Method, apparatus, system, method and device for data creating, and program for mounting electronic component

a technology for electronic components and circuit boards, applied in the direction of soldering devices, manufacturing tools,auxillary welding devices, etc., can solve the problems of reducing the quality of the circuit board on which electronic components are mounted, generating bridges between electronic components, and affecting the quality of the circuit board. achieve the effect of improving the self-alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

[0142] Next, description will be given to the electronic component mounting method according to the invention.

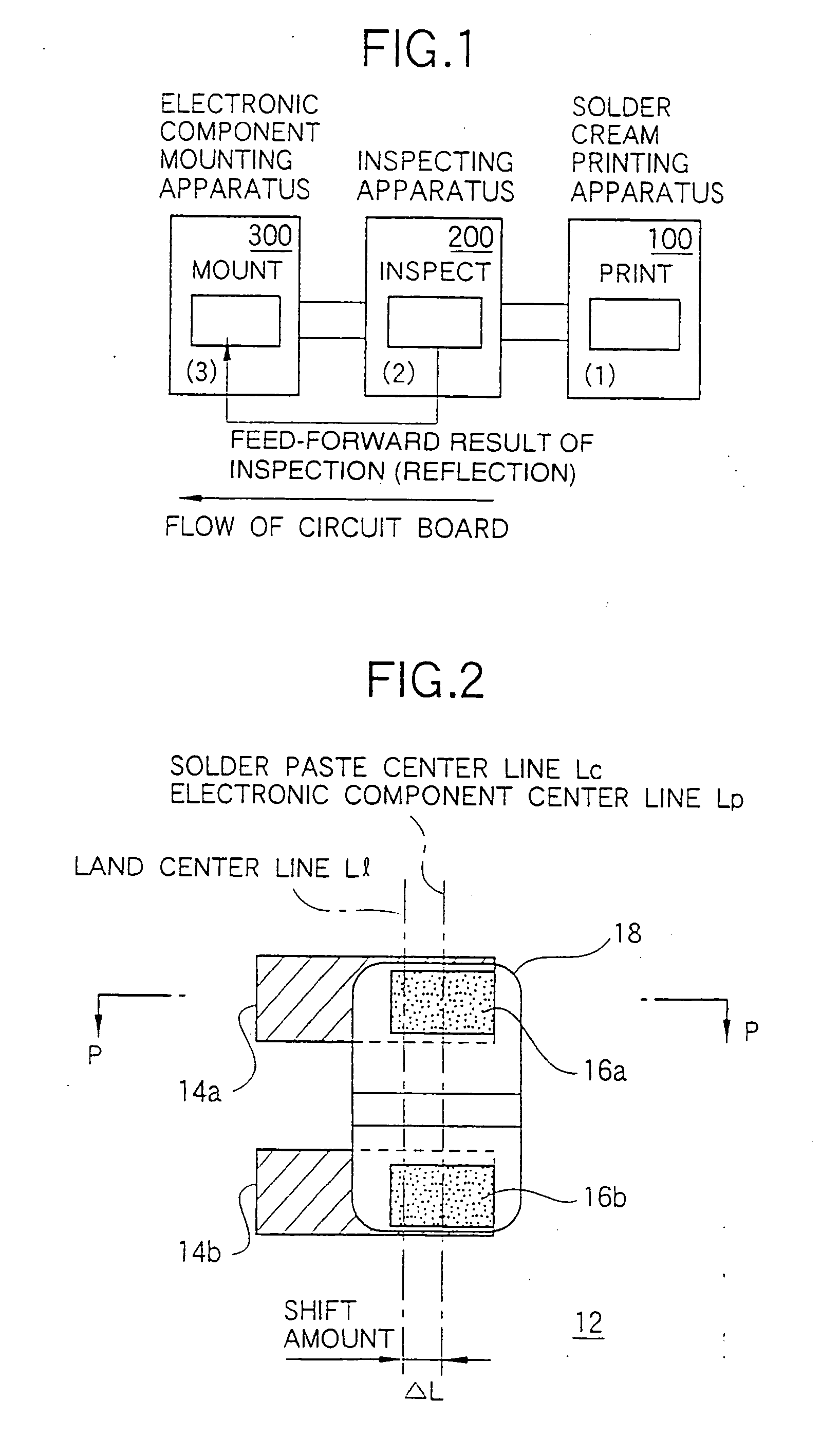

[0143] While the position of the land and the printing position of the solder paste are detected every electronic component for each electronic component to be mounted on the circuit board and the shift amounts thereof are obtained to change the mounting position of the electronic component in the first embodiment, a shift amount between the position of a land and the position of a printed solder paste is obtained for all the electronic components to be mounted on the circuit board and an average value of the shift amount for each electronic component is calculated to collectively change the mounting position of the electronic component on the circuit board based on the average value of the shift amount thus obtained in the second embodiment.

[0144] A specific changing procedure will be described below. For example, in the case in which N electronic components are to be moun...

third embodiment

[0152] Next, description will be given to the electronic component mounting method according to the invention.

[0153] While the amount of the shift of the solder paste printed on the circuit board from the land is averaged and the target mounting position is changed in one way with respect to all the electronic components in the second embodiment, the circuit board is divided into the optional number of blocks, and the average value of a shift amount is obtained for each block and the mounting position of the electronic component is changed for each block by using the average value of each block thus obtained in the third embodiment.

[0154] A pattern for dividing the circuit board into the optional number of blocks includes a dividing pattern shown in FIG. 18, for example. FIG. 18(a) shows an example in which the circuit board is divided annularly into regions from the peripheral edge of the circuit board toward a center and FIG. 18(b) shows an example in which the circuit board is d...

fourth embodiment

[0158] Next, description will be given to the electronic component mounting method according to the invention.

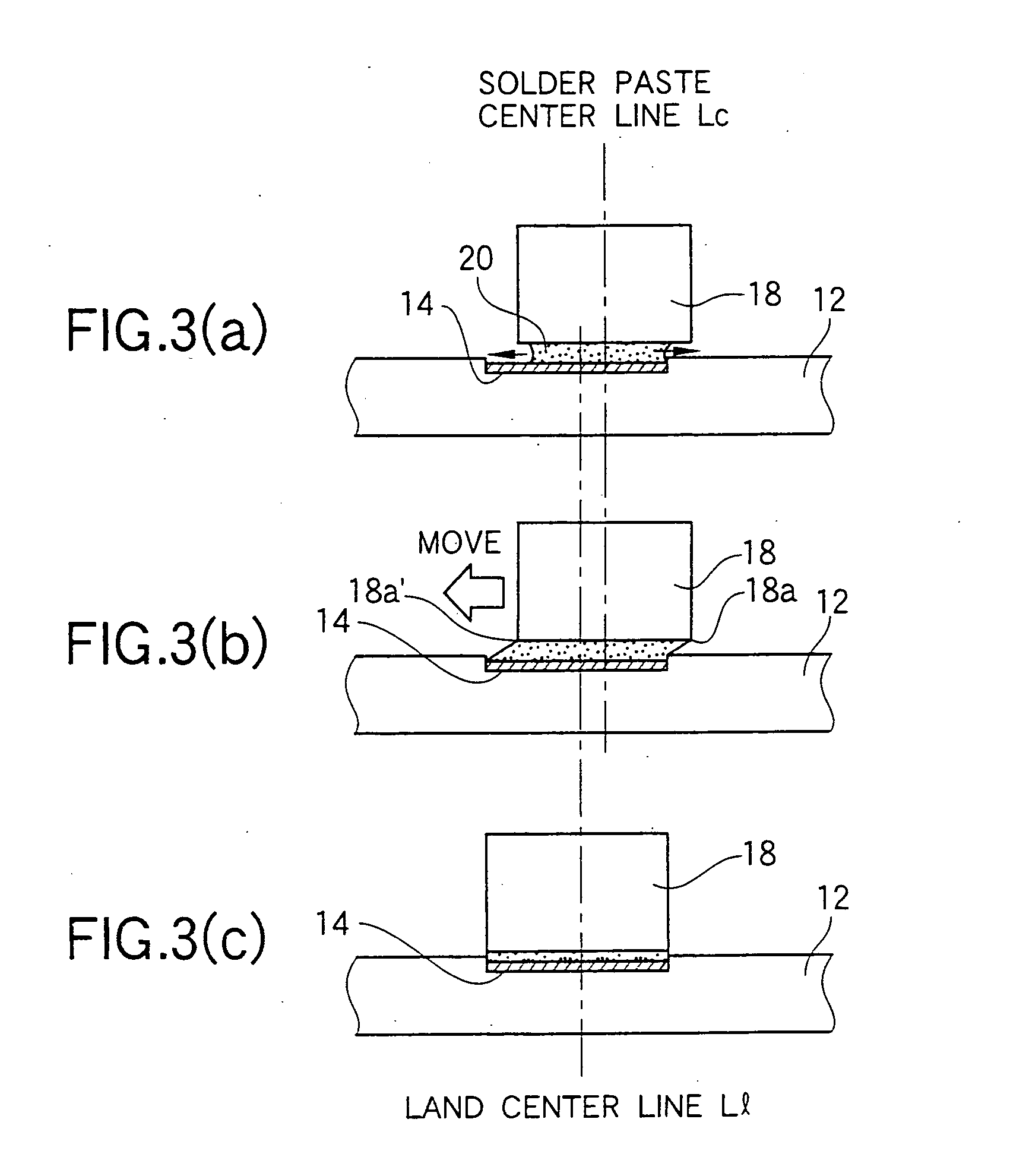

[0159] In the embodiment, as shown in FIG. 19, various parameters such as the weight and shape of an electronic component to be mounted, the material composition of a solder paste to be used, a friction property, a viscosity, a solder powder size, a melting point, a flux component (a resin base, an organism base and an inorganism base), a flux activity or a printing thickness are arranged in a table and a self-alignment ratio is assumed depending on the combination of the type of an electronic component to be actually used and the material of the solder paste by utilizing the table. The self-alignment ratio represents an index indicating, as a percentage, the degree of a shift from the center of the printed solder paste that self-alignment is effective. Based on the self-alignment ratio, the degree (for example, 50%, 80% or 100%) of the shift amount of the printing position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com