Apparatus and methods for coverlay removal and adhesive application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

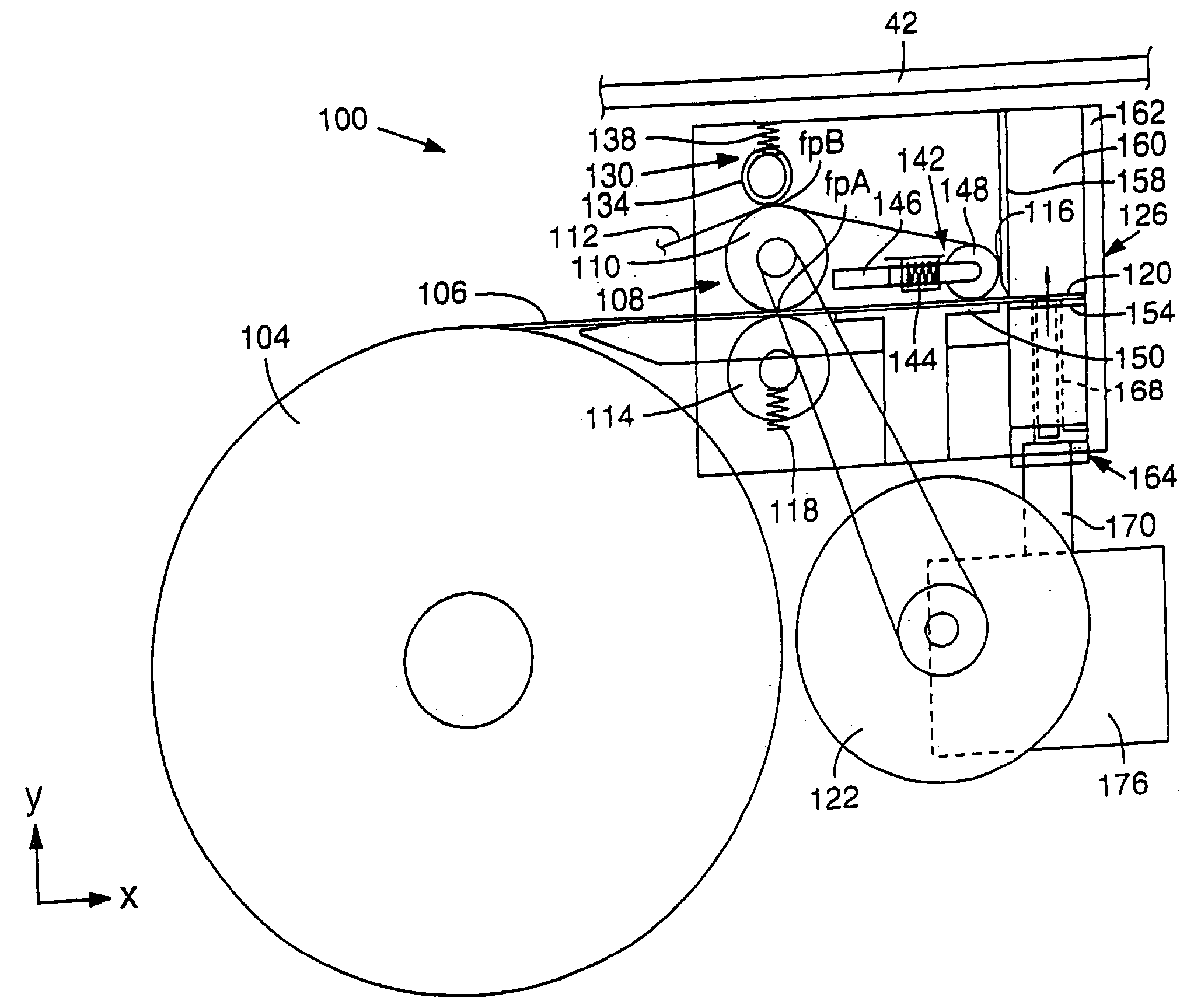

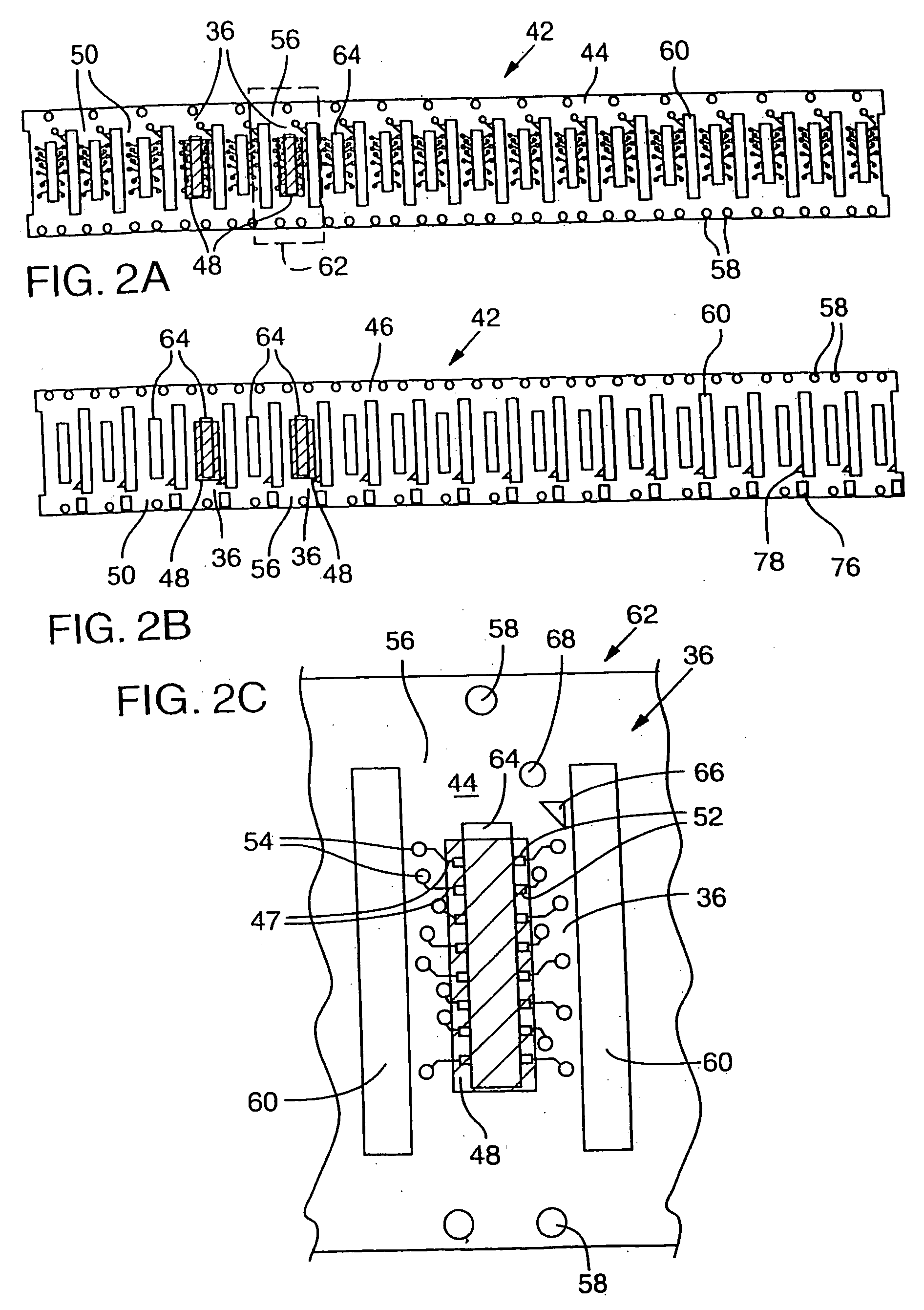

[0019] The present invention provides apparatus and methods for attachment of an adhesive strip as a cover member on one or more reject die sites 36 of semiconductor package support elements 42 (FIG. 2a and 2B). The apparatus and method of the present invention synchronously remove a coverlay film from a reel of adhesive film as it cuts and applies exact lengths of adhesive to the support element.

[0020] With reference to FIGS. 2A-2C, a representative support element 42 includes multiple substrates 56. Each substrate 56 is a segment of the support element 42 and will subsequently be separated from the adjacent substrates 56. The support element shown in FIGS. 2A and. 2B includes 18 substrates 56. However, this number is merely exemplary and the support element 42 may include a fewer or greater number of substrates 56. The substrates 56 are typically positioned side-by-side and are integrally connected. As stated above, the support element 42 facilitates the fabrication process in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com