Solar heat absorber panels

a technology of solar energy and absorber panels, which is applied in the direction of solar heat collectors with working fluids, solar heat collectors for particular environments, solar heat collectors, etc., can solve the problems of difficult to fit in the form of an array, and achieve the effect of reducing heat loss, facilitating connections, and being easy to achiev

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The invention will now be described, by way of example only, with reference to the accompanying drawings.

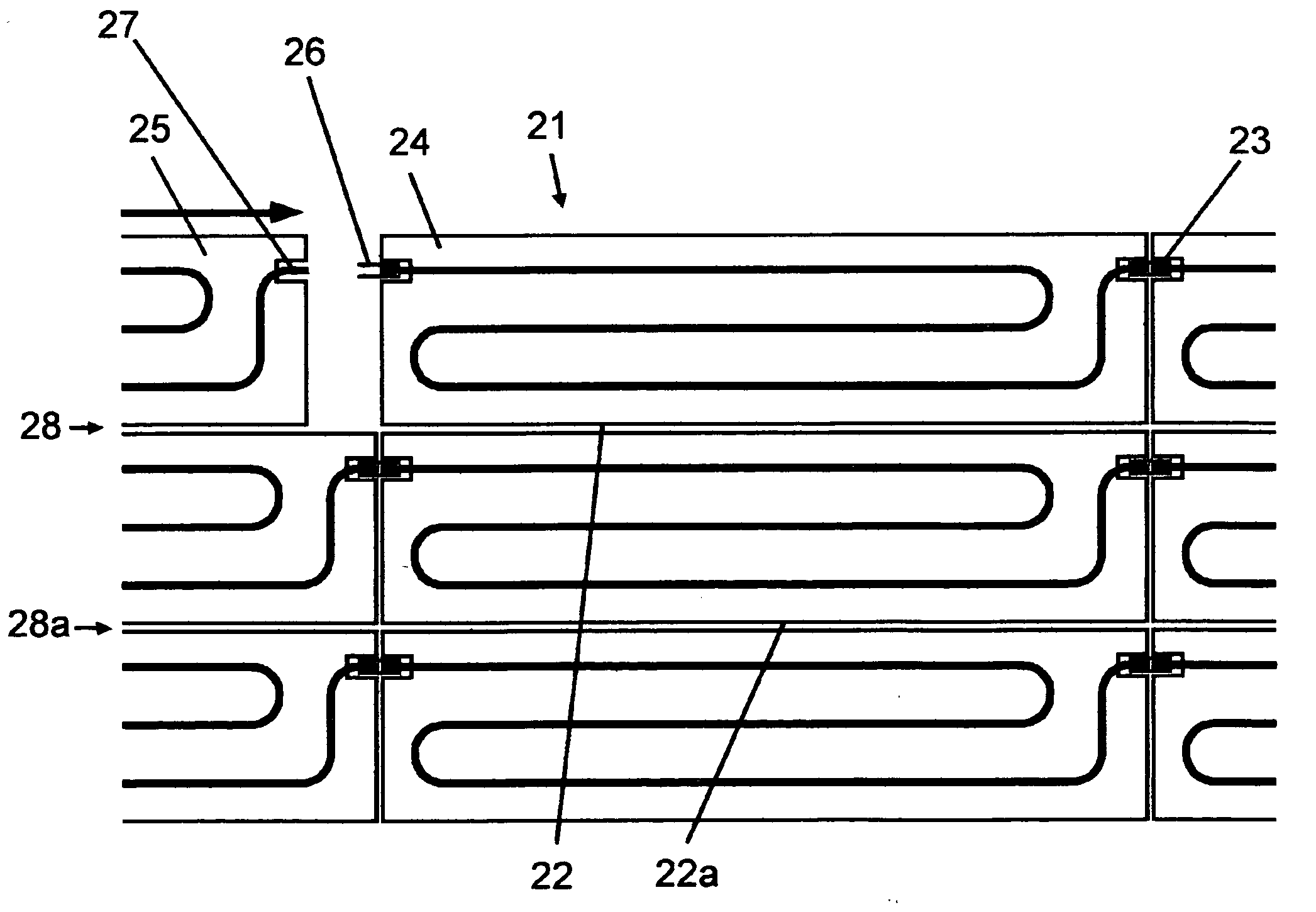

[0016] Referring first to FIG. 1, an absorber panel 11 is made of an aluminium sheet 12 coated in a coating absorptive to solar radiation, to which is welded a copper pipe 13. The pipe 13 traverses the sheet in a serpentine manner, and both ends are terminated at the edge as terminals 15 and 15a. The panel is cut away 16, 16a to allow space for connectors (not shown). An insulation board 14 is attached to the rear of the panel and protrudes at one end so that it underlies the gap between this panel and a second panel placed adjacent to it, so as to provide a barrier to light passing through the gap between the panels.

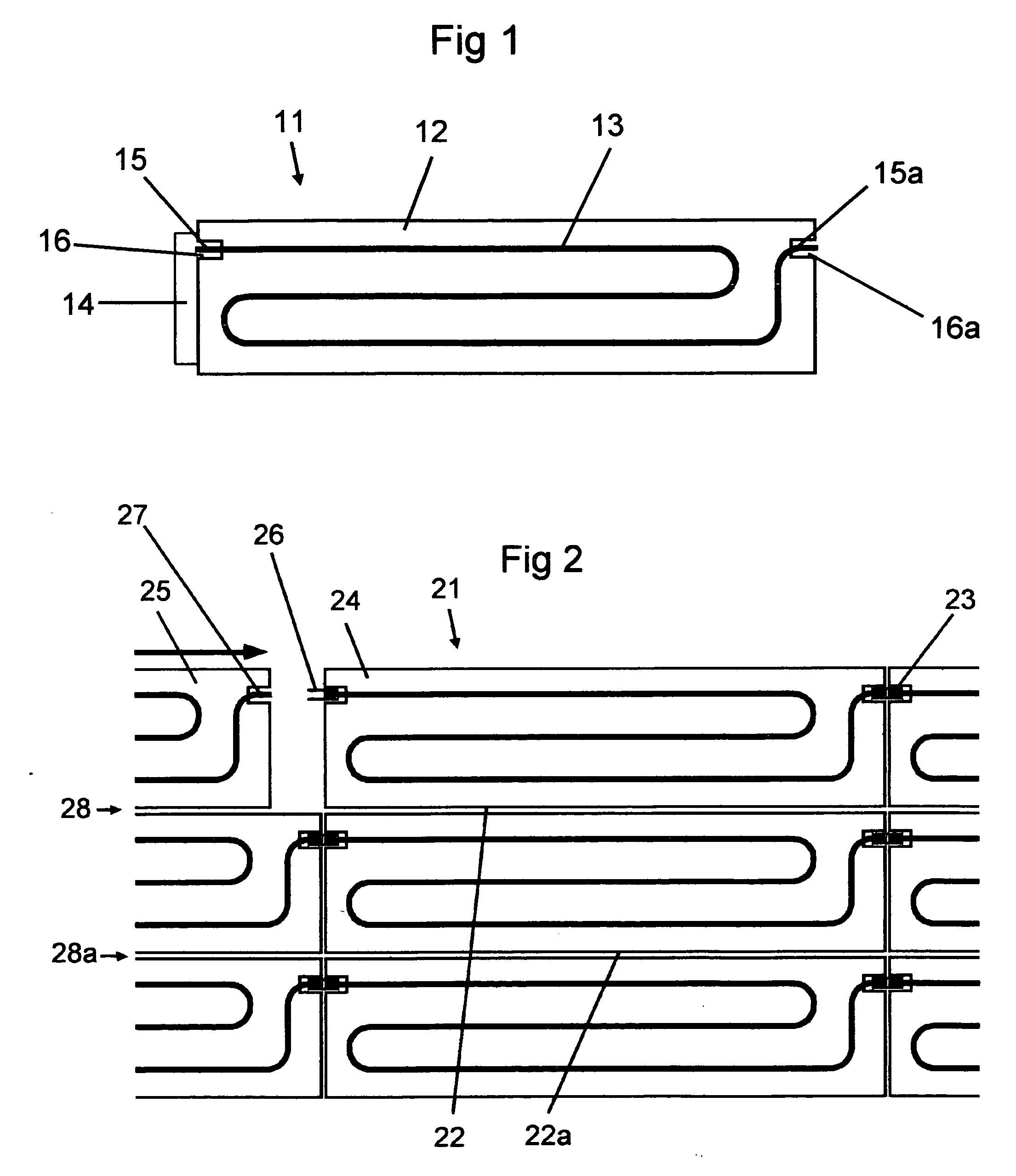

[0017]FIG. 2 shows an array of panels 21 formed of a number of horizontal rows of panels (three rows are shown). The panels are supported by horizontal battens (not shown) along the lines of the panel edges 28, 28a. Note the gaps 22, 22a between the panels w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com