Multi-level, automated vehicle parking structure

a parking structure and multi-level technology, applied in the field of multi-level, automated parking structures, can solve the problems of low steady throughput, inability to meet the needs of vehicles, etc., to solve and achieve the effect of solving the combined problems of rapid vehicle throughput and construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

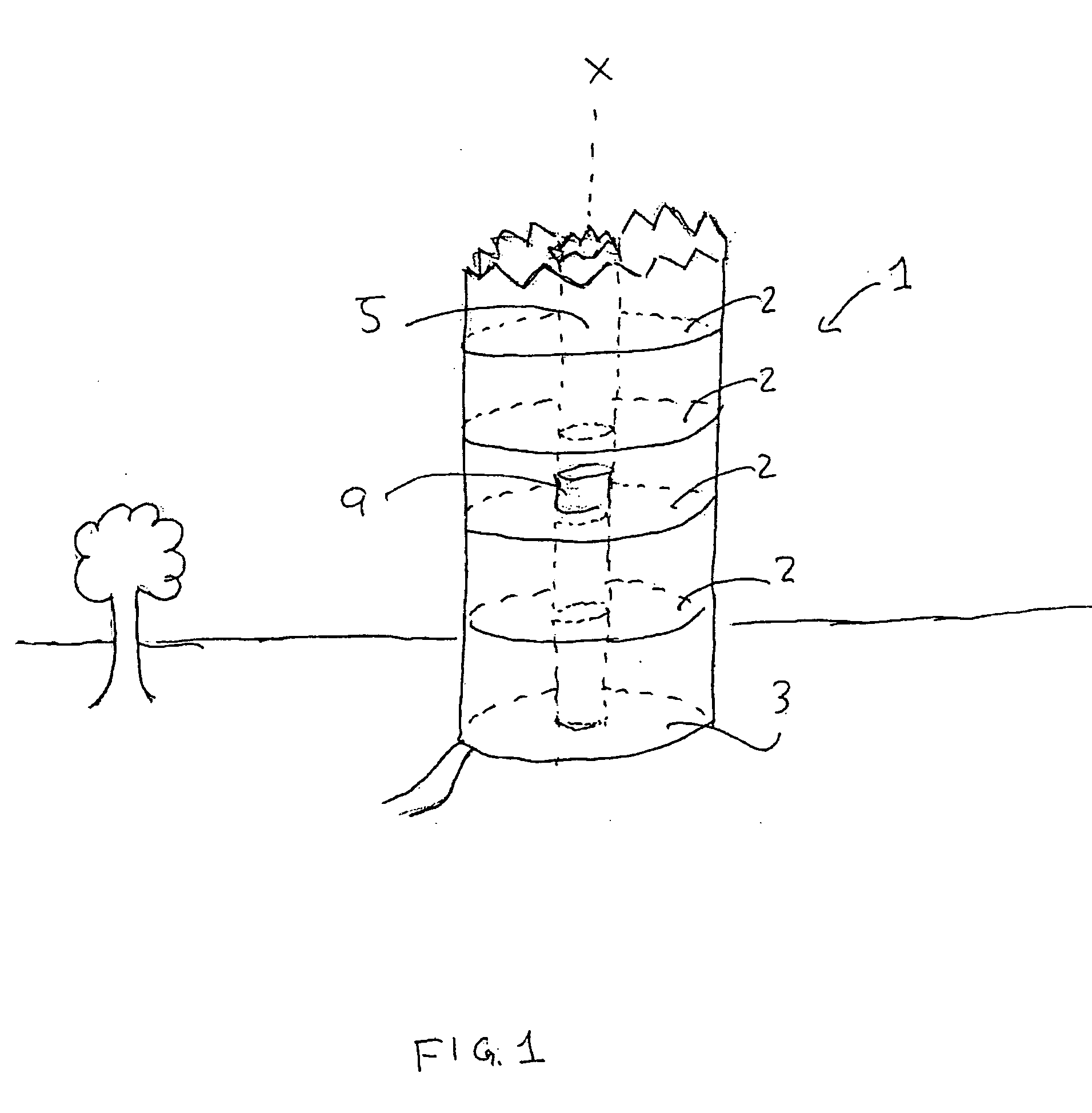

first embodiment

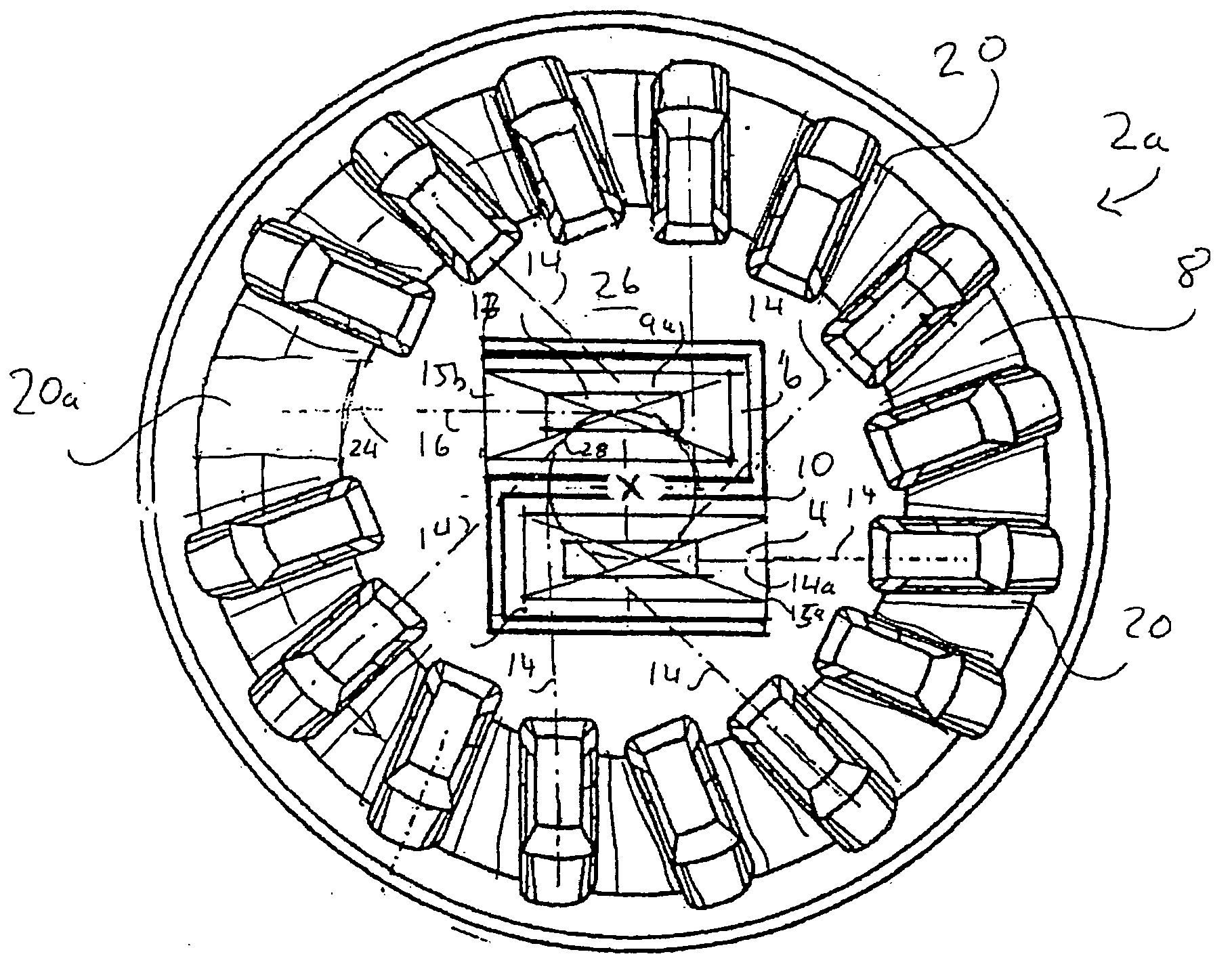

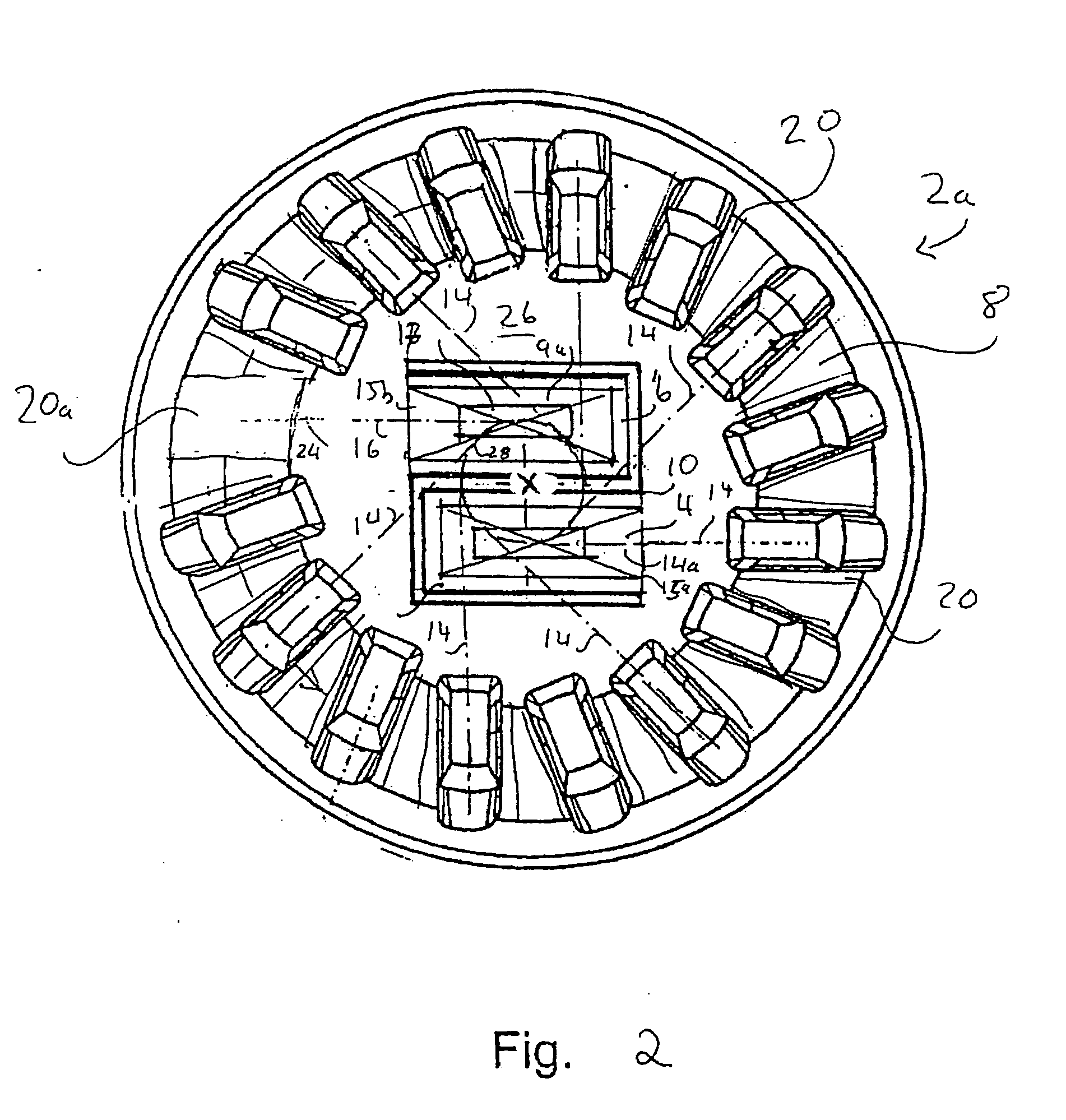

[0062]FIG. 2 shows one embodiment of the parking level 2, generally indicated by 2a. The parking level 2a includes an annular platform 8 rotatable about the central axis X of the installation. Two elevator shafts 4 and 6 are centrally located in an interior central space 26 of the parking level 2a. The elevators 4 and 6 share a common wall 10 that lies on a diameter of the parking level 2a. The elevators 4 and 6 have parallel base centerlines 14a and 14b, respectively, which are off-radial, i.e. neither of which lie on a diameter of the parking level 2a. The elevator shafts 4 and 6 each have an opening 15a and 15b, respectively, at the parking level 2a, facing opposite directions. The annular rotatable platform 8 comprises a plurality of parking spaces 20, having off-radially aligned center base lines, represented by broken lines 14.

[0063] Transferring a vehicle from an elevator car, for example, the elevator car 9a located in the elevator shaft 6, to a vacant parking space 20a tak...

second embodiment

[0066] Further attention is now directed to FIG. 3, illustrating a second embodiment of a parking level 2, generally indicated by 2b, that is part of the parking installation 1. The parking level 2b comprises an inner annular parking platform 54, and a rotatable outer parking platform 56. The parking platforms 54 and 56 are both coaxial with the axis X of the installation 1. The inner platform 54 has a sufficiently large inner diameter to surround a central region 59 including four elevator shafts 64a-64d, each servicing all levels of the installation 1.

[0067] The central region 59 is divided into four quadrants A, B, C and D by a cruciform partition wall 70.

[0068] In each one of the elevators 64a-64d, is an elevator car 9 upon which an electrically-powered motorized dolly 76 is installed. The motorized dolly 76 is loadable by a vehicle to be parked and functions in the same manner previously described, to transfer a vehicle from an elevator car 9 to a vacant parking space 80 that...

third embodiment

[0078]FIG. 5 illustrates another embodiment of a parking level 2, generally indicated by 2c. In this embodiment, the installation 1 comprises two elevators 156a and 156b located within a rotatable central circular region 160 in the interior of an annular stationary platform 162. The elevators 156a and 156b share a common wall 164 that lies on a diameter of the parking level 2c. The elevators 156a and 156b have parallel center base lines 166a and 166b respectively that face in opposite directions that are not radially aligned. The platform 162 comprises a plurality of non-radially aligned parking spaces 166, represented by dashed lines 166. The difference between the present embodiment and that illustrated in FIG. 1 resides in that the platform 162 is stationary and is served by the rotary bank of elevators 156a and 156b.

[0079] The bank of elevators rotates, until they are aligned with a parking space. Although the elevators turn together, they travel vertically quite independently ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com