Container capping control device and method and associated machine

a control device and container capping technology, applied in the direction of caps, closures using caps, applications, etc., can solve the problems of long stoppage time, high cost of stopping production, and the device is complicated without ensuring highly reliable and convenient closures, etc., to achieve convenient parameterization and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

A machine for applying caps onto bottles may be installed in a bottle processing line. The bottles generally follow a circular arc trajectory in the machine. The bottles receive a cap that is screwed on or snap-fastened. The bottles afterwards exit the machine. The caps are taken up one by one by holding members which move toward the neck of a bottle, for example by virtue of a vertical downward movement. Each cap is each attached to a bottle by rotation or by snap-fastening. The caps are applied to the bottles when the bottles are following along the circular arc trajectory in the machine.

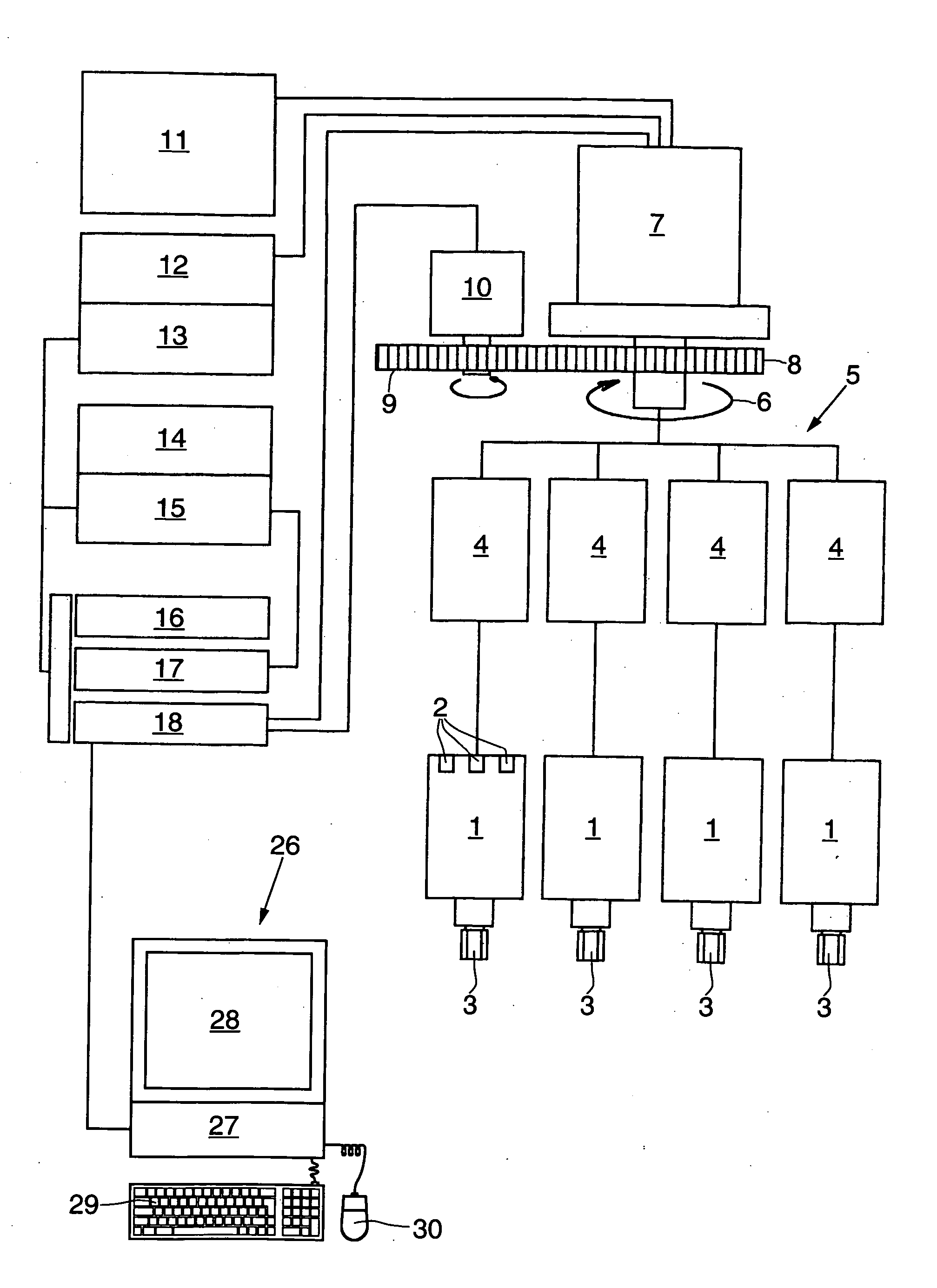

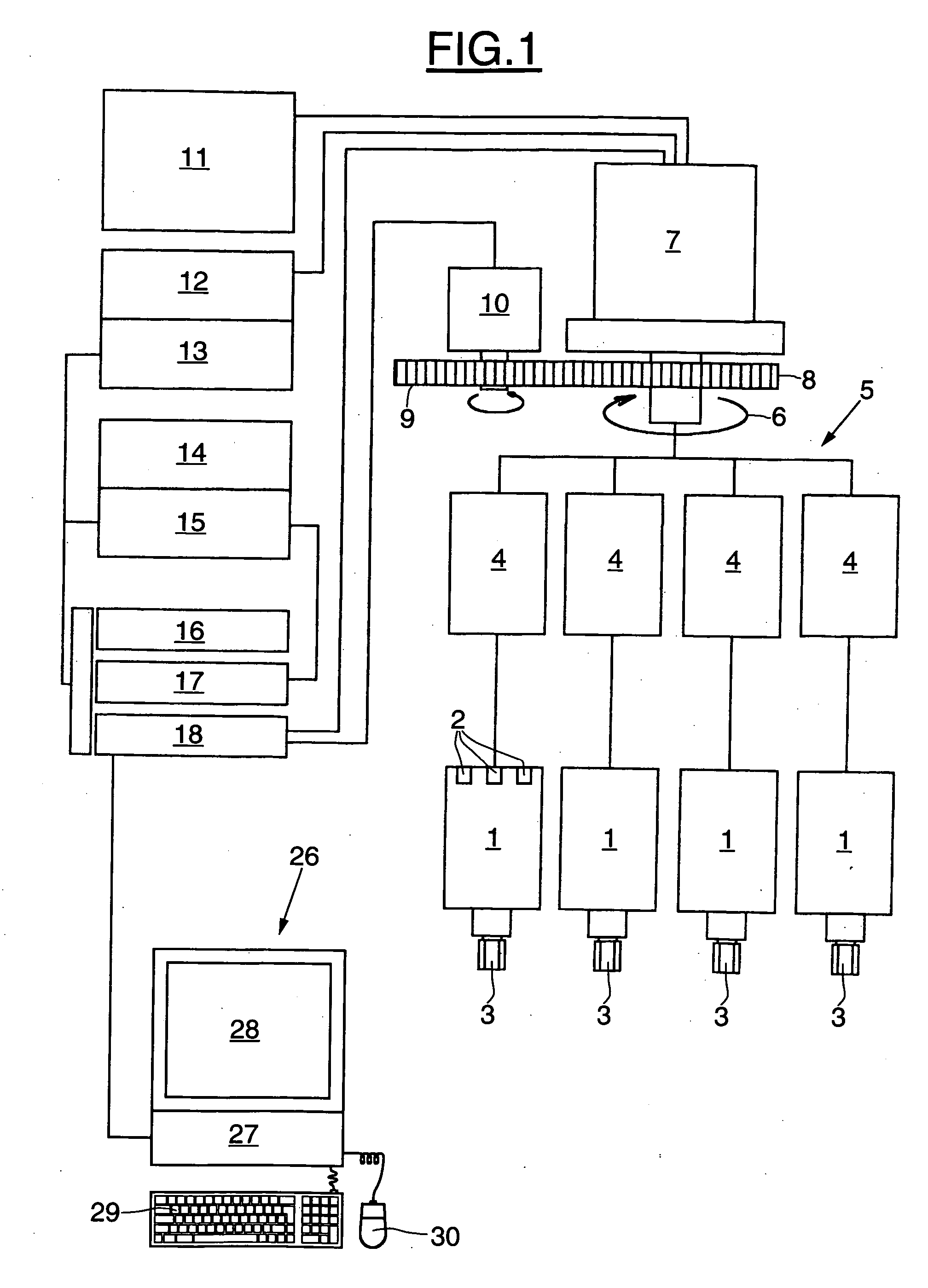

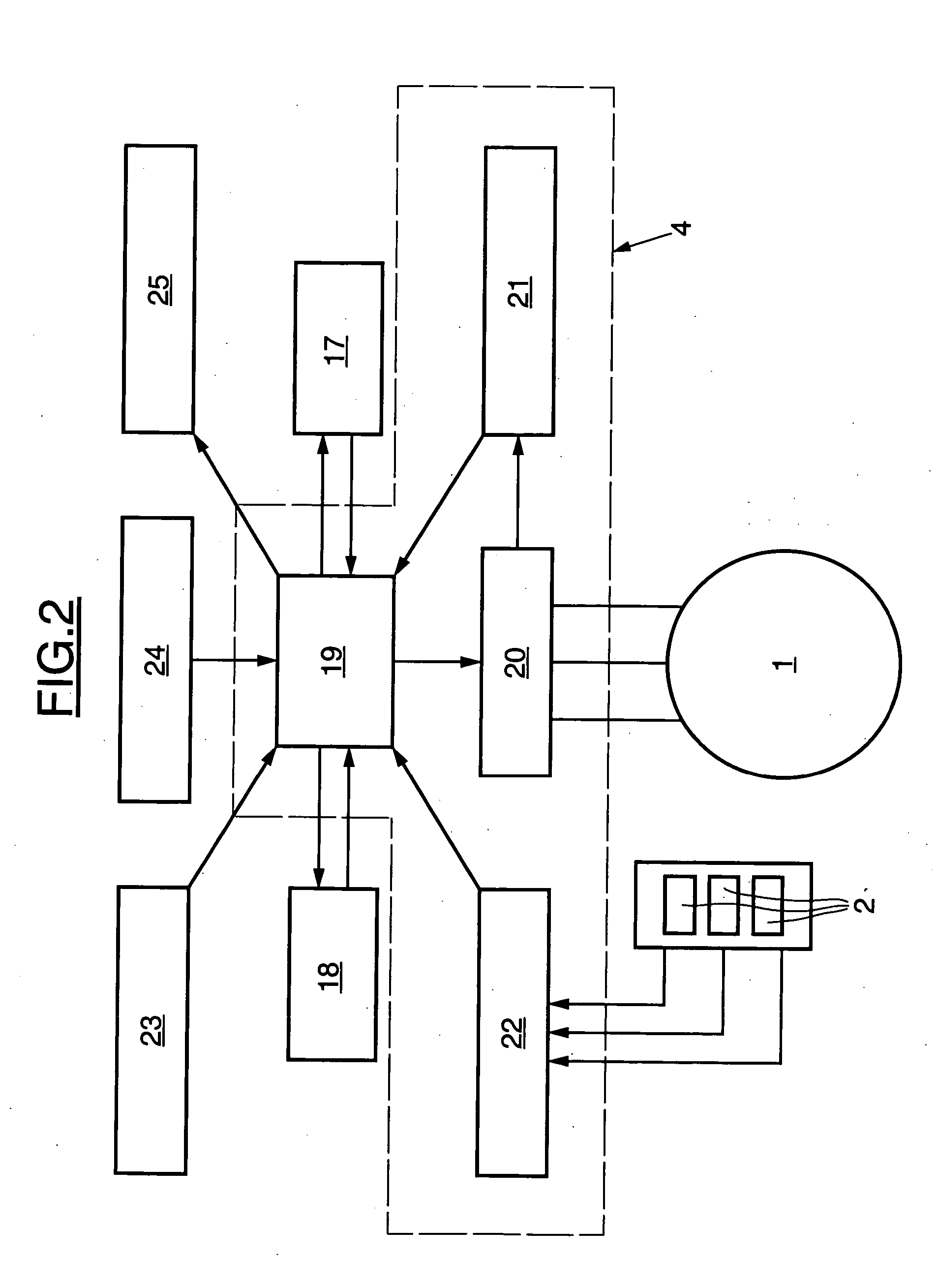

Diagrammatically, the cap screwing machine includes a plurality of motors 1 each associated with a controller 4 adapted to provide the motor with an appropriate electrical power supply. The holding members that are normally fitted to the output shaft of the motors are not shown. The motors 1 and the controllers 4 form part of a rotary assembly, usually called a turret 5. The turret may be adapted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com