Method and apparatus for building and transferring a tread belt structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

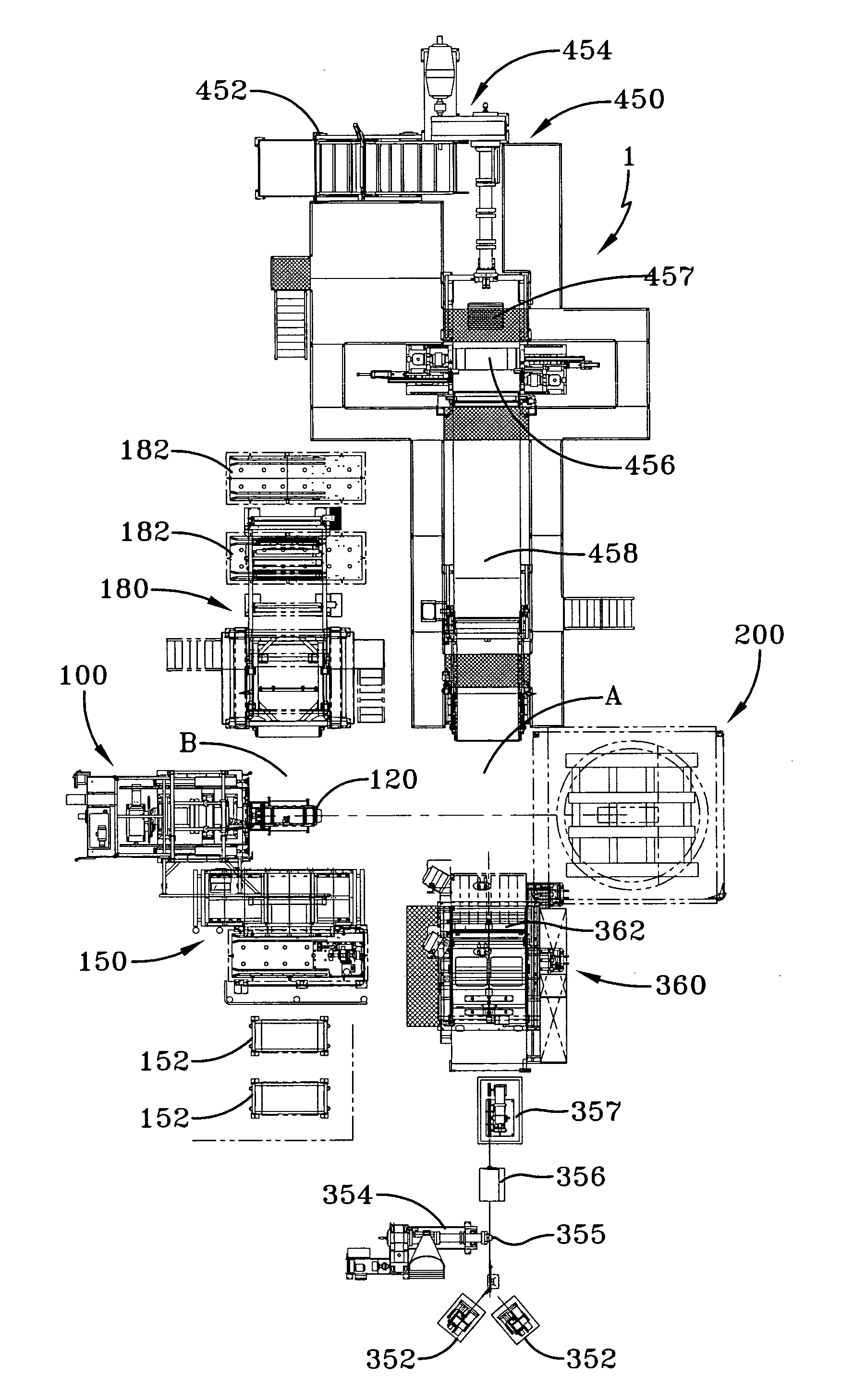

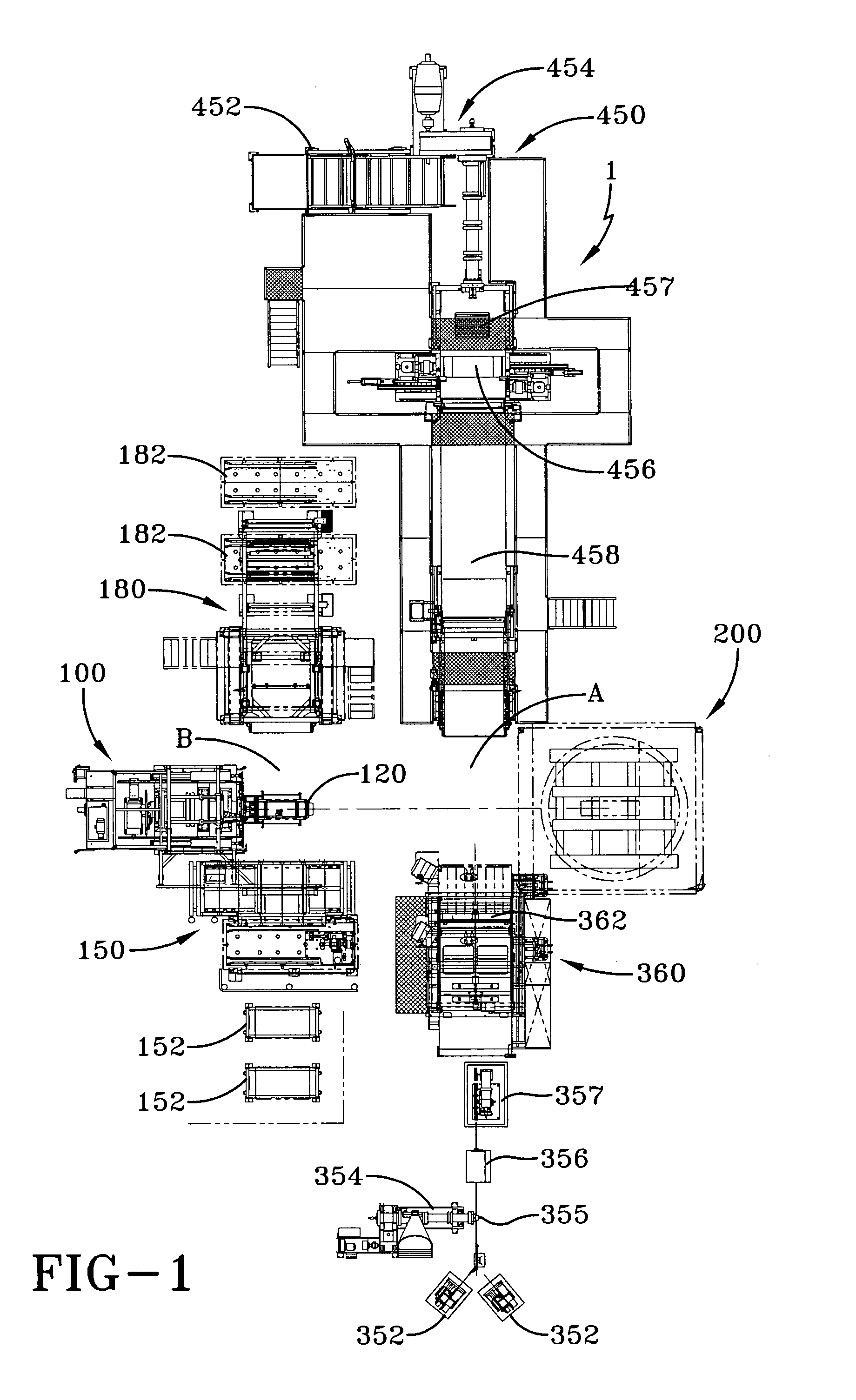

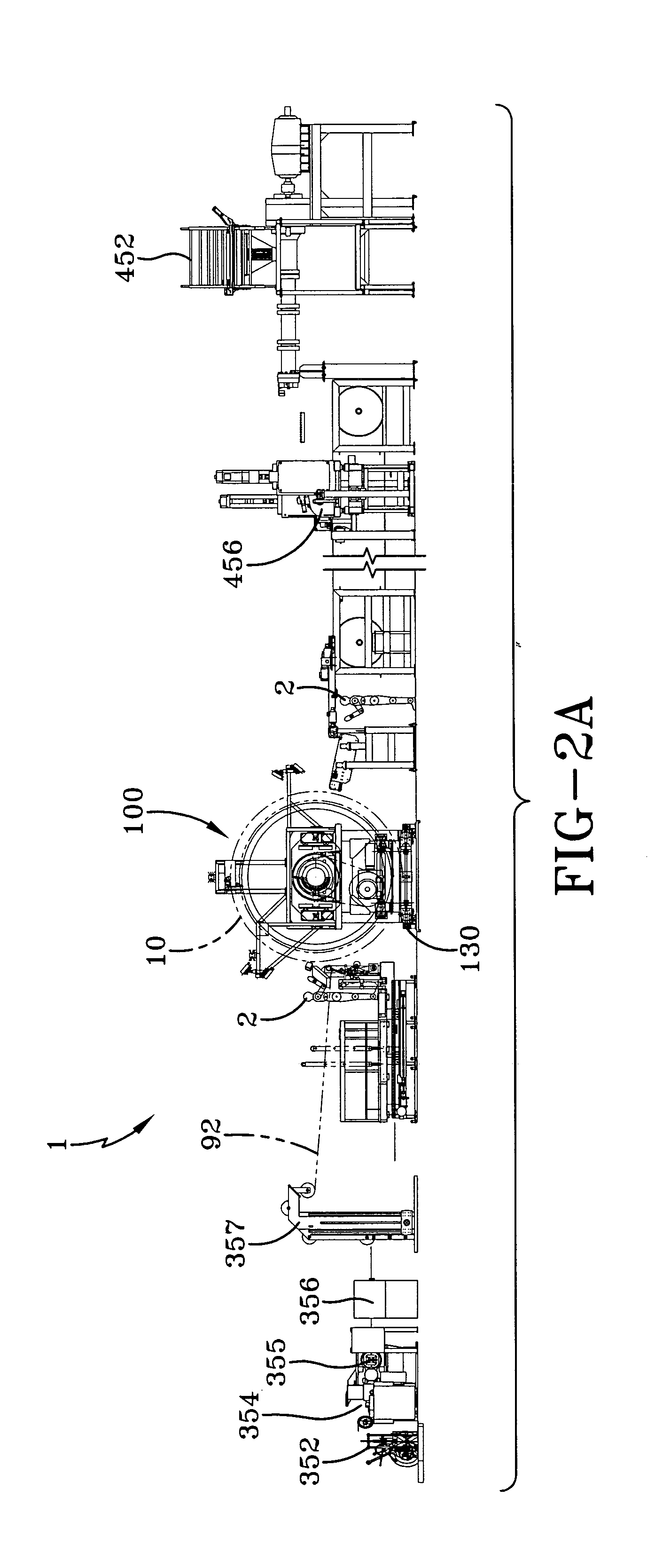

[0058] A method and apparatus for forming a tread belt is disclosed. With reference to FIGS. 1, 2A and 2B, a system for forming a tread belt assembly for a large two piece tire assembly is shown. The system 1 as illustrated in FIG. 2B has a tread building drum 10 attached to a means 100 for building the tread belt assembly and a transfer means 200 for accepting the tread belt assembly 4 and the building drum 10.

[0059]FIG. 2A shows a portion of system 1 from an elevation or side view. The means 100 for building the tread belt 4 is positioned about midway between the various mechanisms for forming the components that make the tread belt assembly 4

[0060] As shown in FIG. 1, an overhead view of the system 1 is illustrated. The means 100 has various mechanisms on each side of the building shaft 120. As shown, the building drum 10 and the rail mechanism 130 which permits the means 100 to move between a first position A and a second position B are not illustrated. As shown in FIG. 1, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Weight | aaaaa | aaaaa |

| Elastomeric | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com