Furniture fabric and a manufacturing method for yarn of furniture fabric

a manufacturing method and furniture fabric technology, applied in the direction of yarn, continuous wounding machines, weaving, etc., can solve the problems of void of good tension strength, limited color variety, inability to sustain heavy weight, etc., and achieve better support force for heavy weight, good variety of colors, and strong tension strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

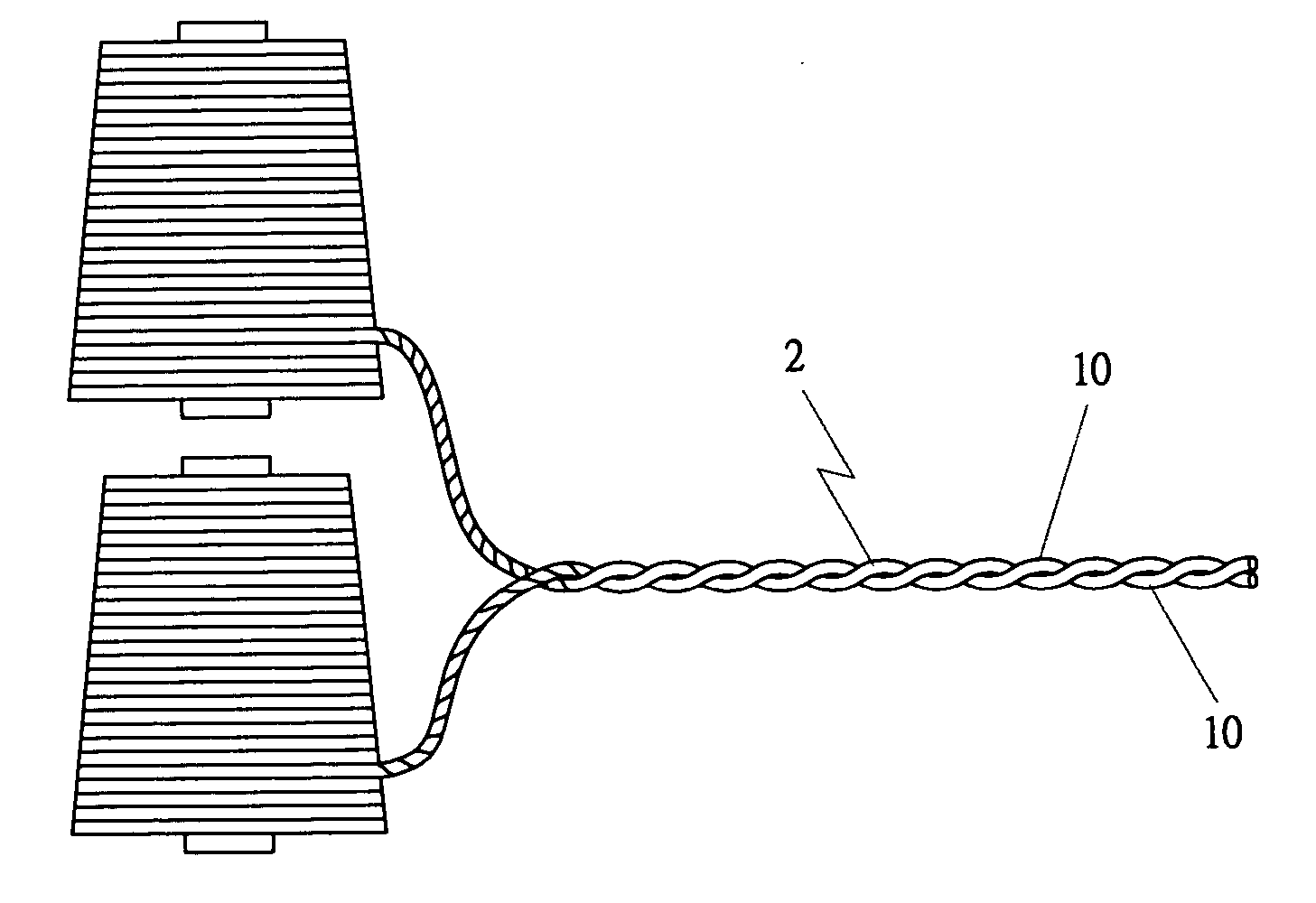

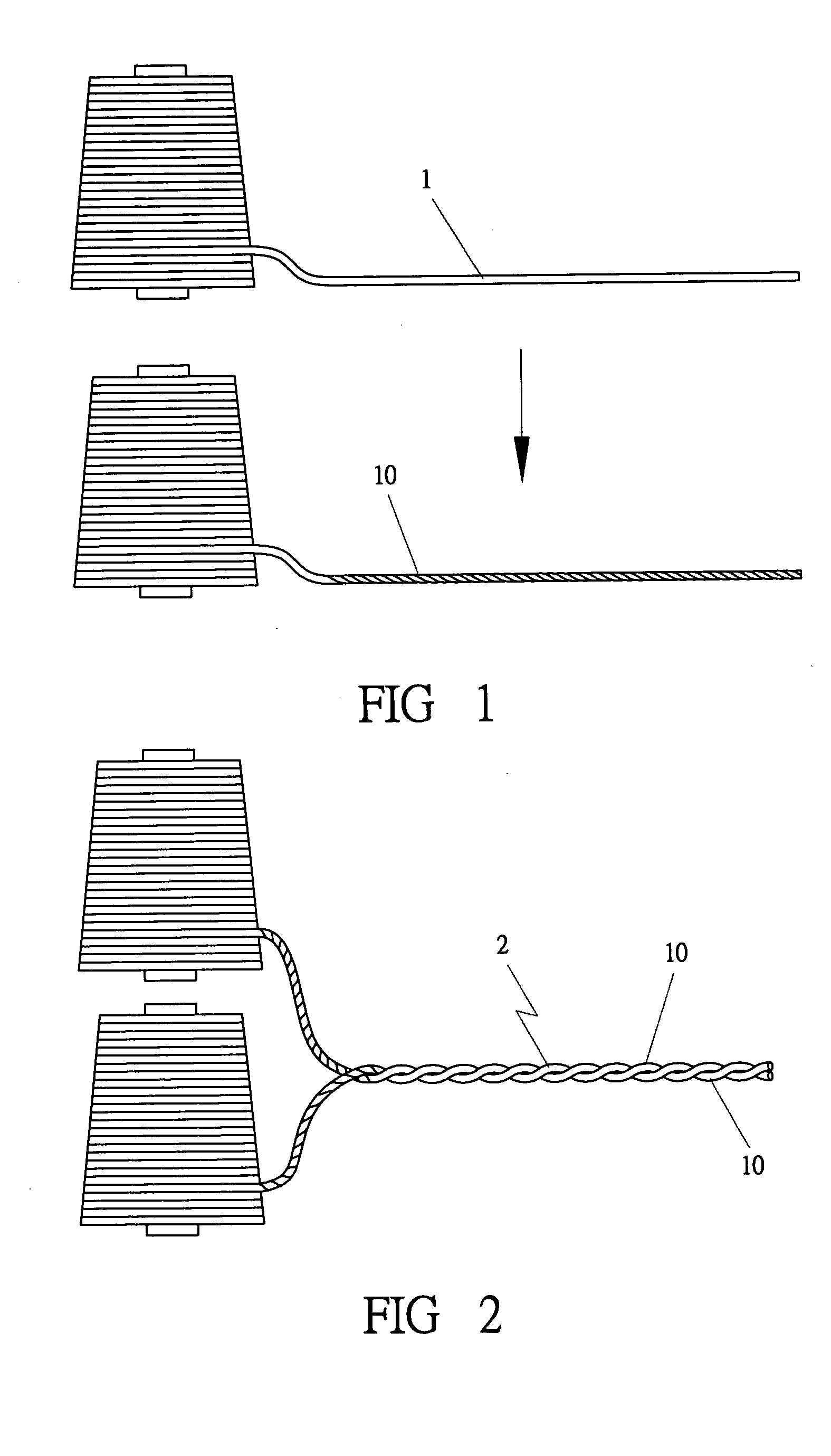

[0023] The first embodiment of the manufacturing method of the furniture fabric in the present invention, as shown in FIG. 1, includes the first step of twisting a single-ply yarn 1 of acrylic, polypropylene, polyethylene, polyester, or polyvinylchloride by a single twisting machine into single-ply yarn 10, which can be the right direction, or the left.

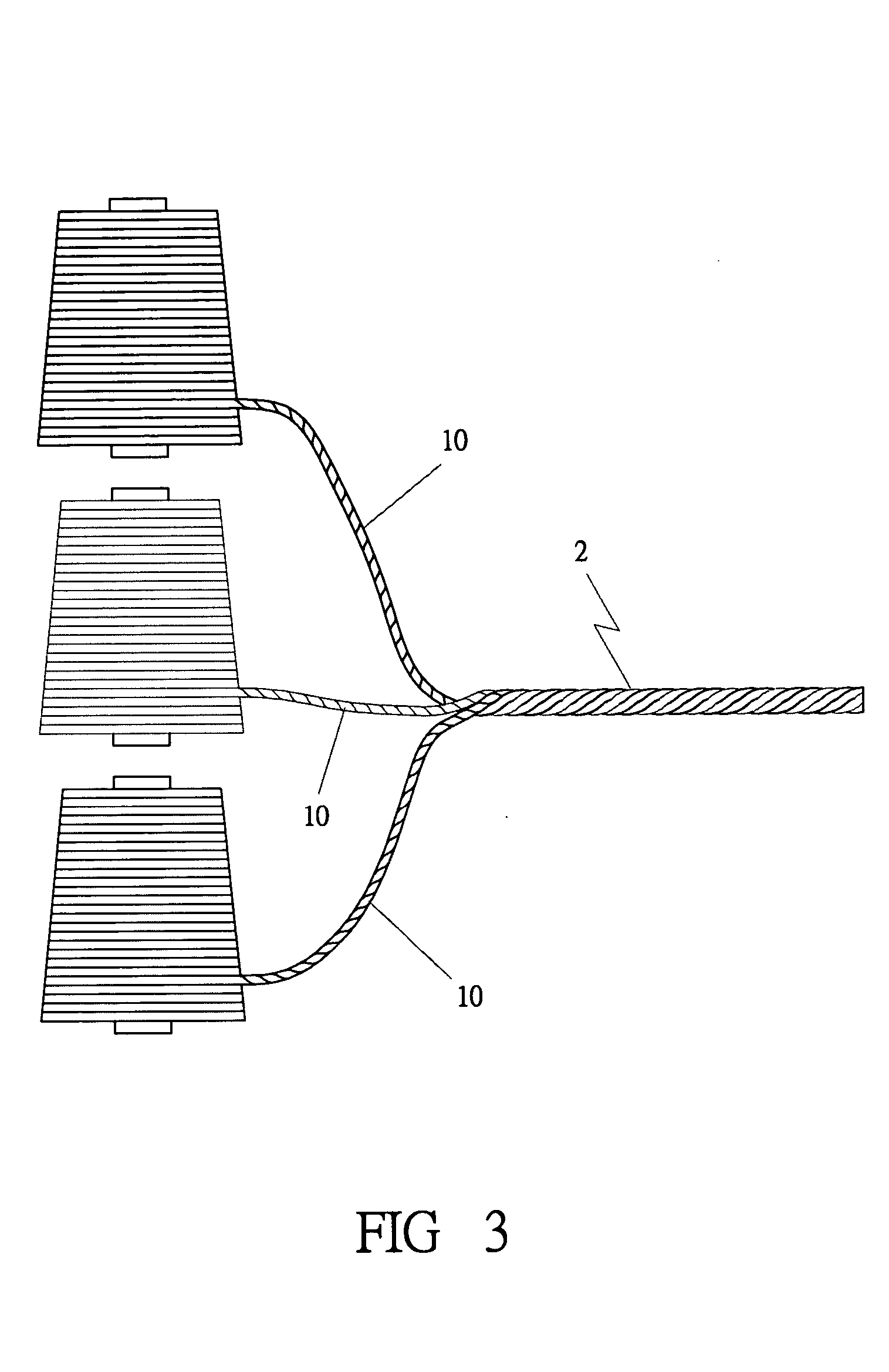

[0024] The second step, as shown in FIG. 2, is to twist two, three, four or more than four single-ply yarns 10 of the same material or different materials (shown in FIGS. 2, 3 and 4) by a plural twisting machine into two-ply, three-ply, or four-ply two-way-twisted compound yarn 2. Thus two-way-twisted compound yarn 2 is made of plural single-ply yarns 10.

[0025] The two-way-twisted compound yarn 2 made by following the first and the second steps mentioned above have the following advantages. When the two-way-twisted compound yarn 2, which as the second step stated, is made of a plurality of single-ply twisted by yarns 10 processed fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tension strength | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

| softness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com