Hybrid insulating reinforced concrete system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

[0039] For the purposes of the present disclosure, several definitions are necessary:

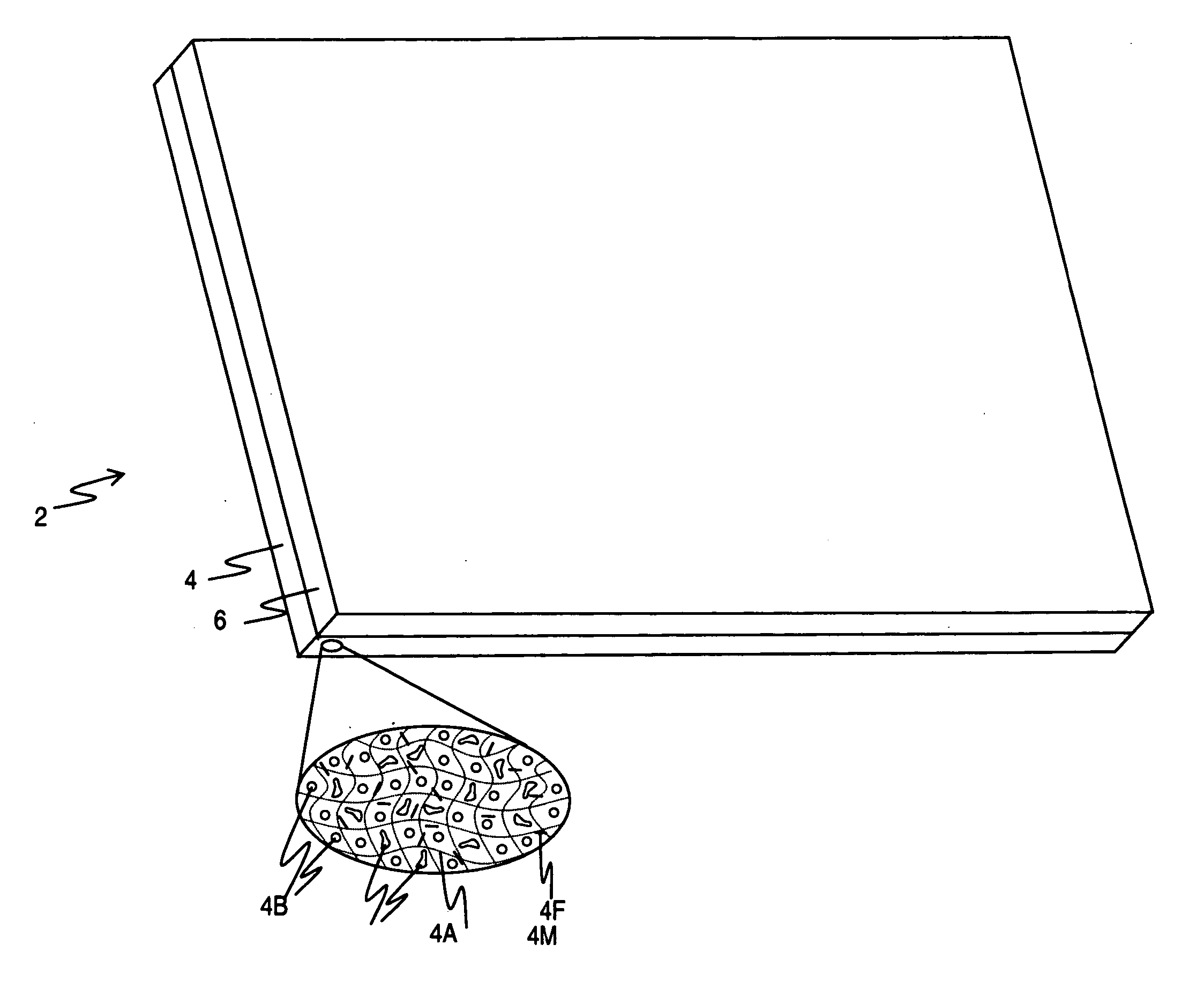

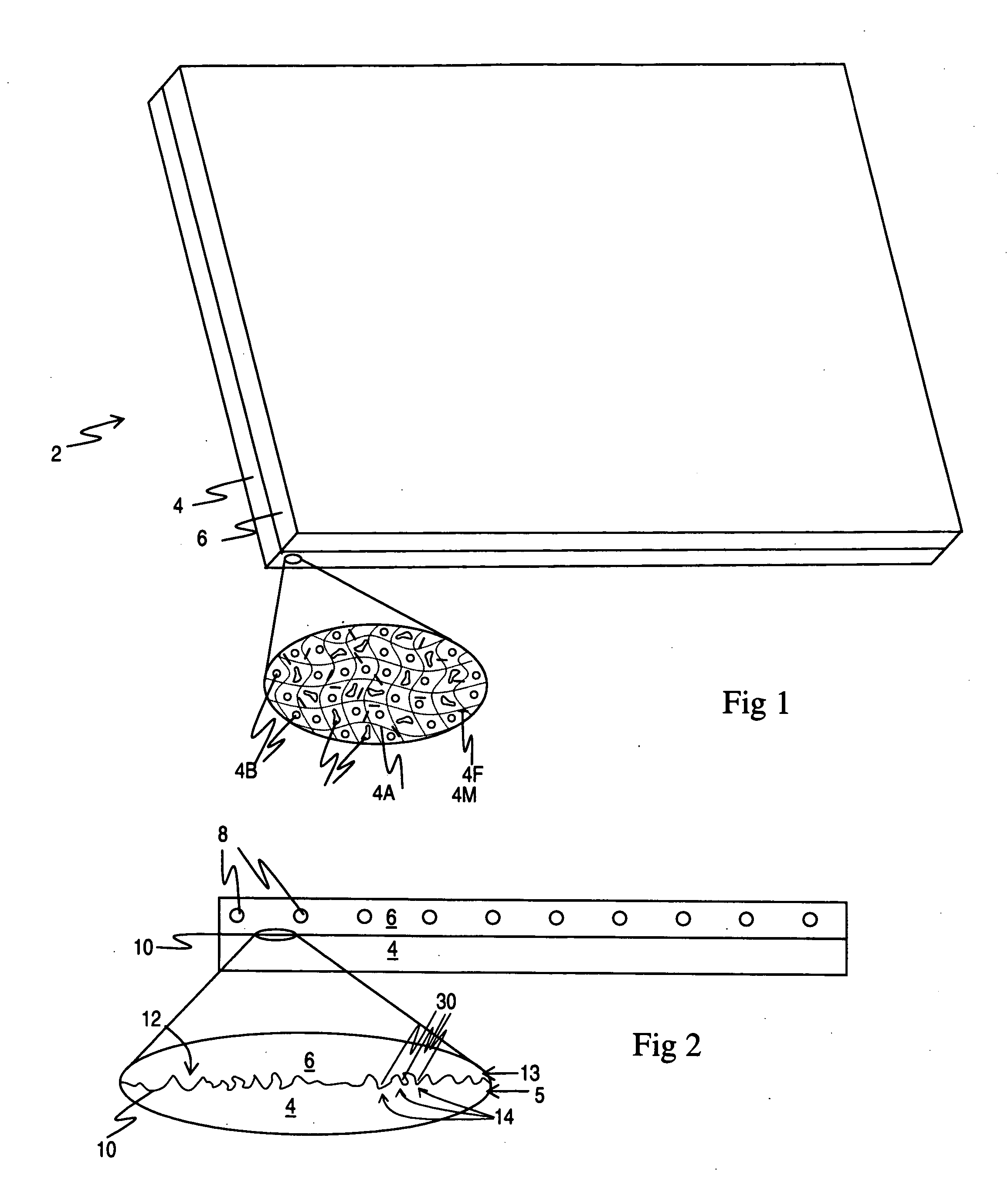

[0040] Element—the pre-cast insulating concrete shape.

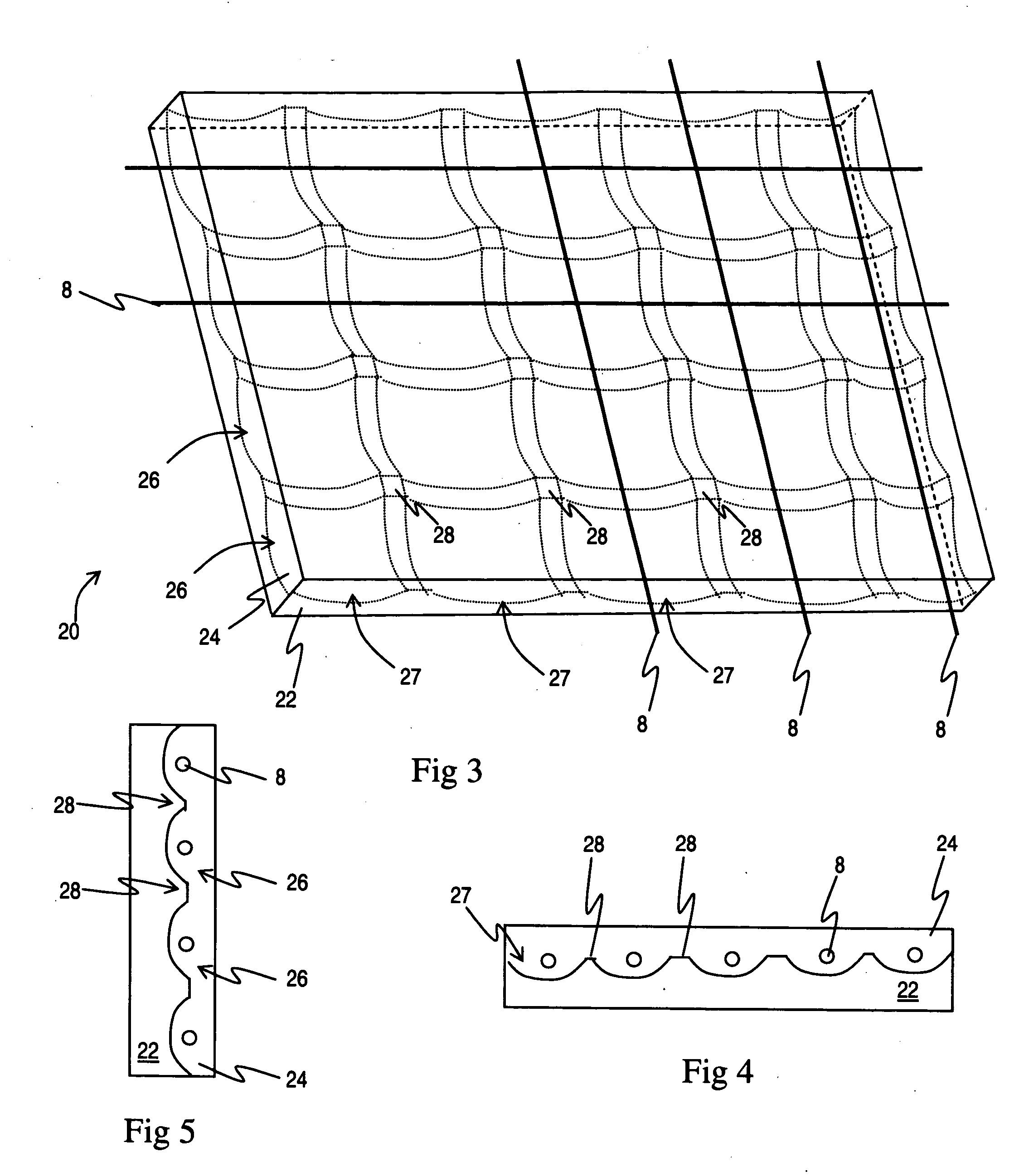

[0041] Panel—when a number of the Elements are bonded or otherwise connected together they form a large-scale insulating concrete Panel—either Planar or Shaped.

[0042] Component—when the Panel and the reinforcement and structural concrete are all assembled together the result is a large-scale construction Component.

[0043] Insulating Concrete—an engineered low-density concrete with the same characteristics of expansion / contraction as structural concrete, with a sufficiently large pore size which enables cement paste from the wet structural concrete to become embedded within the surface of the insulating concrete thus forming a continuous bond between the two surfaces. Insulating Concrete resists heat and sound transmissions in particular.

[0044] Insulated Concrete—a structural or other type of concrete to which an insulating layer of polystyre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com