Backpack having framesheet assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

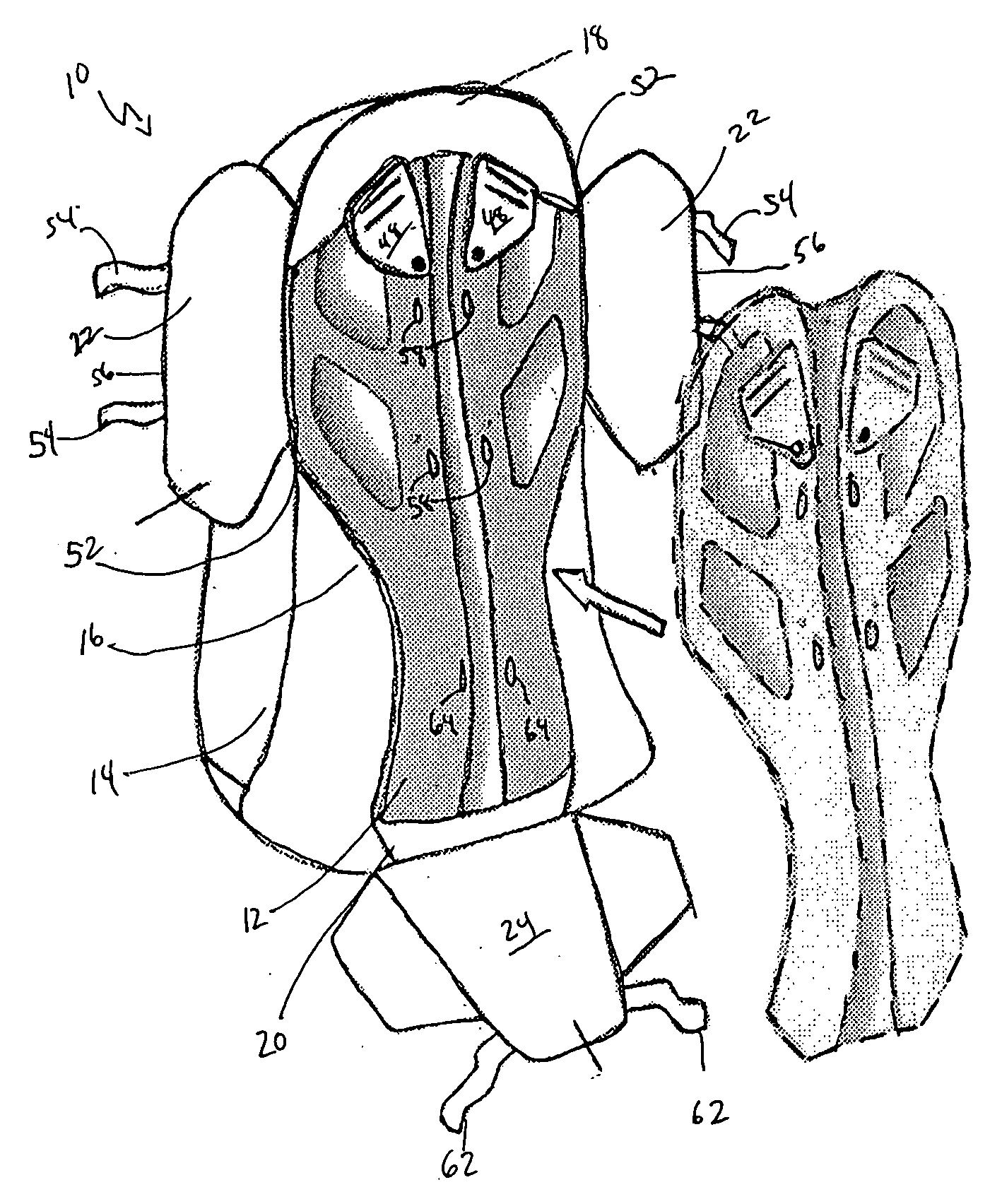

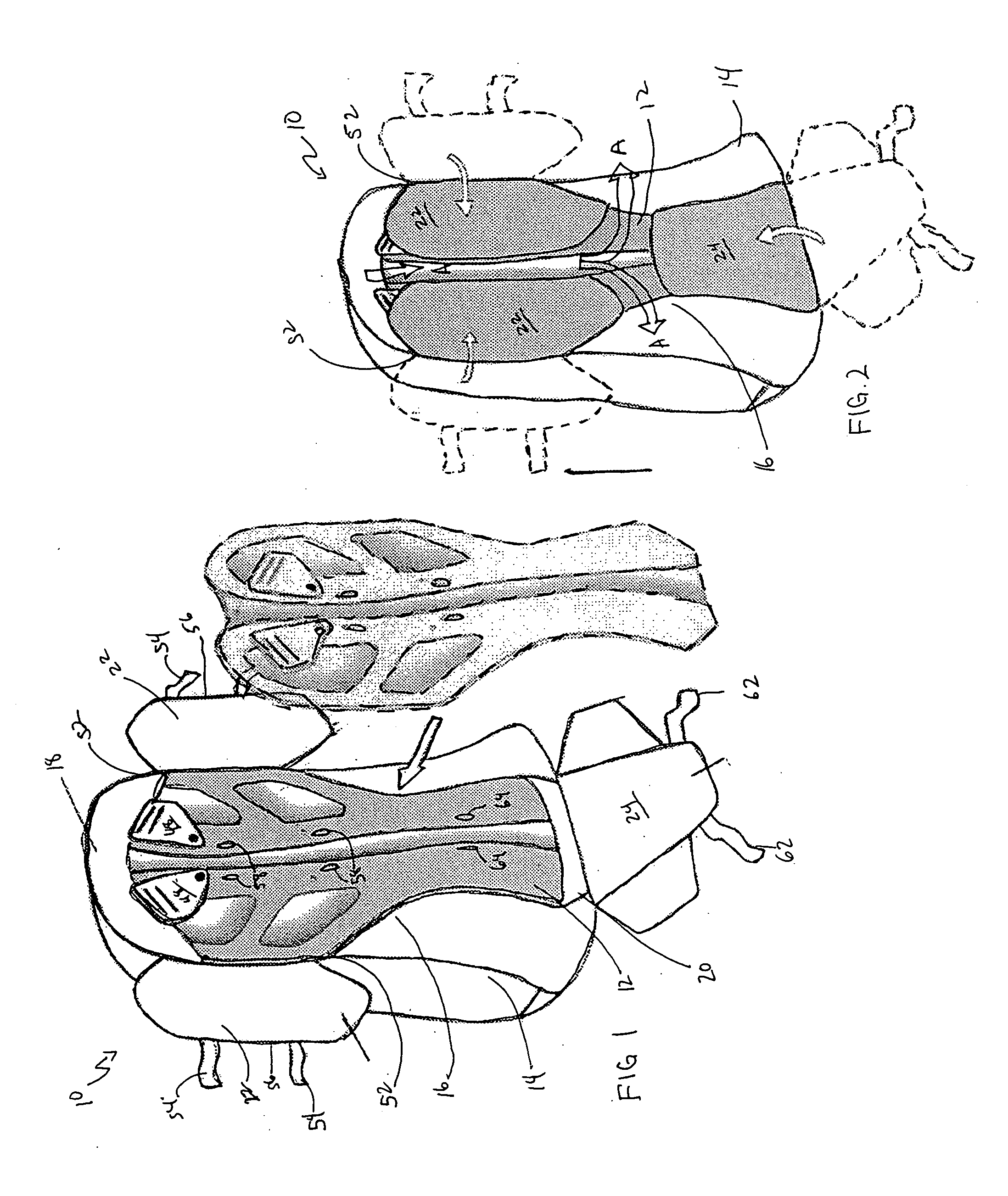

[0023] With reference to the illustrative drawings, and particularly to FIG. 1, there is shown a backpack 10 having a framesheet 12 and a sack 14 for carrying a load. The framesheet is received within a recess defined on a backside 16 of the sack. The sack includes top and bottoms sleeves 18, 20 into which top and bottom edges of the framesheet are received, respectively. The sack further includes scapula pads 22 and a lumbar pad 24 that at least partially cover the framesheet, once fully assembled. When worn, the backpack snuggly conforms to the back of the user and, yet provides ample ventilation, as depicted in FIG. 2 by arrows A. As discussed in detail below, the backpack also provides superior torsional flexibility and load support.

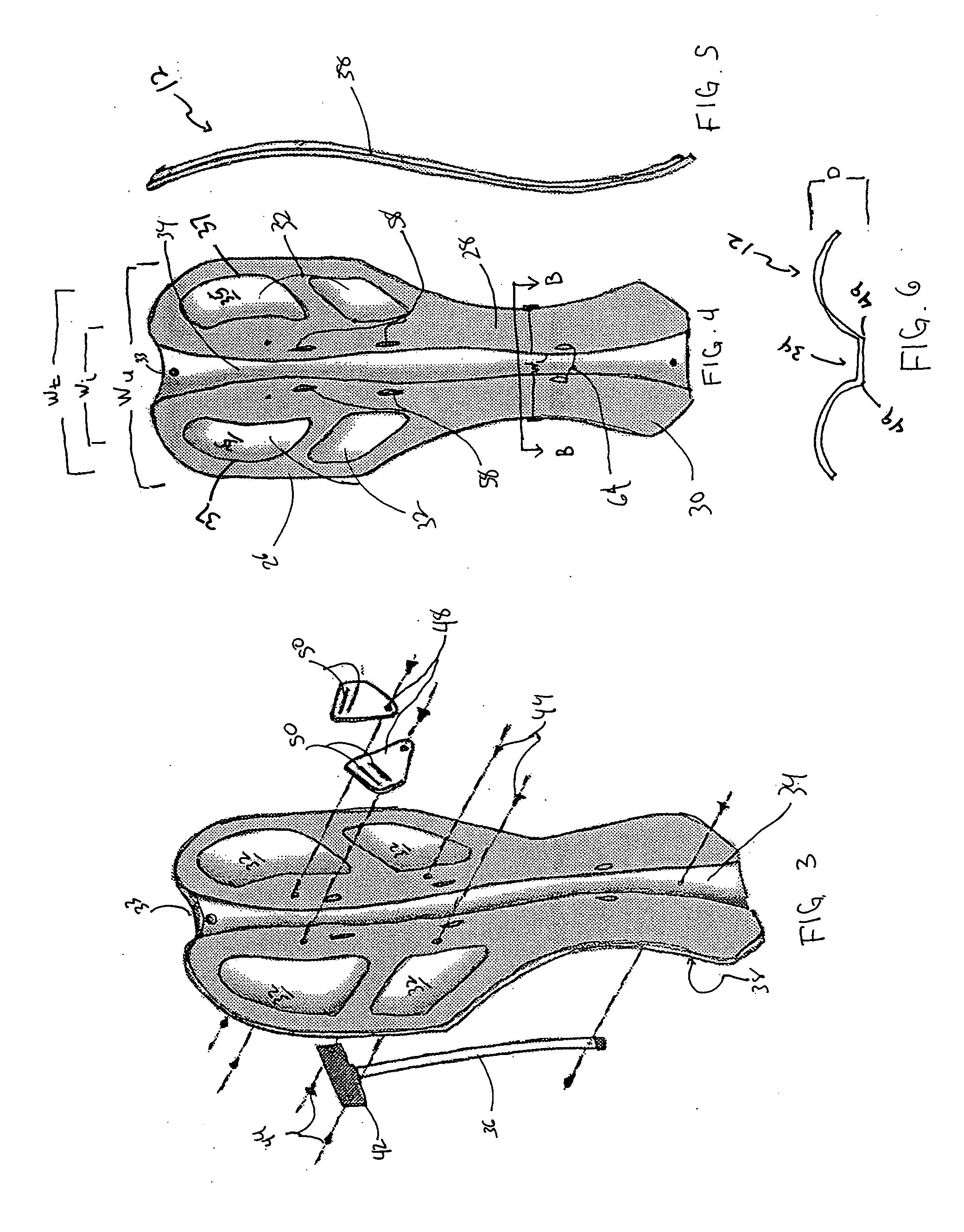

[0024] With reference now to FIGS. 3-5, the framesheet 12 has an upper region 26 generally disposed adjacent to the scapulas of the user, an intermediate region 28, and a tail region 30. In this embodiment, the framesheet generally has an hourglass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com