Energy-saving and environmental-friendly inferior ceramic dust-free treatment recycling device

An energy-saving, environmentally-friendly, low-quality technology, applied in grain processing, clay preparation equipment, chemical instruments and methods, etc., can solve problems such as time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

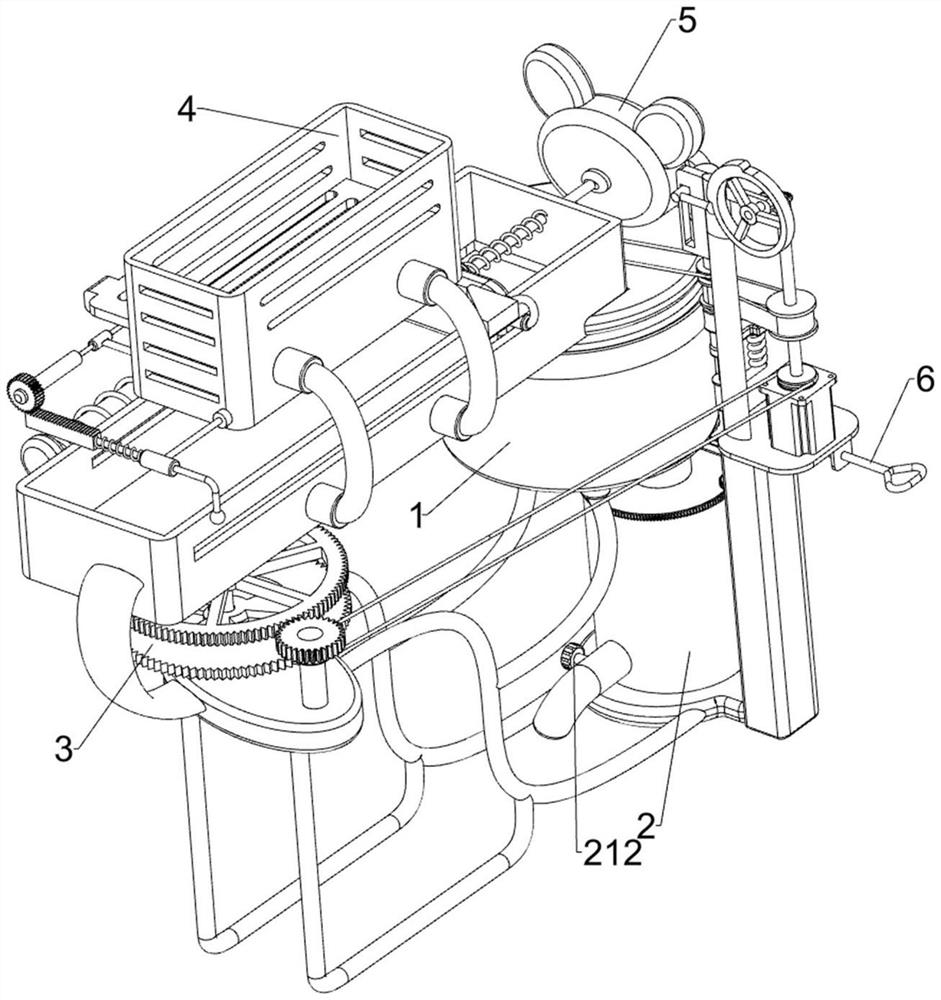

[0053] A dust-free treatment and recycling device for inferior ceramics for energy saving and environmental protection, such as figure 1 As shown, a crushing mechanism 1 and a stirring mechanism 2 are included, and the crushing mechanism 1 is connected with the stirring mechanism 2 .

[0054] The staff can place the ceramics in the crushing mechanism 1, start the operation of the crushing mechanism 1 to crush the ceramics, and at the same time, the operation of the crushing mechanism 1 drives the operation of the stirring mechanism 2 to stir the crushed ceramics. After the stirring is completed, the staff recycles it , all processing is completed, and the operation of the crushing mechanism 1 is stopped.

Embodiment 2

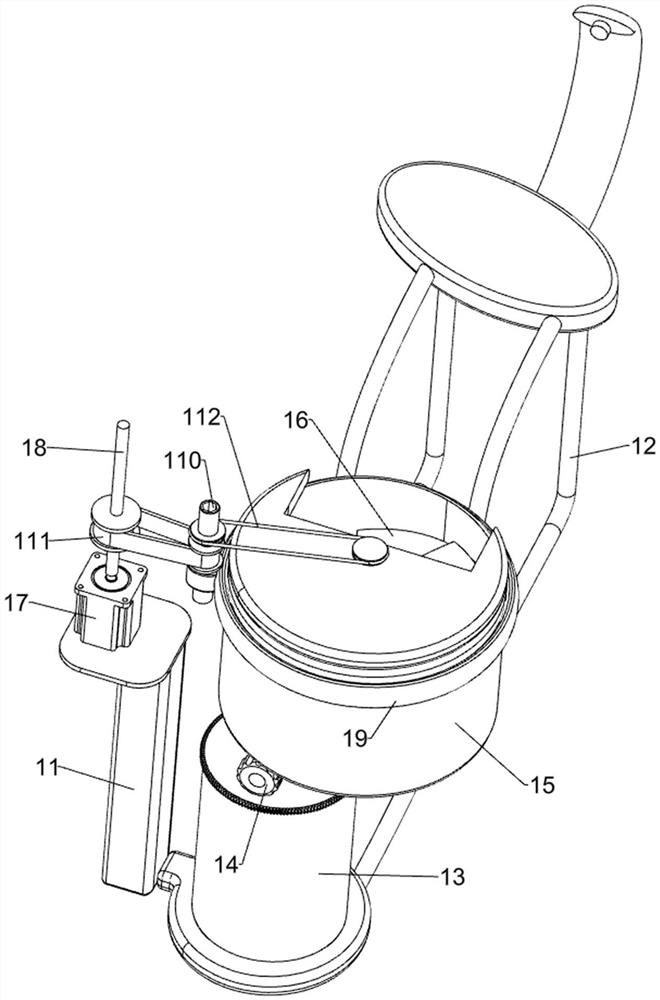

[0056] On the basis of Example 1, such as Figure 1 to Figure 3 As shown, the crushing mechanism 1 includes a support column 11, a fixed frame 12, a fixed barrel 13, a first switch 14, a crushing barrel 15, a crushing rod 16, a motor 17, a first rotating shaft 18, a water pipe 19, a second rotating shaft 110, and a second rotating shaft 110. A transmission assembly 111 and a second transmission assembly 112, the right side of which is provided with a support column 11, the lower part of the support column 11 is provided with a fixed bucket 13, the left side of the lower part of the support column 11 is connected with a fixed frame 12, and the middle part of the fixed frame 12 is connected with a crushing bucket 15. A first switch 14 is rotatably connected between the bottom of the crushing barrel 15 and the top of the fixed barrel 13. The bottom of the inner wall of the crushing barrel 15 is rotatably connected with a crushing rod 16. The top of the support column 11 is provide...

Embodiment 3

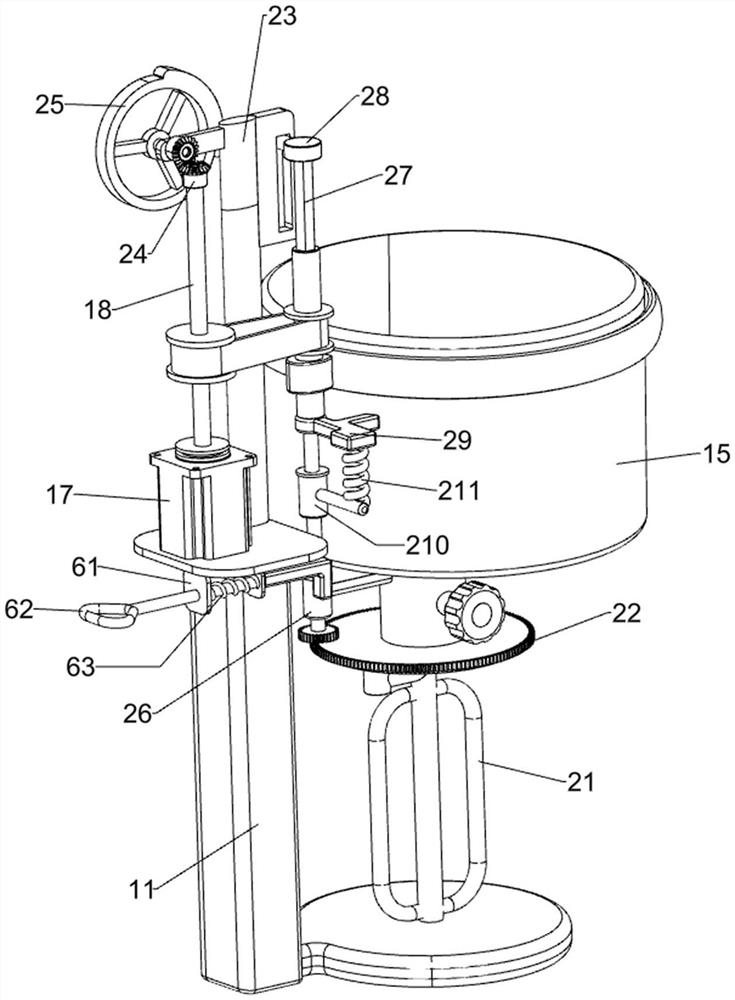

[0060] On the basis of Example 2, such as Figure 4 to Figure 6 As shown, a push mechanism 3 is also included, and the push mechanism 3 includes a straight tooth group 31, a third transmission assembly 32, a missing gear 33, a push box 35, a second fixed rod 36, a push block 37, a second spring 38, a tooth Bar 39 and inclined block bar 310, fixed frame 12 top rotations are connected with straight tooth group 31, and the third transmission assembly 32 is connected between the front side rotation shaft of straight tooth group 31 and the output shaft of motor 17, and the rear of straight tooth group 31 The side rotation shaft is connected with missing gear 33, the left side of the fixed mount 12 top is connected with push box 35, and the rear side of push box 35 is connected with second fixed rod 36, and the second fixed rod 36 is slidably connected with push block 37. Block 37 is slidably connected with push box 35, and the left side of push block 37 is connected with second fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com