Method and apparatus for laser inscription of an image on a surface

a technology of laser inscription and surface, applied in metal working apparatus, manufacturing tools, welding/soldering/cutting articles, etc., can solve the problems of substantial maintenance problems, high cost of robotic equipment, slow manual operation, etc., and achieve the effect of shortening the light path and less maintenan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

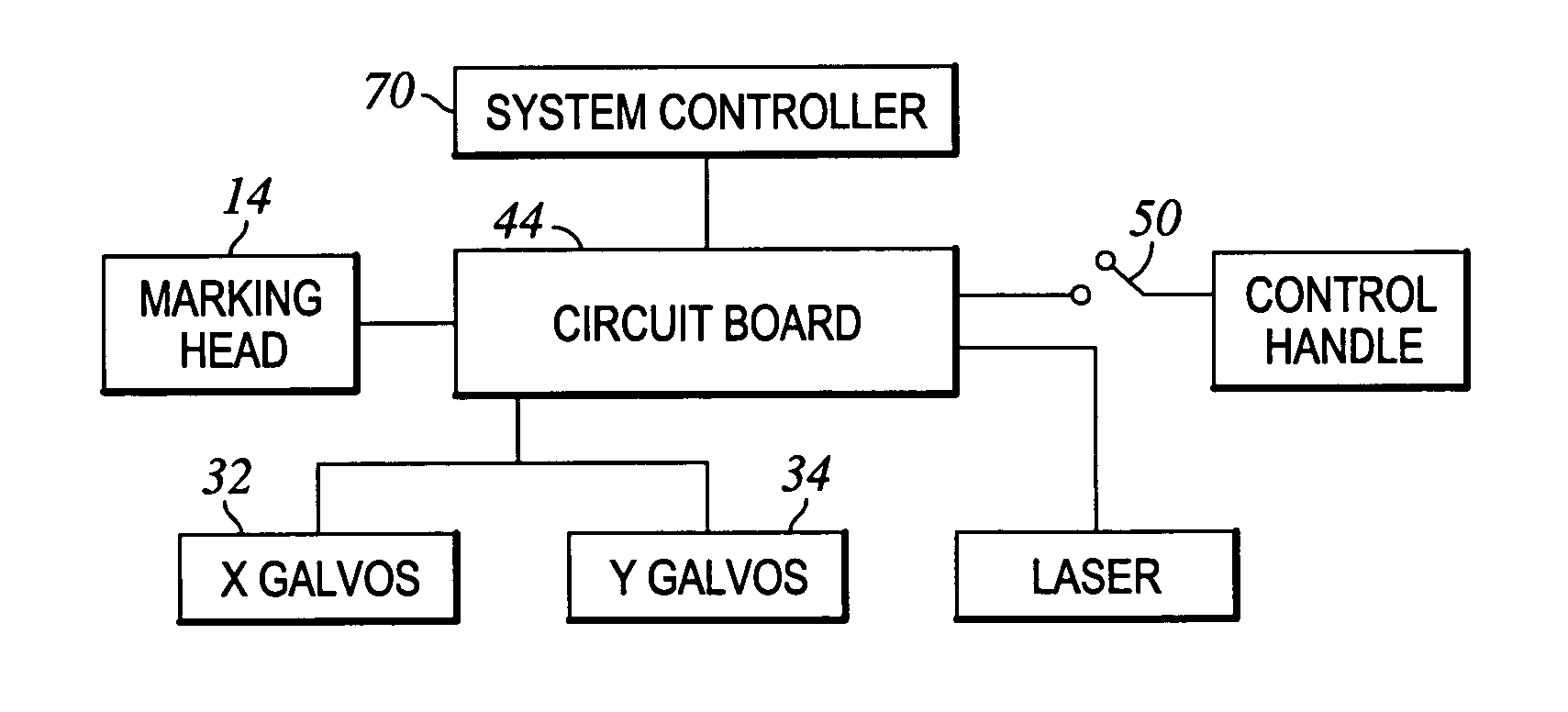

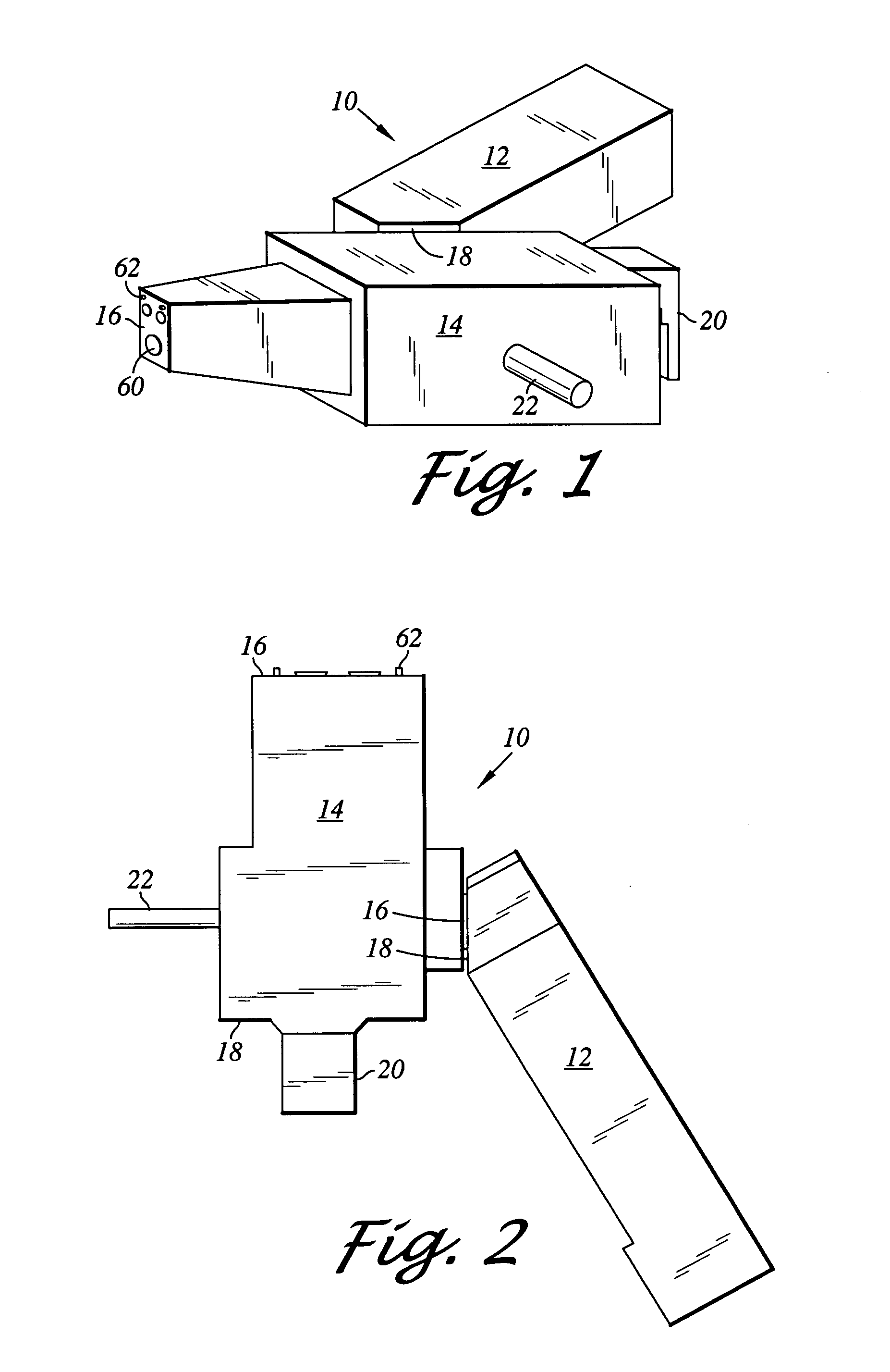

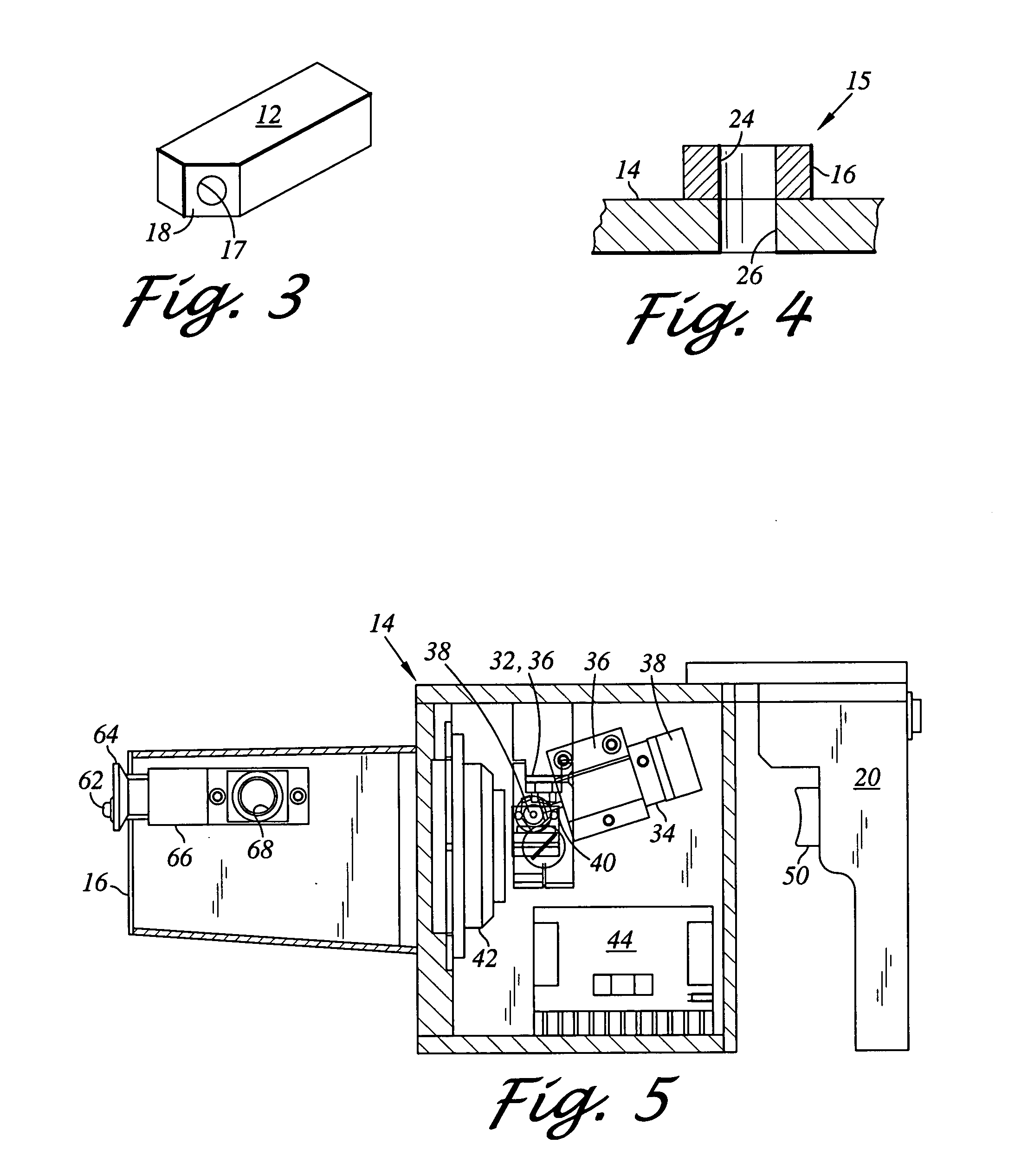

[0028] The invention is described herein in connection with the inscription of indicia on vehicle windows. The apparatus of the present invention, shown generally as 10, is illustrated in a simplified perspective view in FIG. 1 and in top plan view in FIG. 2. The apparatus 10 comprises an emitter housing 12 comprising a housing having top, bottom side and end walls. As illustrated, a marking head 14 is pivotally mounted on a side wall of the emitter housing. A laser source of conventional design that is capable of emitting a beam to which the surface being etched is not transparent and the associated electronics in support thereof are disposed in the emitter housing 12. The laser and associated electronics are connected to a suitable power source (not shown). An eximer or CO2 laser is preferred for use in the present invention because the emission of these lasers is particularly suited for etching oxide containing surfaces such as glass, anodized aluminum, ceramic oxides and the lik...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission power | aaaaa | aaaaa |

| emission power | aaaaa | aaaaa |

| energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com