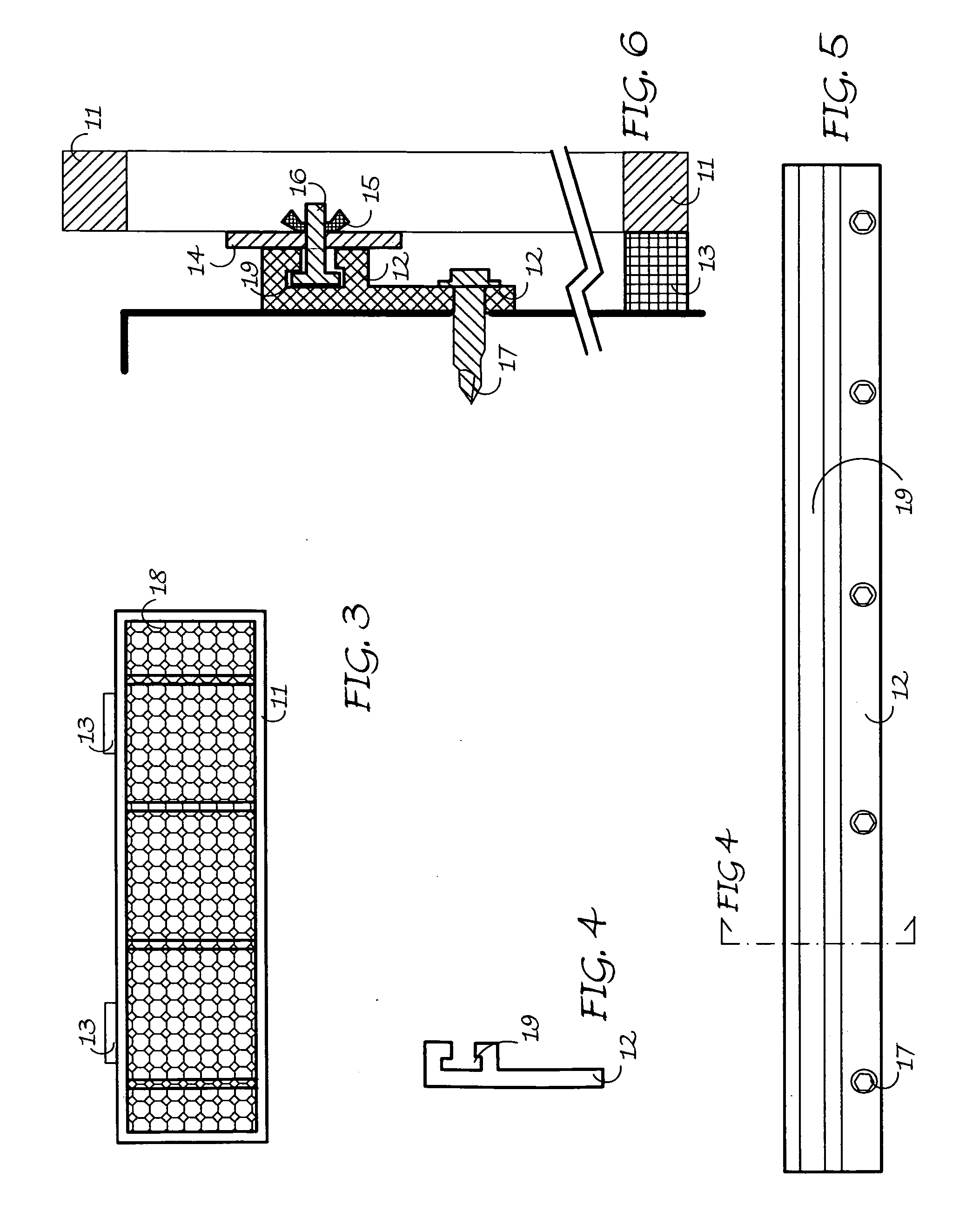

[0026]FIG. 1 is a perspective view taken from the user's right side of the window box 11 and an exploded view of the complete mounting system. The window box 11 in this Fig. is 45 inches in length, however, all dimensions of the window box are for illustrative purposes only, as it is the intention that this mounting system can be used with any size window box or object. The window box 11 can be made of aluminum, although, the material is not the object of this invention as any other material could be used to provide a similar utility. The advantages and reasons for aluminum in the described window box design box 11 is that aluminum does not rust.

[0027]FIG. 1 illustrates that a mounting bar 12 (made of aluminum) is attached using conventional hardware (e.g. TEK screw in masonry) and the window box 11 is then attached to the mounting bar 12 using stainless steel bolts 16 and wing nuts 15 at regular intervals. Also showing (but better illustrated in FIGS. 2 & 6) are two support bars 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com