Bidimensional detector of ionizing radiation and manufacturing process for this detector

a detector and ionizing radiation technology, applied in radiation measurement, instruments, electrical equipment, etc., can solve the problems of unsuitable use, unsuitable for chemical etching, high cost, etc., and achieve the effect of low performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

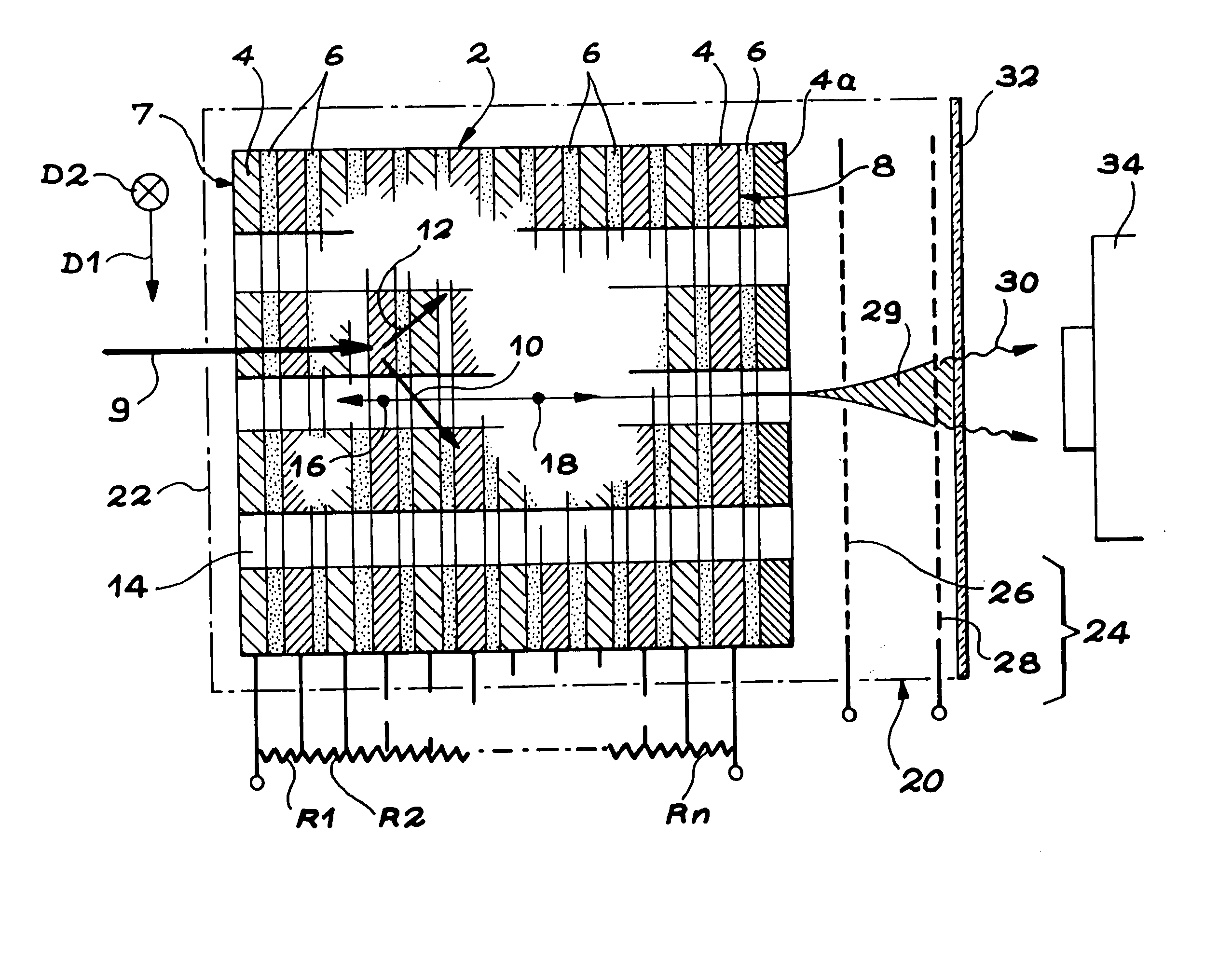

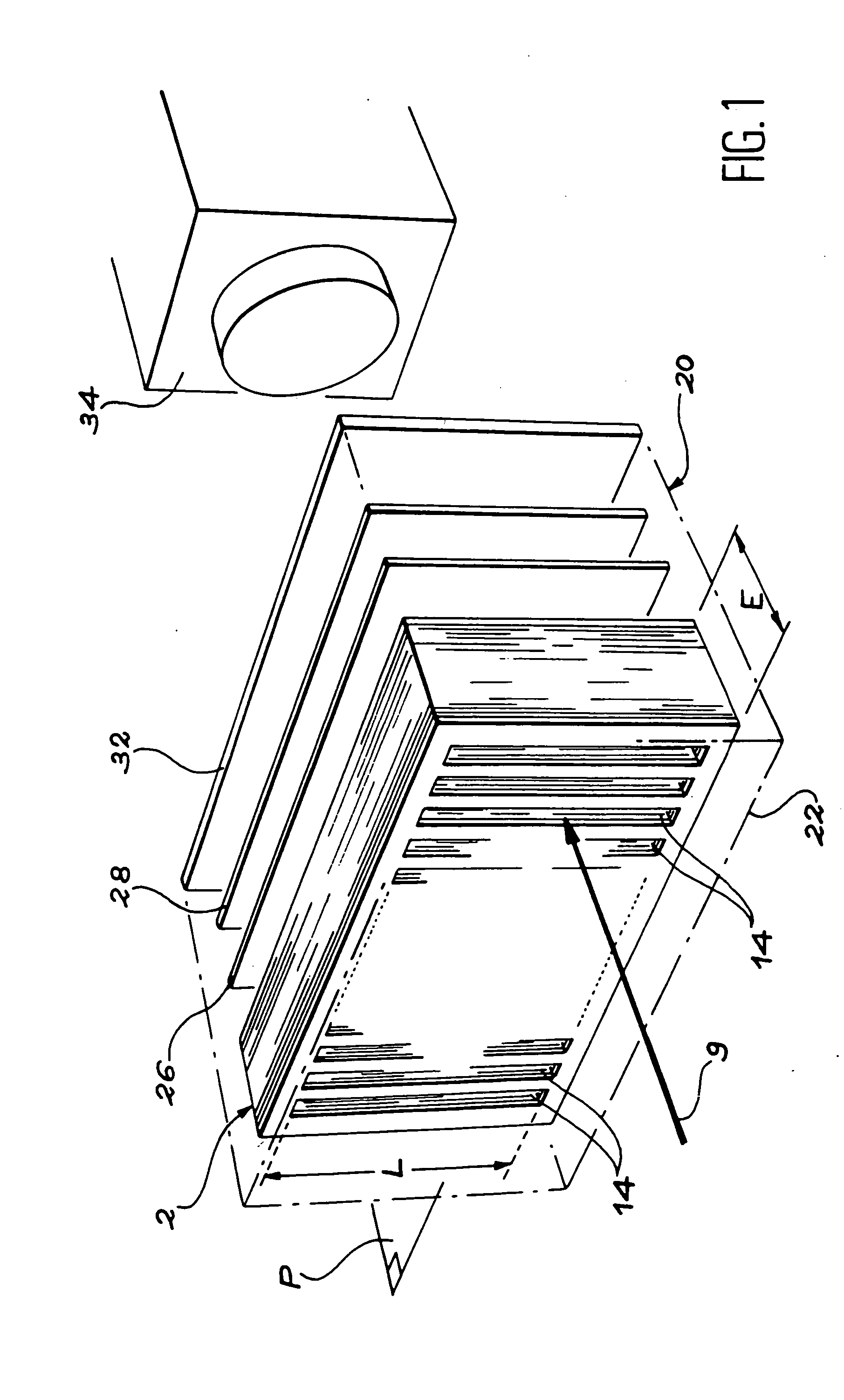

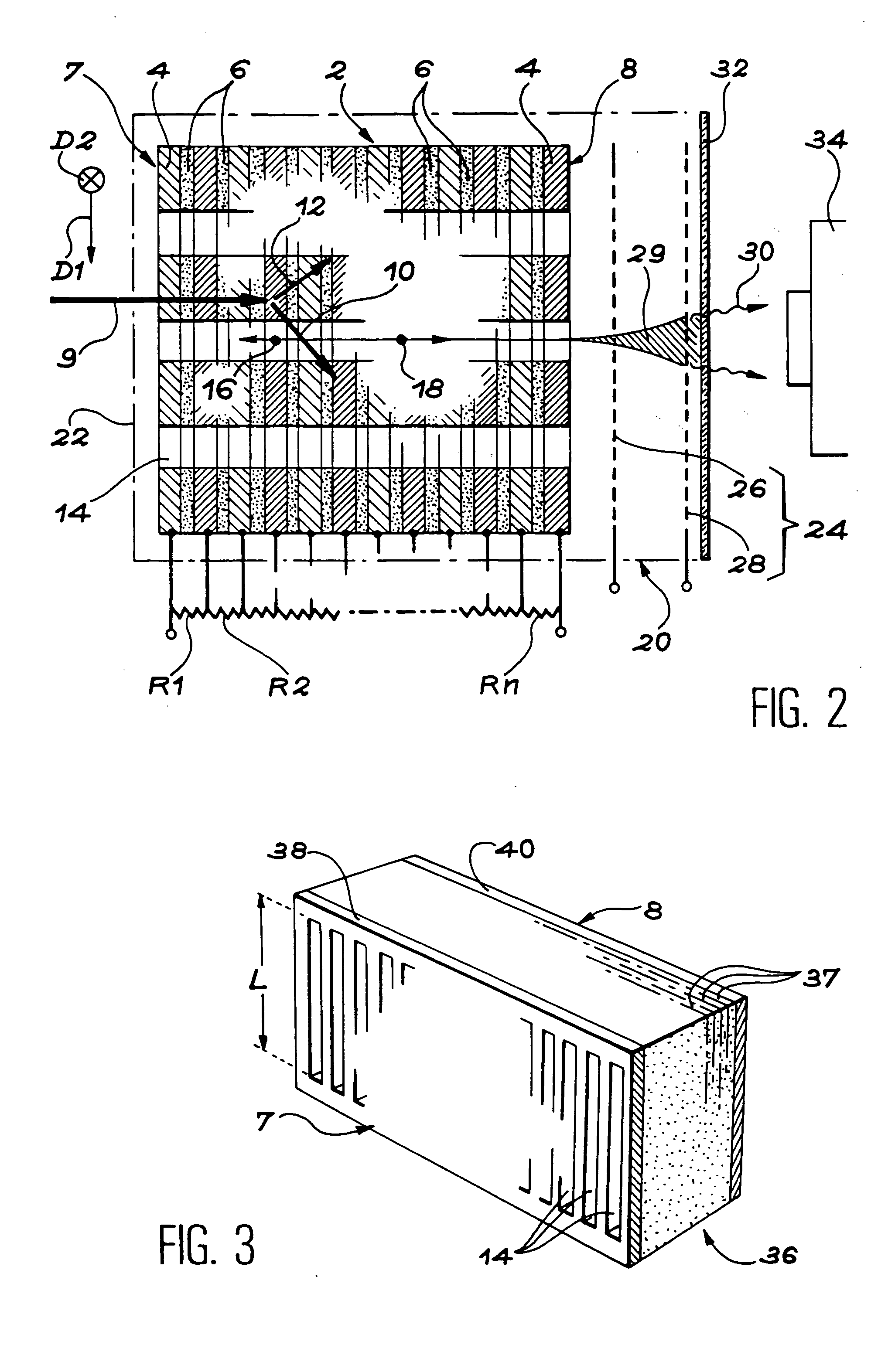

[0060] The bidimensional detector of incident ionizing radiation having an energy greater than, or equal to, 100 keV (as per the precepts of the invention), an embodiment of which is schematically shown in FIG. 1, comprises a block (2) formed from a converting material, offering a high interaction cross section with respect to the incoming ionizing radiation.

[0061] In the case of FIG. 1, this material includes an electrical conductor and, as may be seen on FIG. 2, the block itself is a stack of layers (4) of this material, whereby these layers (4) alternate with electrical insulating layers (6).

[0062] The stack begins with one of the layers (4) in the first face (7) of the block, through which the ionizing radiation penetrates into the block (2). The stack also terminates with one of these layers (4) in the second face (8) of the block, which is located opposite the first face (7).

[0063] In the example shown, the detector is intended to detect X photons which have an energy of 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com