Method and apparatus for exhaust gas recirculation cooling using a vortex tube to cool recirculated exhaust gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

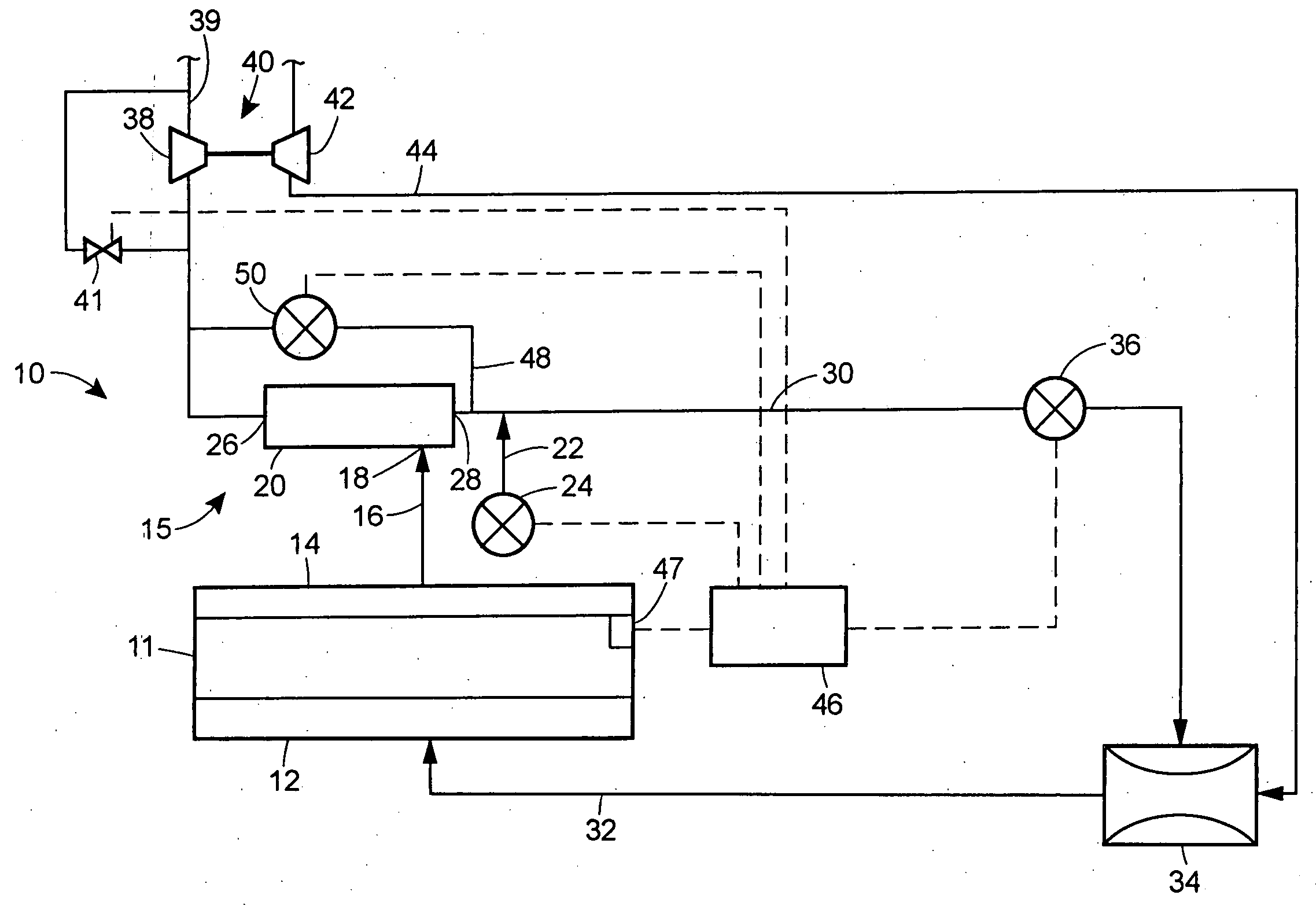

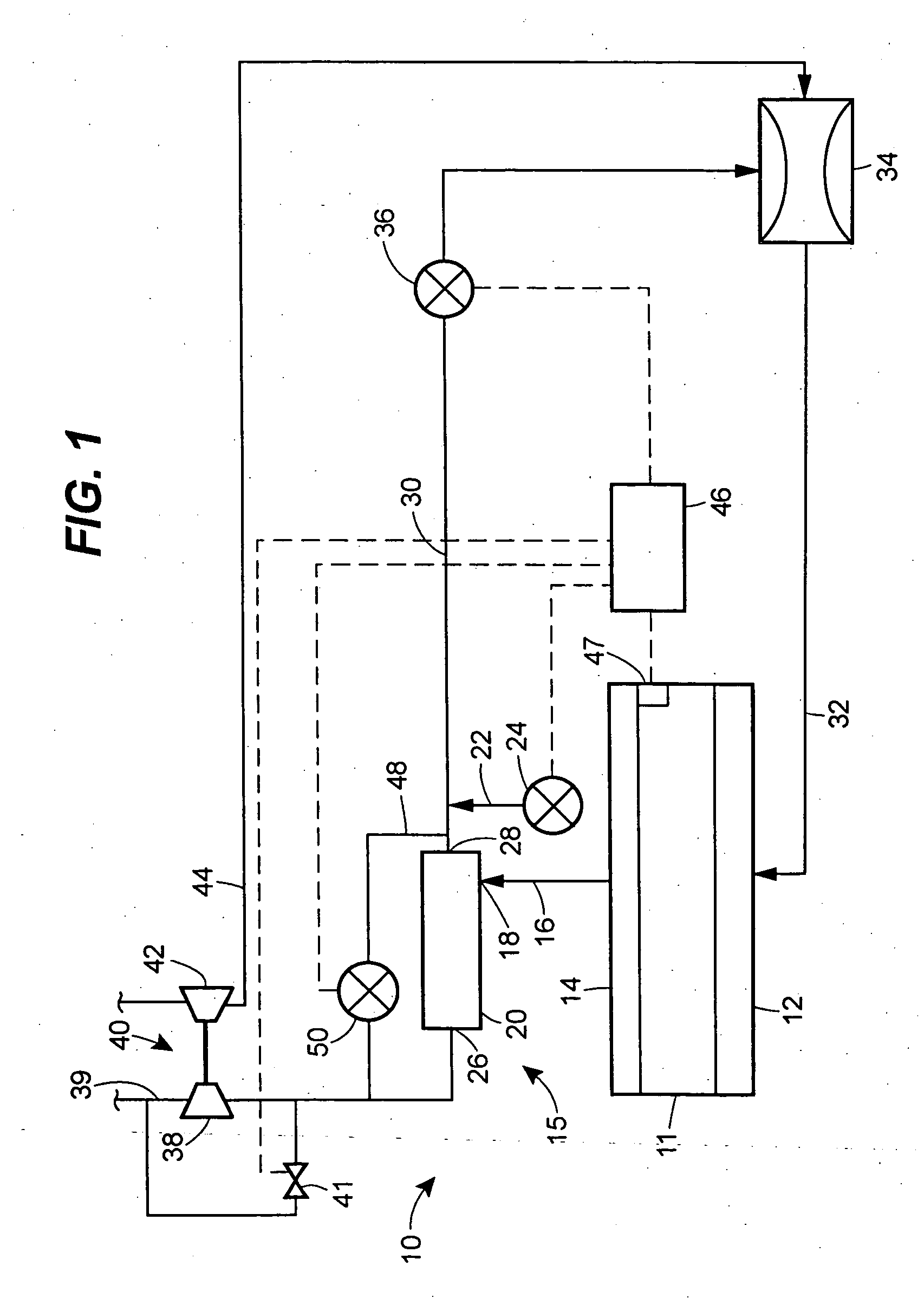

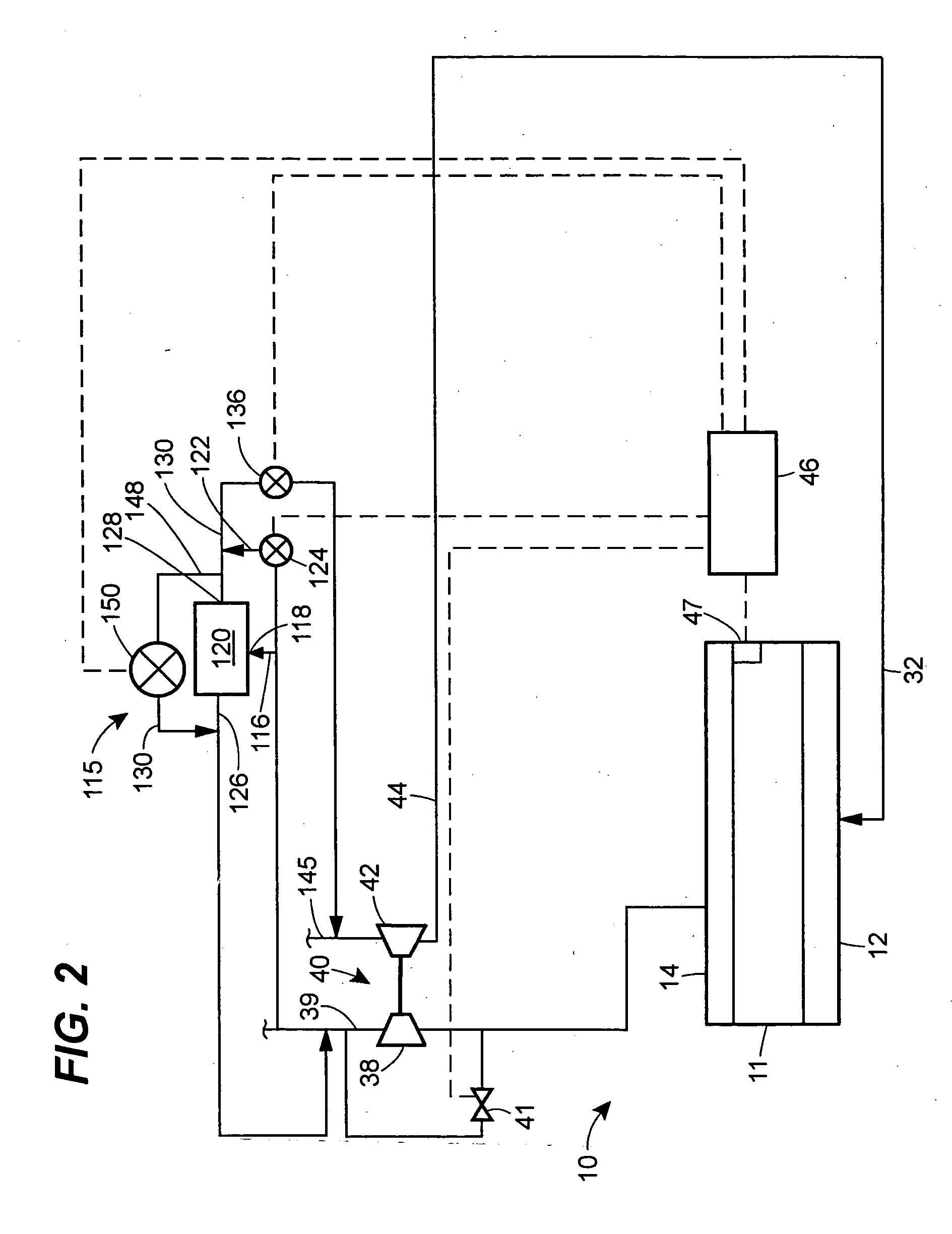

[0012] With reference to FIG. 1, an engine, shown schematically, and generally indicated at 10, may include a combustion chamber 11, an intake manifold 12 and an exhaust manifold 14. The engine 10 may further include means 15 for recirculating exhaust gases, which may include a primary exhaust gas recirculation conduit 16 in fluid communication with the exhaust manifold 14. The primary exhaust gas recirculation conduit 16 may also be in fluid communication with an inlet 18 of a vortex tube 20. The primary exhaust gas recirculation conduit 16 may also optionally be in fluid communication with a bypass conduit 22 having a bypass valve 24 therein. The vortex tube 20 includes a hot gas outlet 26 and a cold outlet 28 and may be capable of diverting relatively hot exhaust gases to the hot gas outlet 26, and relatively cold gas exhaust gases to the cold gas outlet 28.

[0013] The cold gas outlet 28 of the vortex tube 20 may be placed in fluid communication with a cold exhaust gas recirculat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap