Cooling apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0094] (First Embodiment)

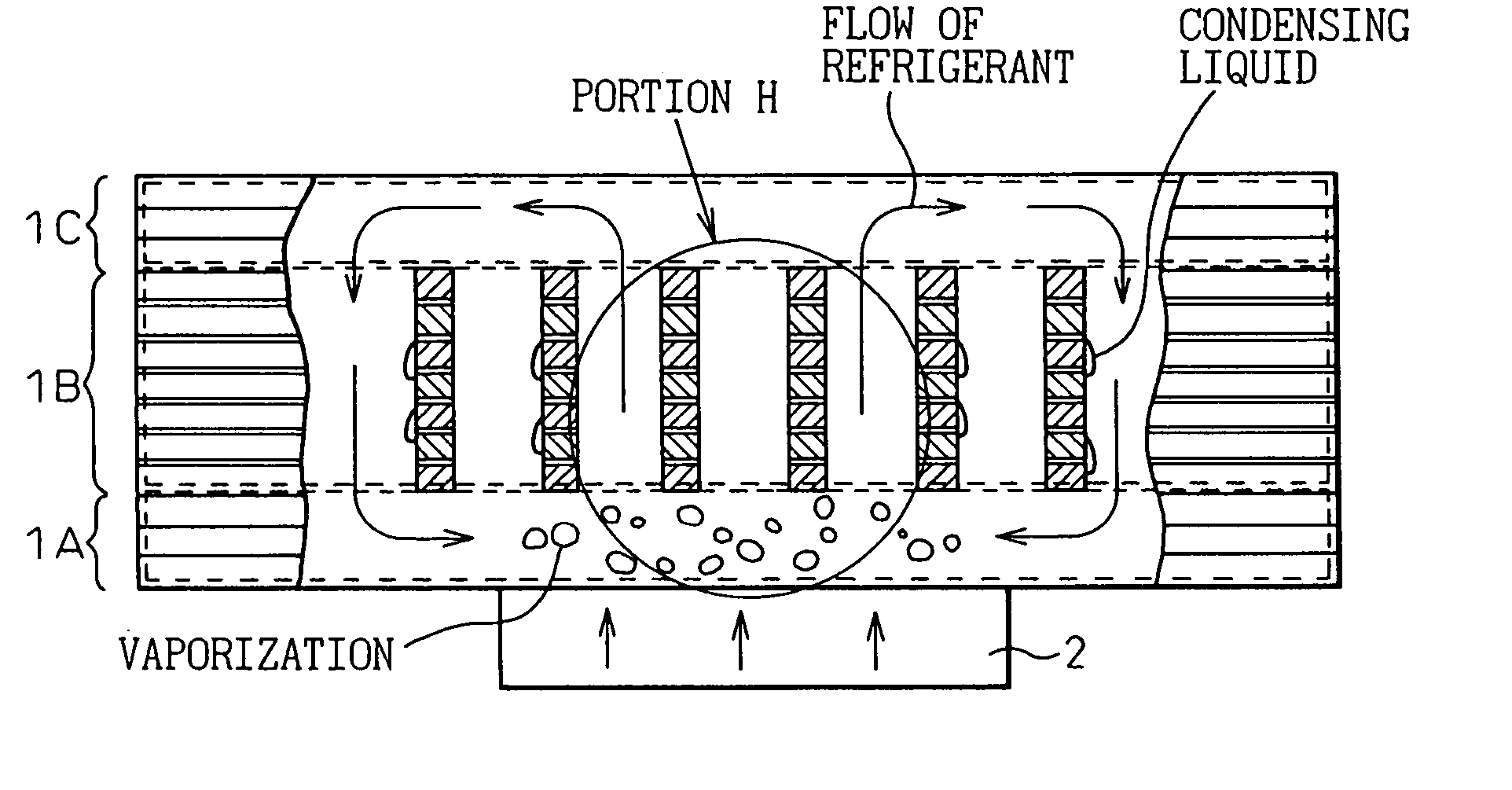

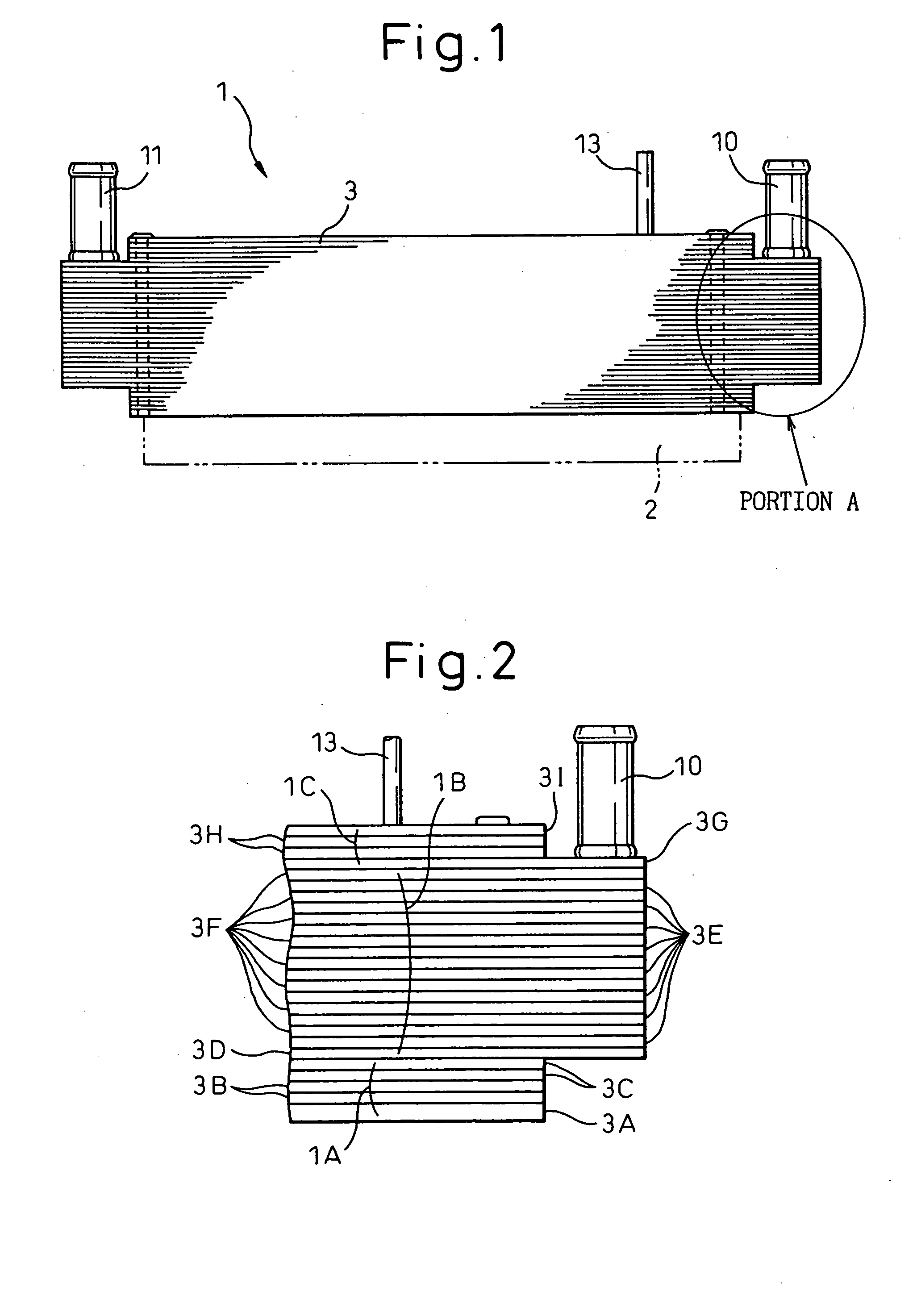

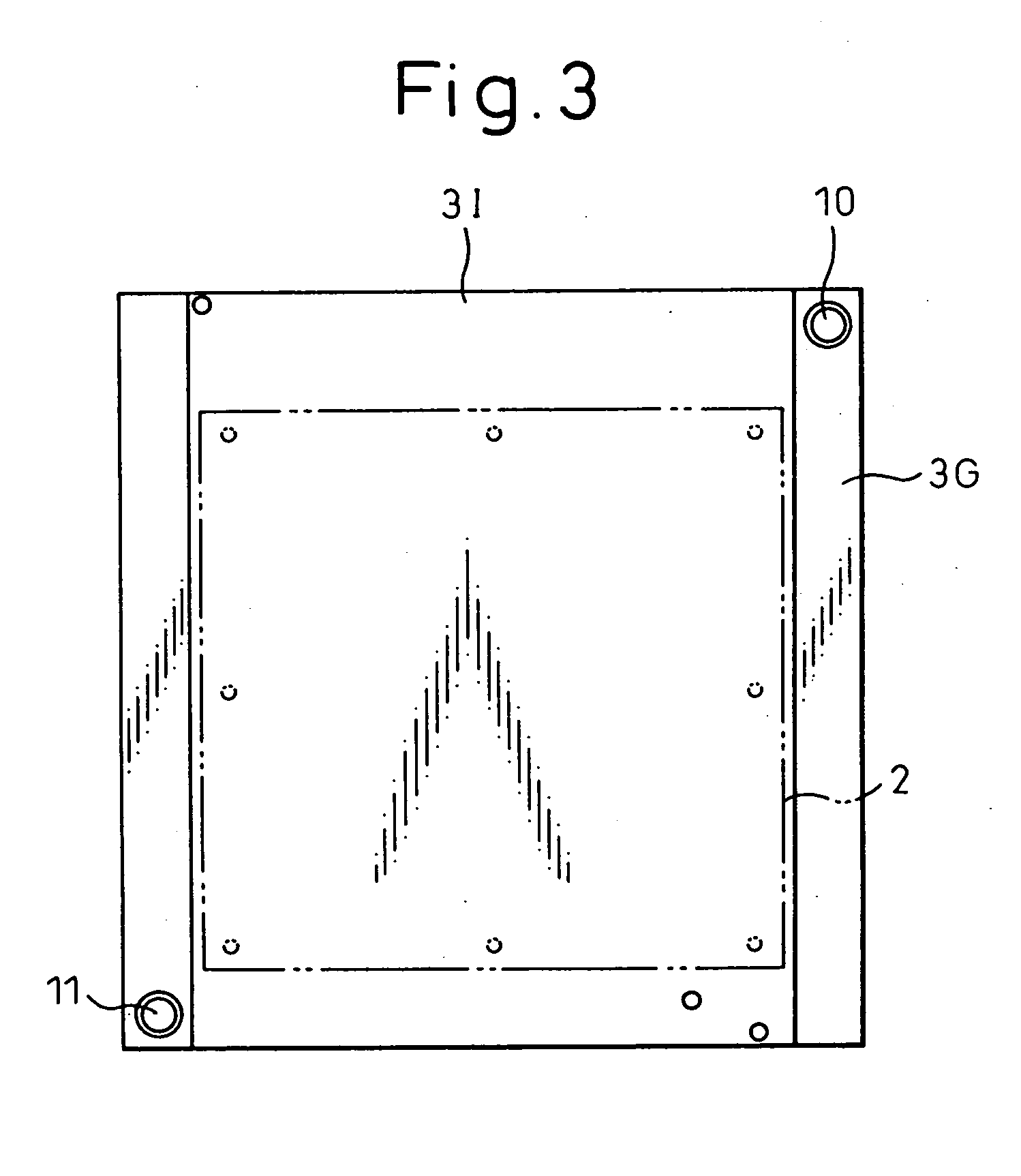

[0095]FIG. 1 is an overall side view of a cooling apparatus 1, FIG. 2 is an enlarged view of a portion A in FIG. 1, and FIG. 3 is a top plan view of the cooling apparatus.

[0096] The cooling apparatus 1 boiling and condensing refrigerant according the first embodiment has provided therein a refrigerant tank portion 1A for storing therein a refrigerant, a heat exchanging portion 1B for executing heat exchange between the refrigerant, that boils by being heated by heat generated from a heat generating element 2 in the refrigerant tank portion 1A, and a cooling medium, and a refrigerant diffusing portion 1C for diffusing the vaporized refrigerant flowing thereinto from the refrigerant tank portion 1A via the heat exchanging portion 1B (refer to FIG. 2 for those constituent portions that have been just described), and, as shown in FIG. 1, has a stacked construction formed by stacking a plurality of pressed members (plate-like members of the invention).

[0097] Th...

second embodiment

[0127] (Second Embodiment)

[0128] A second embodiment is an example in which inner fins 14 are inserted in both or either of refrigerant passages and cooling water passages formed in a heat exchanging portion 1B.

[0129]FIG. 10 shows an example in which inner fins 14 are inserted into the cooling water passages (second openings 6), and FIG. 11 shows an example in which inner fins 14 are inserted into the refrigerant passages (first openings 5). The heat conducting surface area can be expanded with the inner fins 14 to thereby improve the cooling performance of the cooling apparatus.

[0130] In addition, for example, as shown in FIGS. 12 and 13, the inner fins 14 may be formed into configurations having an elasticity. As this occurs, in inserting the inner fins 14 into the refrigerant passages or the cooling water passages, as the inner fins 14 can be inserted while being compressed, there is no risk that the inner fins 14 are hooked at intermediate positions along the length of the pas...

third embodiment

[0131] (Third Embodiment)

[0132]FIG. 14 shows plan views of pressed members 3E, 3F.

[0133] A third embodiment describes an example in which the configurations of first openings 5, which form refrigerant passages in the pressed members 3E, 3F which are used in a heat exchanging portion 1B, will be discussed.

[0134] While the first openings 5 in the first embodiment are formed into the elongated hole-like configuration (refer to FIG. 5), first openings 5 in this third embodiment will be formed into a group of opening holes which is constituted by a number of circular holes 5a (alternatively, a number of rectangular holes may be used).

[0135] According to this construction, when compared with the first embodiment, as the condensing surface area of the heat exchanging portion 1B is increased due to an increase in the number of the pillar portions 3C which divide the first openings 5 into the number of circular holes 5a, the cooling performance can be increased.

[0136] In addition, accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com