Apparatus and method for reducing hydrofoil cavitation

a technology of apparatus and hydrofoil, applied in the direction of special-purpose vessels, vessel construction, transportation and packaging, etc., can solve the problems of sapping the ship and rudder's momentum, significant drag in the boundary layer, etc., to reduce turbulence close, increase the speed of passing water, and reduce the effect of turbulence and eddies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described as it applies to its preferred embodiment. It is not intended that the present invention be limited to the described embodiment. It is intended that the invention cover all modifications and alternatives, which may be included within the spirit and scope of the invention.

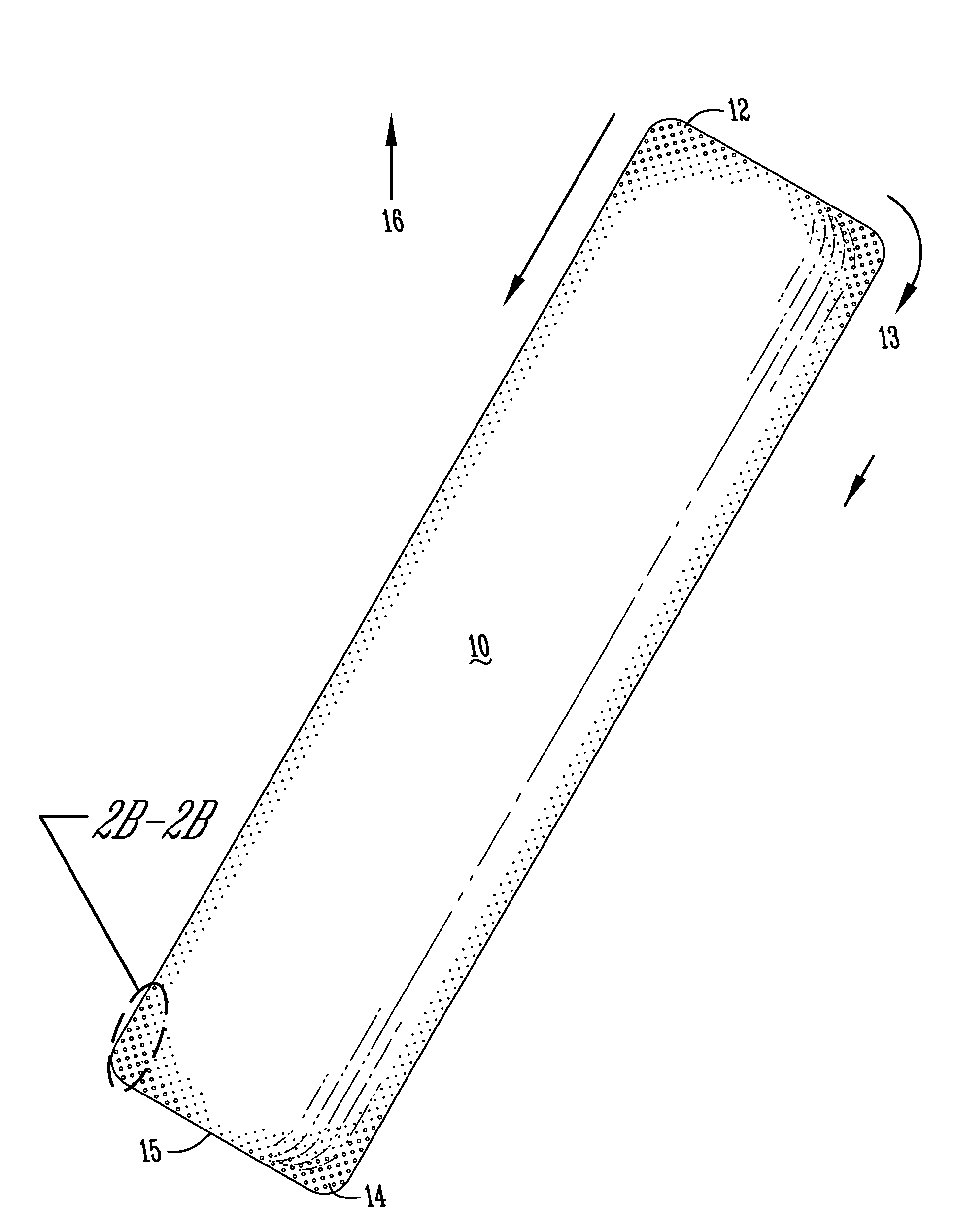

[0038] Referring to FIG. 1, FIG. 1A describes an embodiment in which the entire rudder 10 is covered by alternating round-hole perforations 11, as magnified in 1B. The technique of drilling holes is well known in the art. In this case the rounded perforations would result in a dimpled surface (FIG. 3A), capable of evenly pressurizing the suction side as well as augmenting surface turbulence and reducing boundary layer drag on the pressure side (from water passage through the holes).

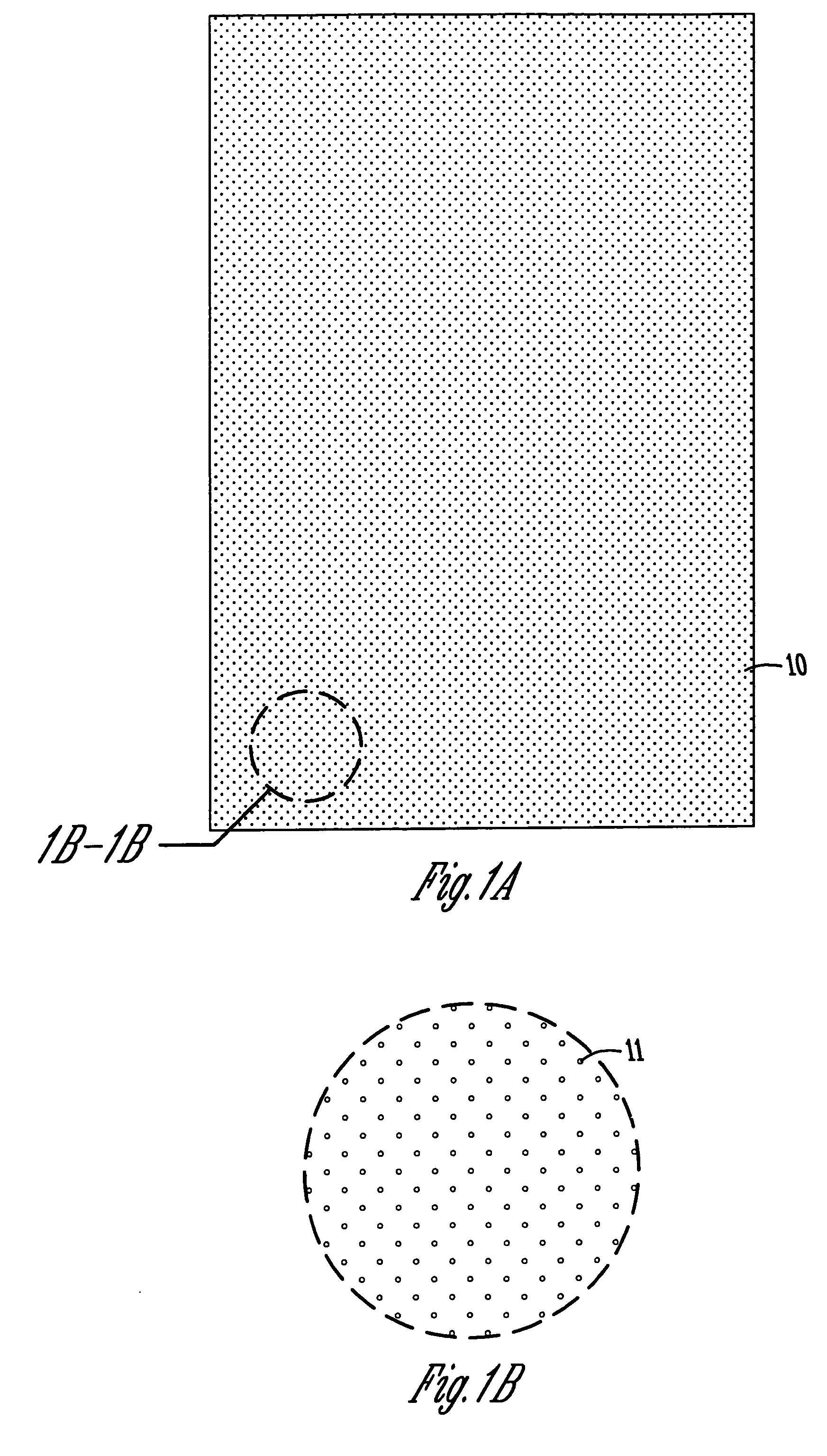

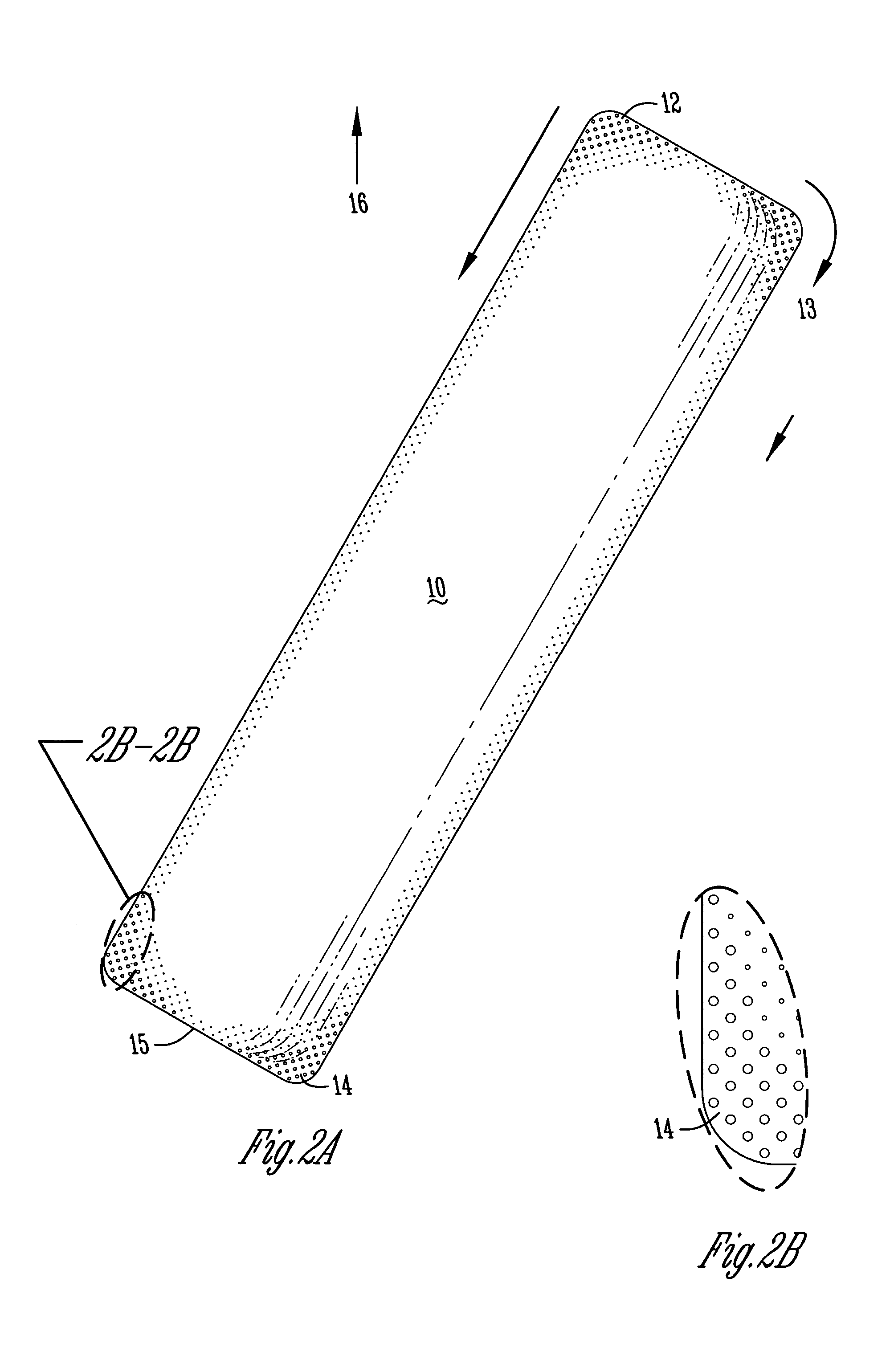

[0039] In the FIG. 2 bottom rudder view, this embodiment illustrates surface texture minimizing leading edge cavitation and trailing edge cavitation, without perforations. Rudder 10 has a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com