Tank closure

a technology for tanks and tanks, applied in the field of tanks, can solve the problems of substantially more difficult to screw the tanks in or out, and achieve the effect of reducing the risk of sparking and achieving the greatest possible potential equalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

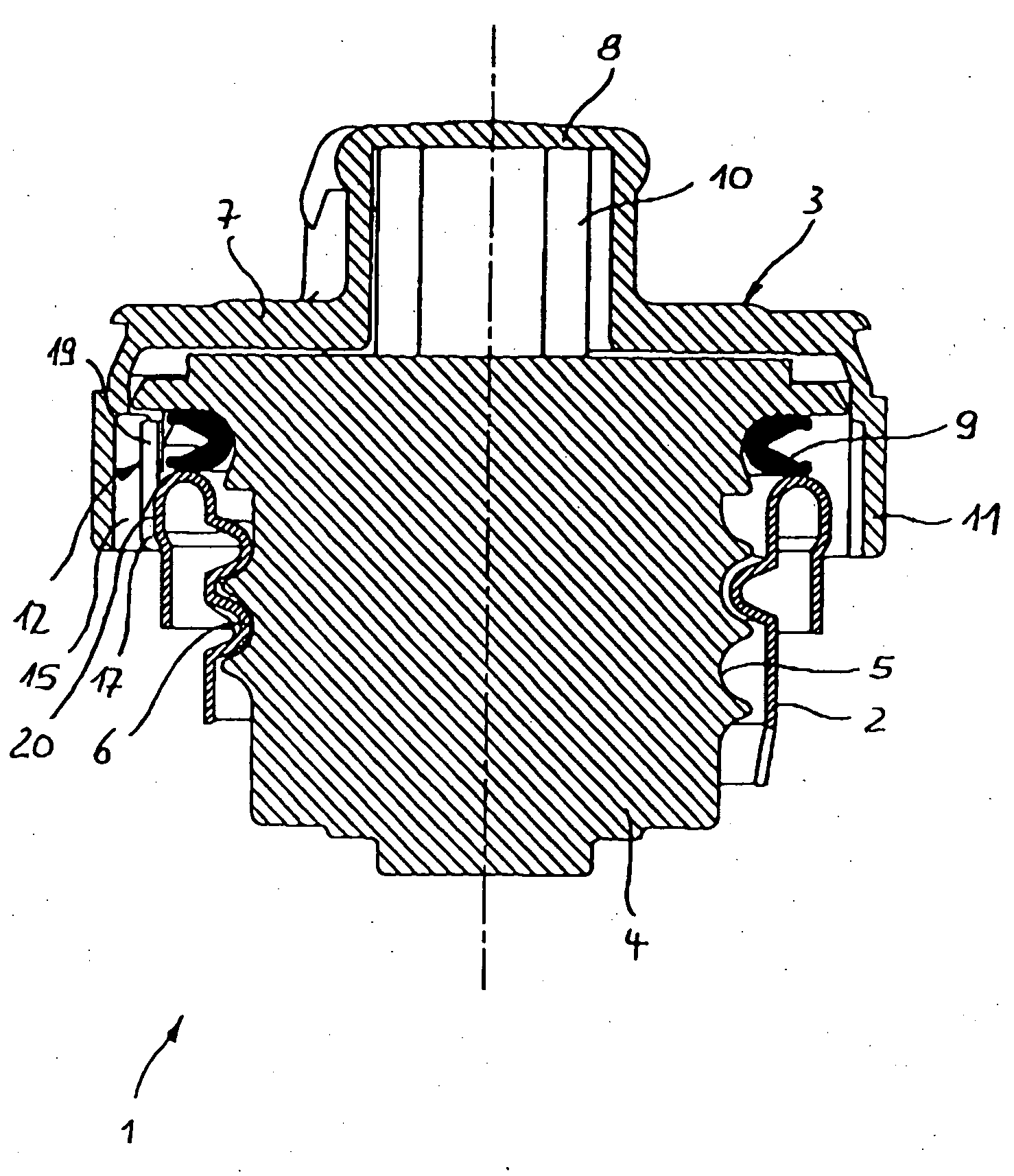

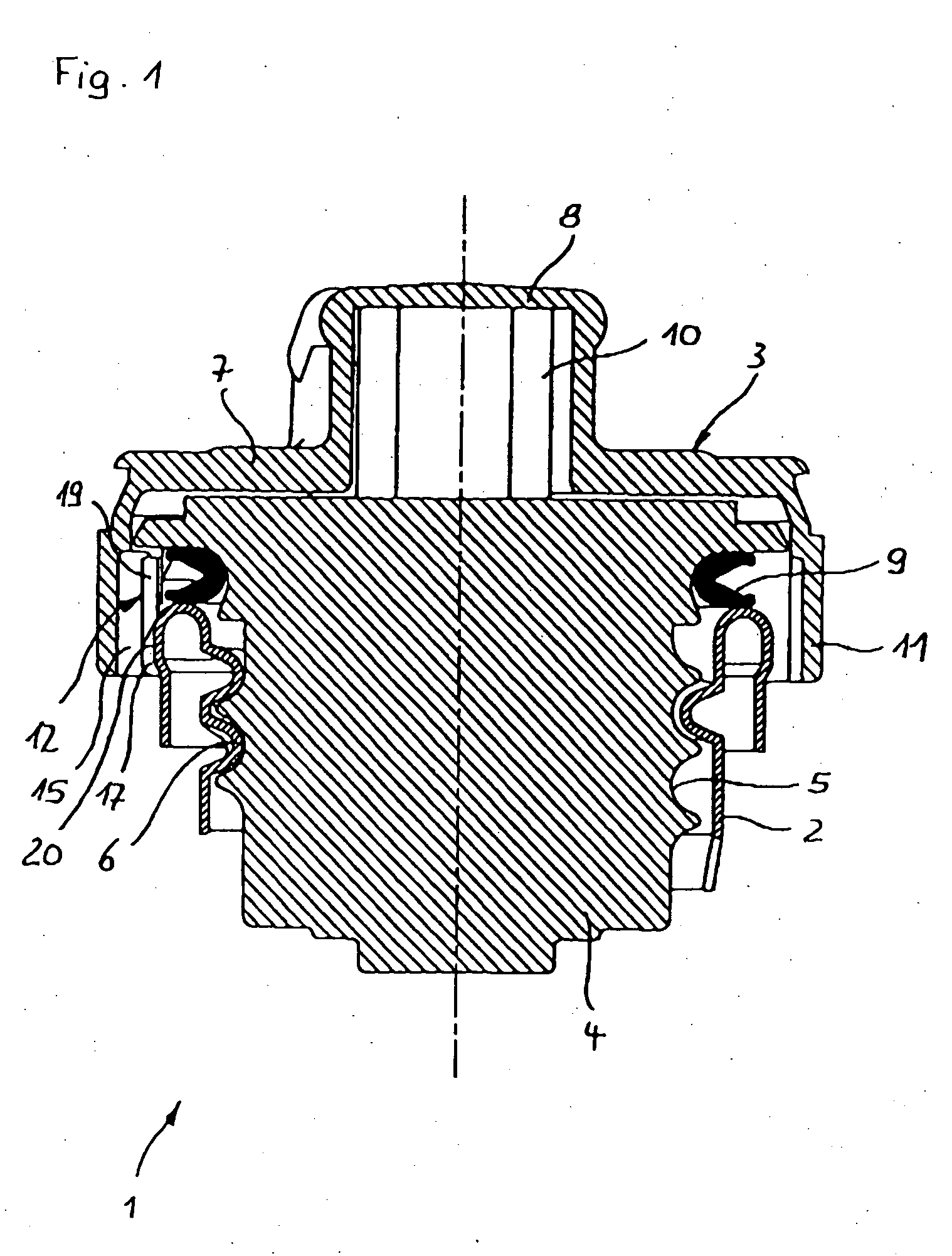

[0017] Tank closure 1 depicted in FIG. 1 comprises the upper end of a tank neck 2 made of metal, and a tank cap 3 screwed thereinto. The tank cap has an engagement part 4 that externally comprises a thread 5 that fits into a corresponding thread 6 on the inner side of tank neck 2. A hat-shaped grip portion 7 having an elevated grip flange 8 is slipped over engagement part 4. In the upper region, engagement part 4 is surrounded by a sealing ring 9 that rests sealingly on the end face of tank neck 2. The parts contained in engagement part 4, such as the positive and negative pressure valves, etc., are not explicitly depicted because they are not part of the subject matter of the present invention.

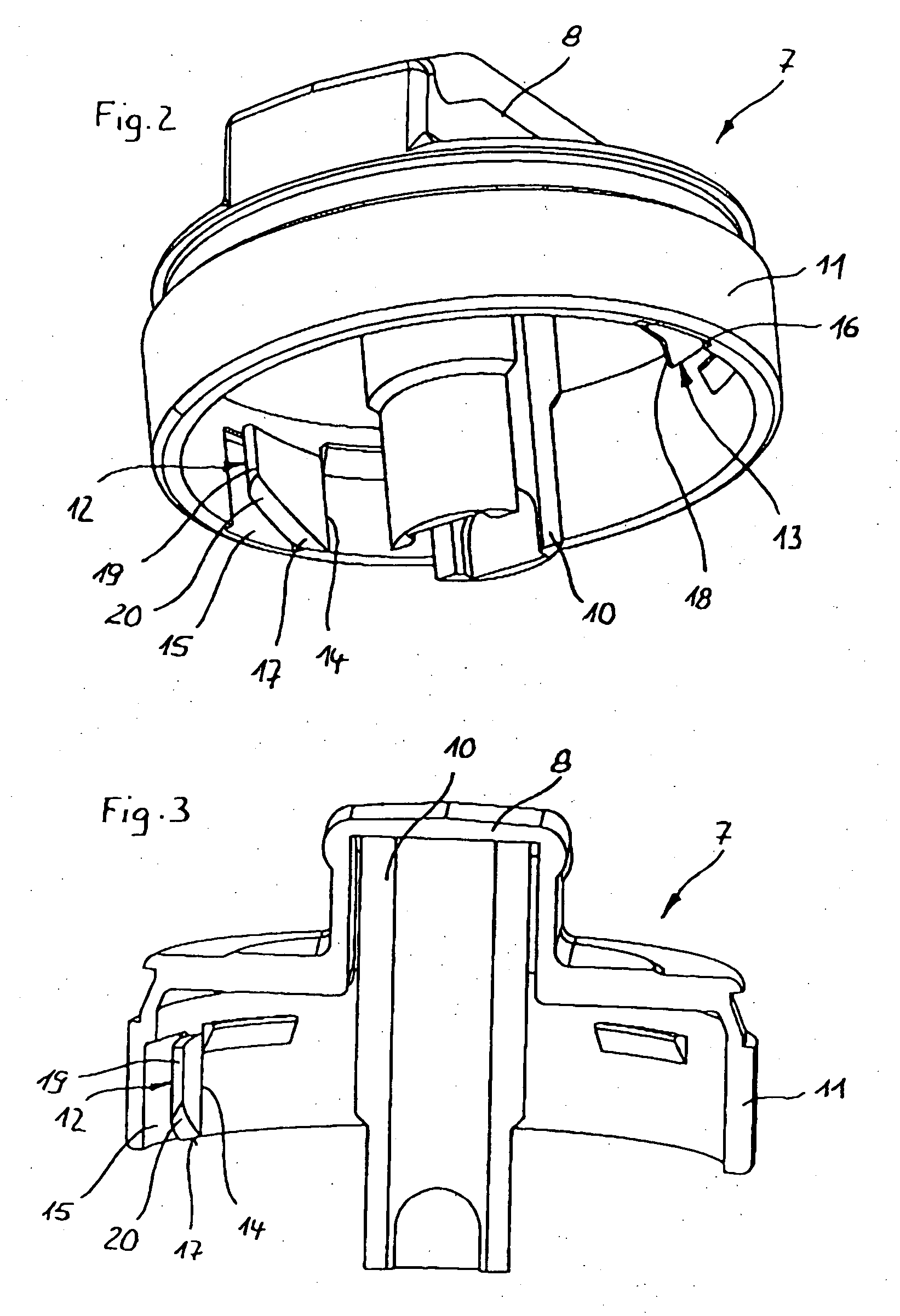

[0018]FIGS. 2 and 3 show only grip portion 7, of tank cap 3, a coupling cylinder 10 being present that which extends centeredly into grip flange 8 and ensures a nonrotatable connection between grip portion 7 and engagement part 4. Grip portion 7 is made of an electrically conductive plastic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com